What are the innovative solutions to minimize microplastic pollution associated with Spandex fabric?

Reducing pollution caused by microplastics from spandex fabrics is a pressing environmental issue that needs to be addressed. Many exciting approaches are currently being considered to find a solution to this problem.

Researchers are focusing on developing elastic fibers that are less likely to shed microplastics during washing. These fibers are biodegradable or durable and can minimize the release of microplastics.

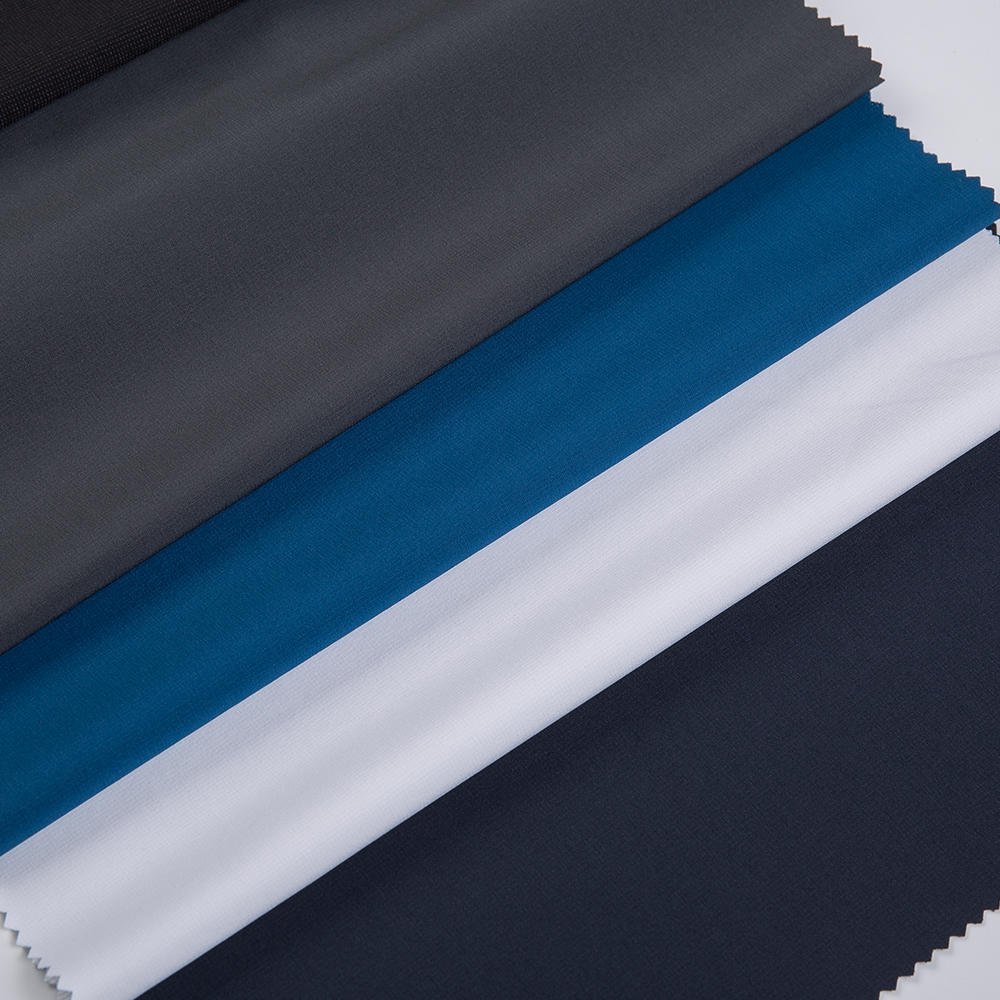

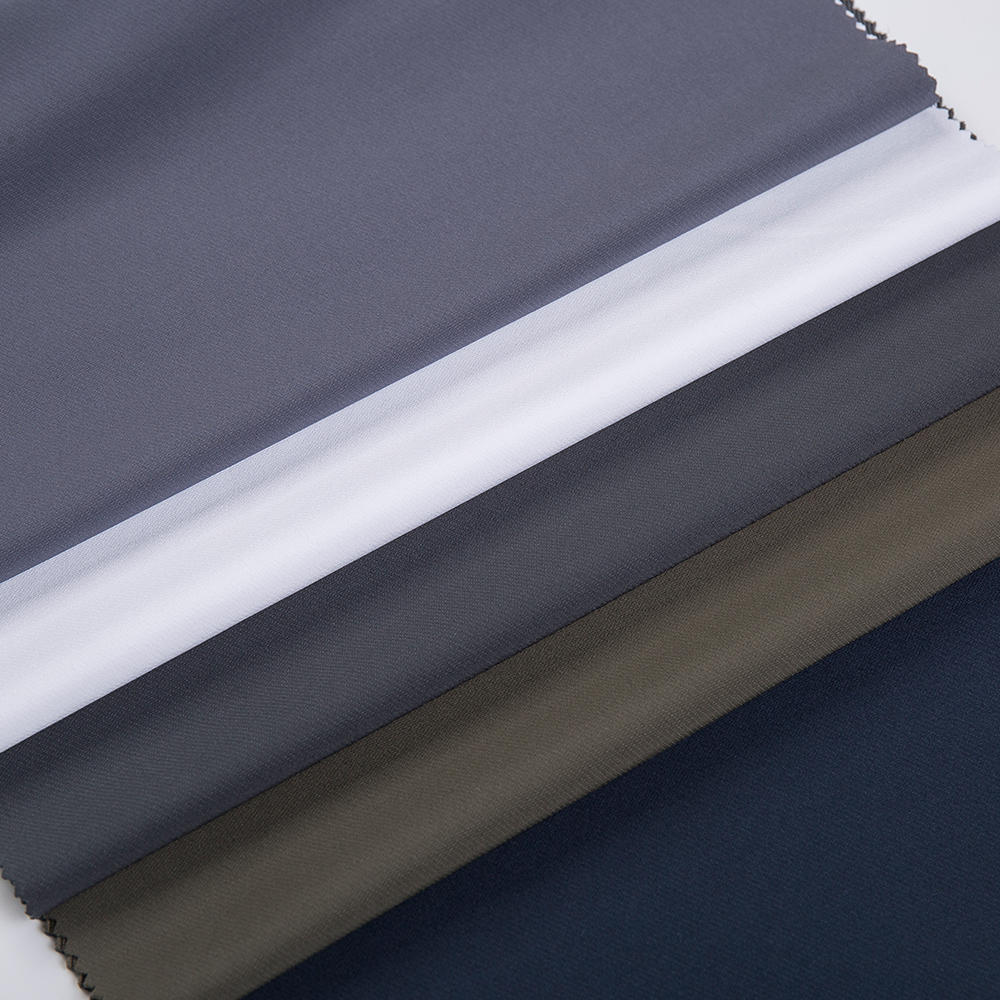

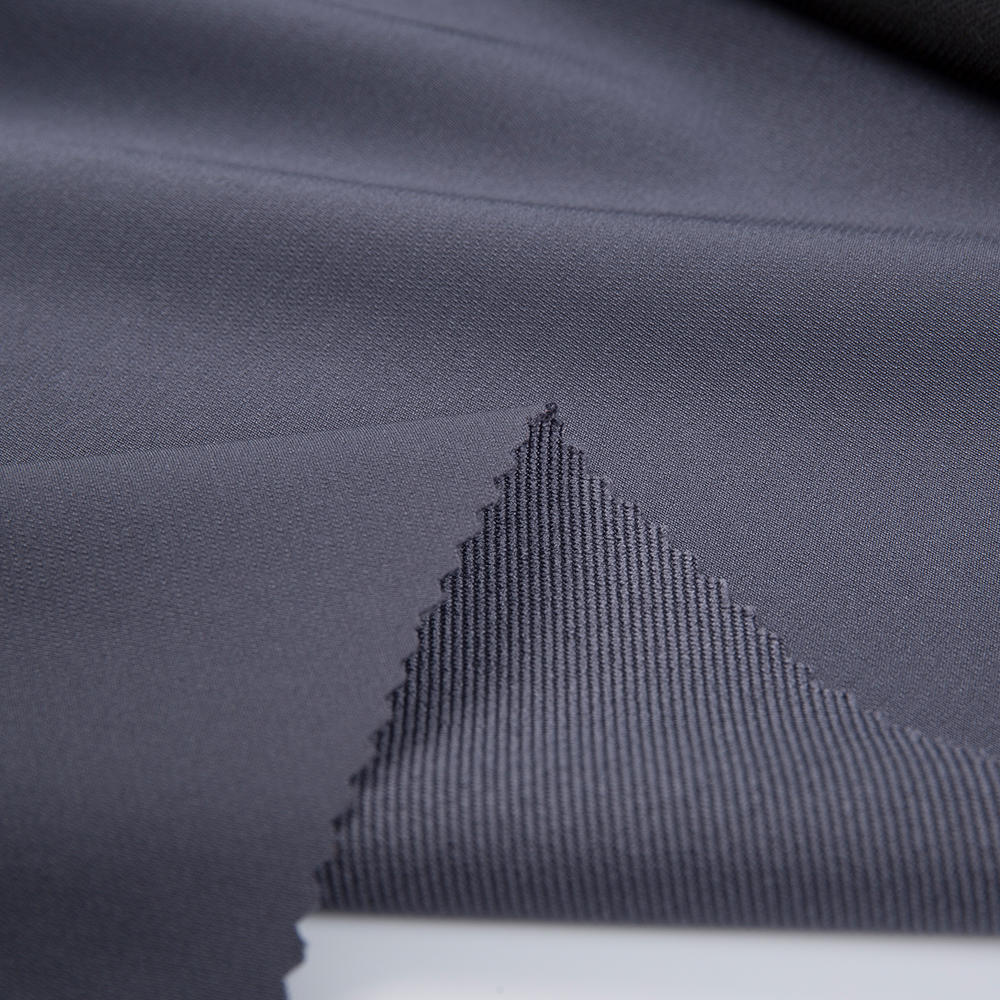

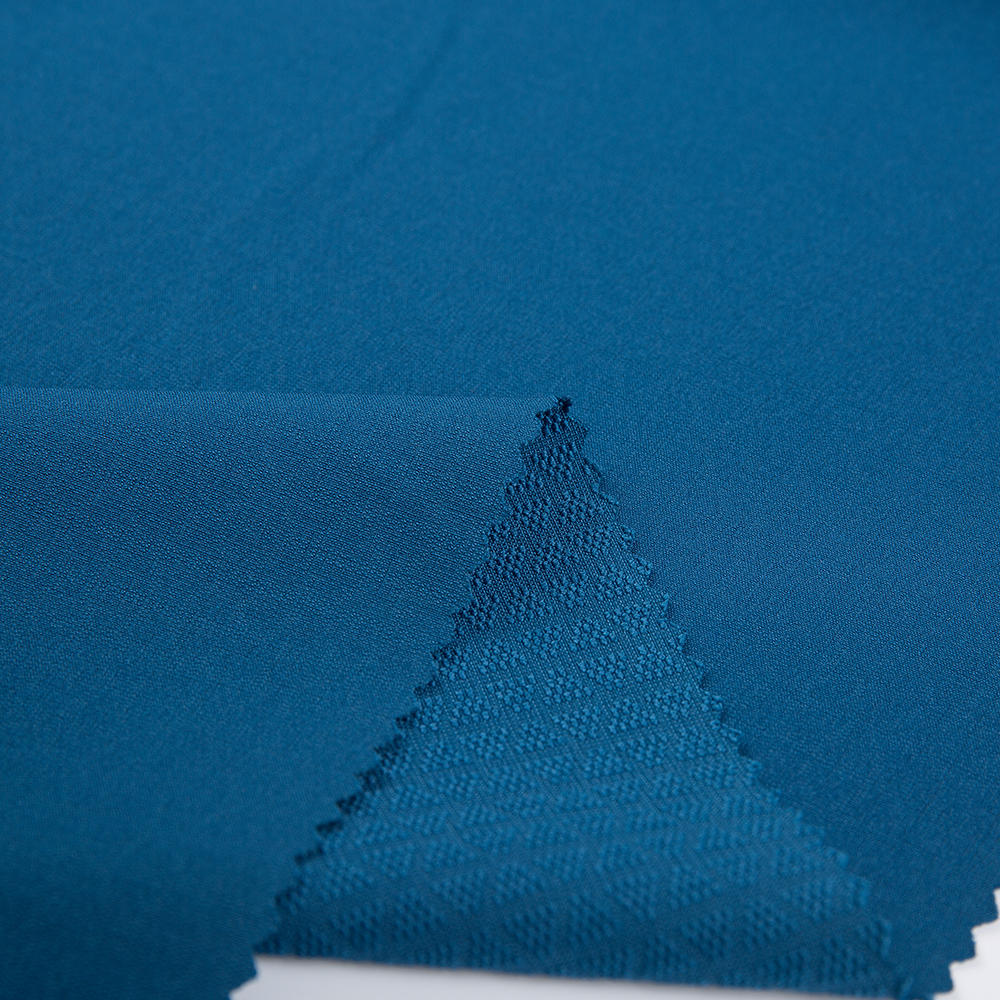

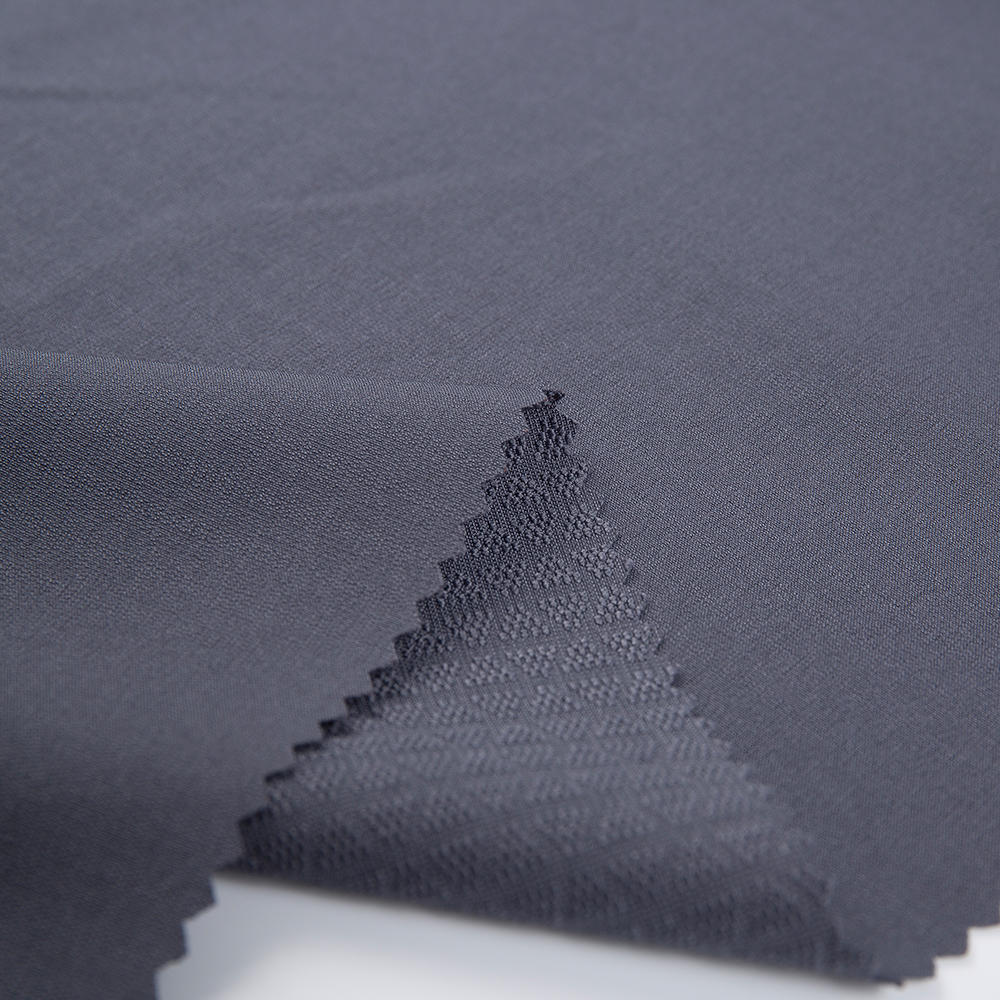

Another area of research is the structure of fabrics. Microfiber shedding can be reduced by changing the weave or using a coating that encapsulates the spandex fibers. This can be achieved by making the weave tighter or adding a protective layer to prevent the release of microplastics during washing.

The development of specialized microfiber filtration systems for washing machines and wastewater treatment plants is also being considered. These systems have the potential to capture microplastics before they enter water bodies, preventing contamination at the source.

Furthermore, by employing environmentally friendly dyeing and finishing processes during the manufacture of spandex fabrics, microplastic emissions can be significantly reduced. It is especially important to reduce the amount of chemicals used in these processes.

Promoting responsible clothing care practices is also an effective way to minimize shedding of microplastics. Encouraging consumers to wash spandex fabrics in cold water, use microfiber filter bags, and avoid overloading washing machines can make a big difference.

Raising consumer awareness of microplastic pollution is essential. Educating and providing information to people about how to reduce microfiber emissions during laundry can promote responsible consumer behavior.

Governments and environmental authorities are also considering laws and regulations to limit microplastic pollution from textiles. This could encourage the textile industry to adopt more environmentally friendly materials and manufacturing processes.

Efforts to recycle and upcycle old spandex-based clothing can also help reduce the demand for new production and limit the release of microplastics into the environment.

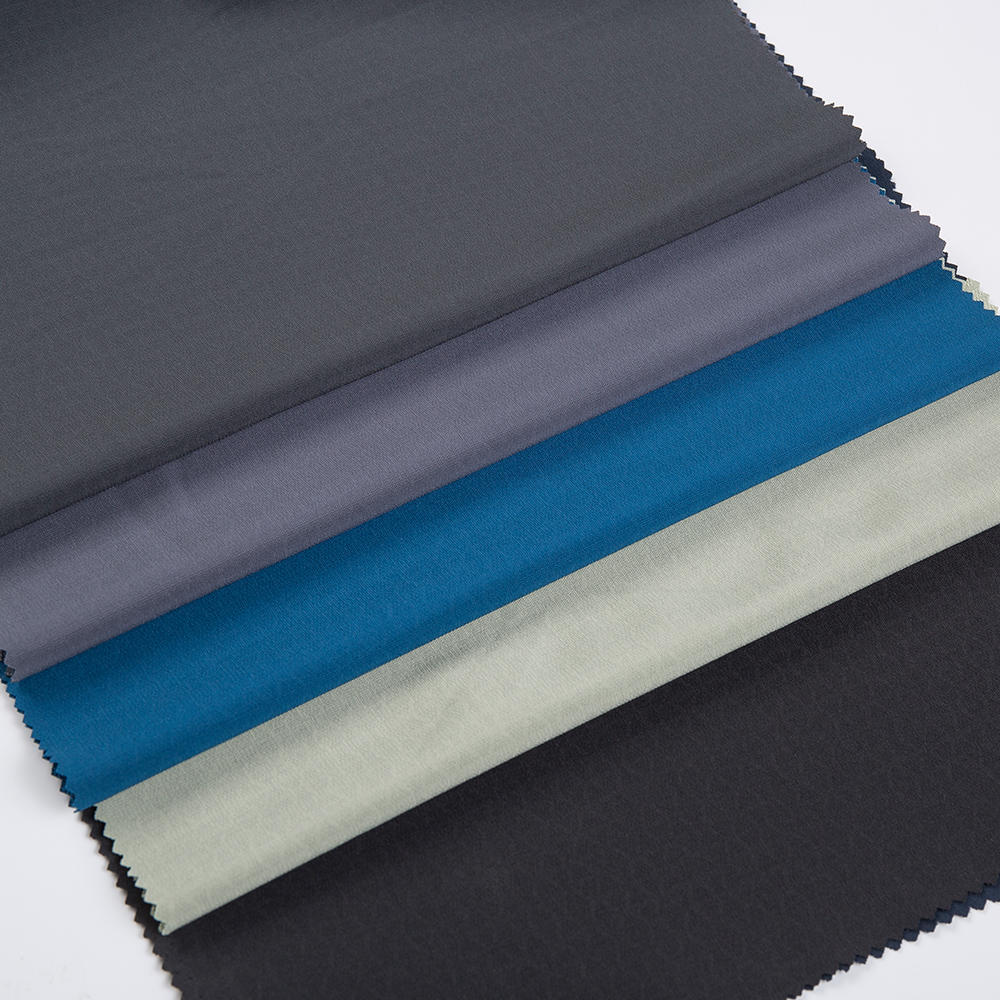

Blending spandex with natural biodegradable fibers is another strategy to reduce microplastic content. Such blends can result in fabrics that release less microplastics after washing.

Furthermore, the development and promotion of sustainable fabric care products such as detergents and fabric softeners that minimize microfiber shedding can contribute to solving the problem.

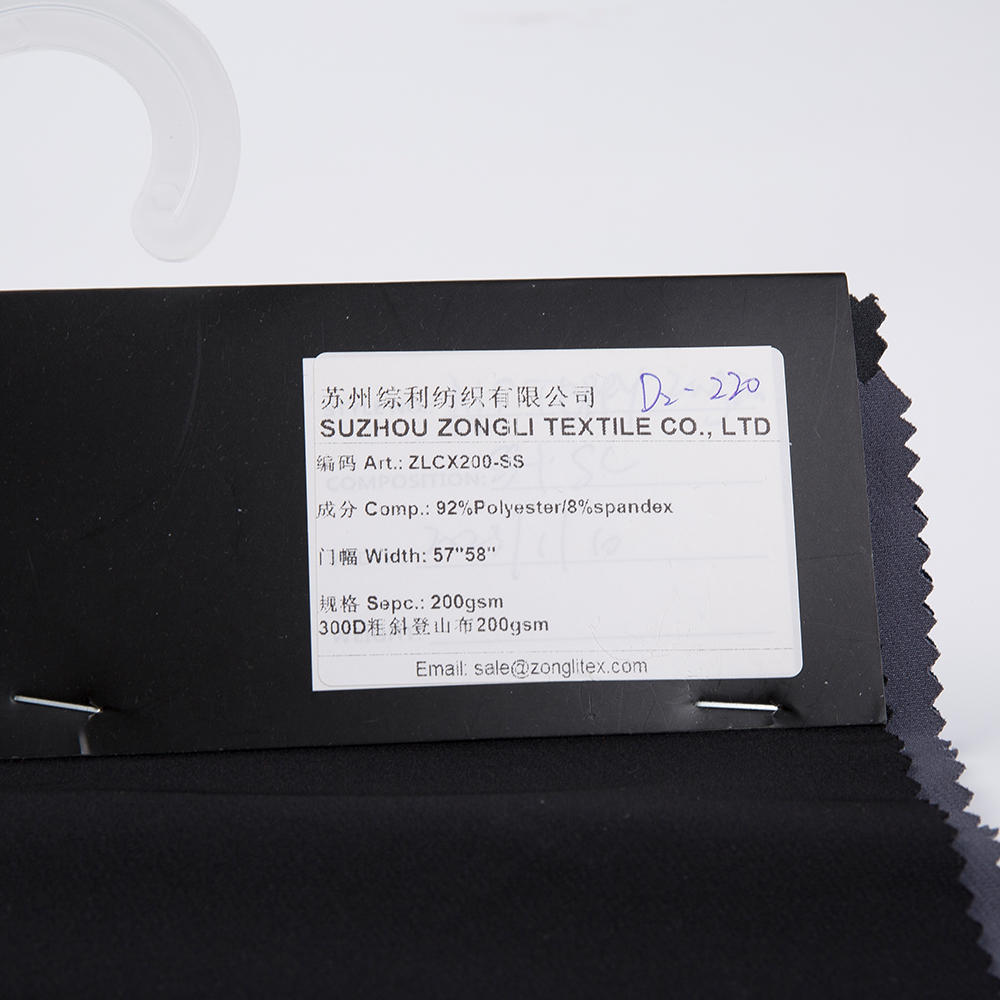

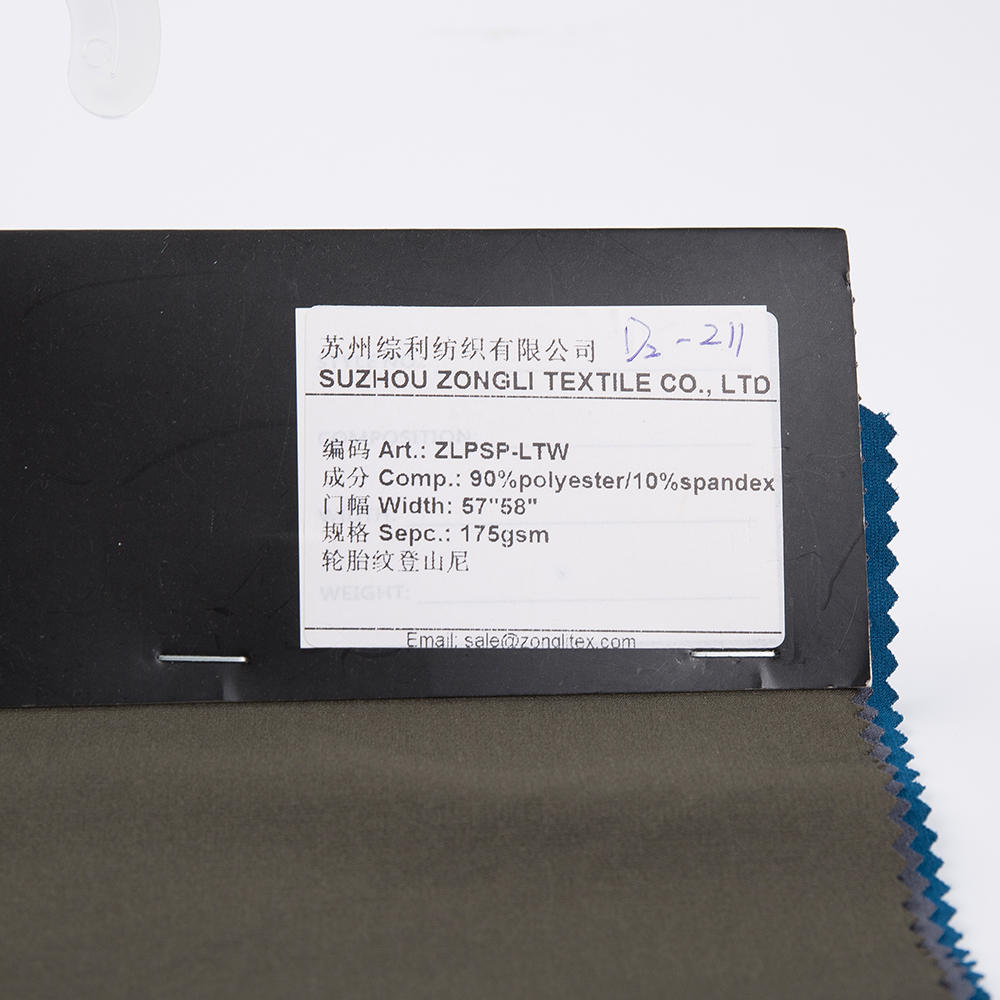

All of these innovative solutions aim to minimize the impact of microplastic pollution from spandex fabrics while maintaining the desired properties and functionality of spandex fabrics. Collaboration between scientists, manufacturers, consumers, and policy makers is essential to effectively address this environmental challenge.For example, a high-quality Spandex fabric Outdoor Jackets can meet the above requirements. If you are looking for an environmentally friendly and pollution-free

Outdoor Jackets Spandex fabric , search carefully and you will find a satisfactory answer.

What are the primary applications and industries where Spandex fabric is commonly used, and how does it contribute to product performance in these applications?

The primary programs and industries in which Spandex fabric is generally used consist of:

Apparel and Fashion Industry: Spandex is appreciably used in the manufacturing of apparel gadgets which include

Outdoor Jackets Spandex fabric, activewear, swimming wear, lingerie, socks, and tights. Its stretchability helps in offering incredible consolation, flexibility, and freedom of movement to the wearer. It additionally helps in maintaining the form and healthy of the garments, preventing sagging or bagging.

Medical and Healthcare: Spandex is applied within the production of compression clothes along with stockings, socks, and sleeves. It provides gentle stress and support, helping in advanced blood circulate, lowering swelling, and preventing deep vein thrombosis. Additionally, it allows for a comfortable fit, ensuring proper guide and alignment during rehabilitation or restoration.

Sports and Outdoor Gear: Spandex is a key component in various sports and outdoor equipment like athletic footwear, gloves, helmets, backpacks, and tents. Its elasticity and durability make contributions to advanced overall performance, consolation, and ease of movement. The stretchiness enables with a proper fit and decreases restrictions, whilst its quick-drying residences enhance breathability and moisture management.

Furniture and Upholstery: Spandex cloth is widely used in the reupholstering of furniture, consisting of chairs, sofas, and vehicle seats. It aids in creating a perfect match, giving a sleek and seamless look, and enhancing the general aesthetics of the furnishings even as preserving durability and strength.

Automotive Industry: Spandex is included into the manufacturing of automobile textiles for seat covers, headliners, and diverse indoors components. Its stretchability facilitates in achieving a cushty fit and retaining form even after prolonged use. Additionally, it complements consolation, presents assist, and improves the sturdiness of the upholstery.

In those applications, Spandex fabric contributes to product overall performance through imparting the following advantages:

Elasticity and Stretch: Spandex's outstanding elasticity permits for garments and merchandise to stretch, recover, and maintain their shape. This enhances comfort, flexibility, freedom of movement, and guarantees a right in shape.

Durability: Spandex cloth reveals awesome resistance to wear and tear. It withstands repetitive stretching and keeps its elasticity over time, contributing to the sturdiness and sturdiness of the goods.

Comfort and Breathability: Spandex has moisture-wicking properties that sell breathability and assist control sweat and warmth. This function is mainly vital in activewear, sports wear, and compression garments, making sure consolation and stepped forward overall performance.

Aesthetics: Spandex cloth aids in creating a swish and seamless appearance. It provides a clean floor, complements the fit and form, and facilitates in shaping and molding various merchandise.

Overall,

Spandex fabric's unique residences make it a versatile material across industries, contributing to greater performance, consolation, sturdiness, and aesthetics.