What is the production process of TPU laminated fabric, and how to ensure production quality?

The production method of TPU laminated material normally entails the subsequent steps:

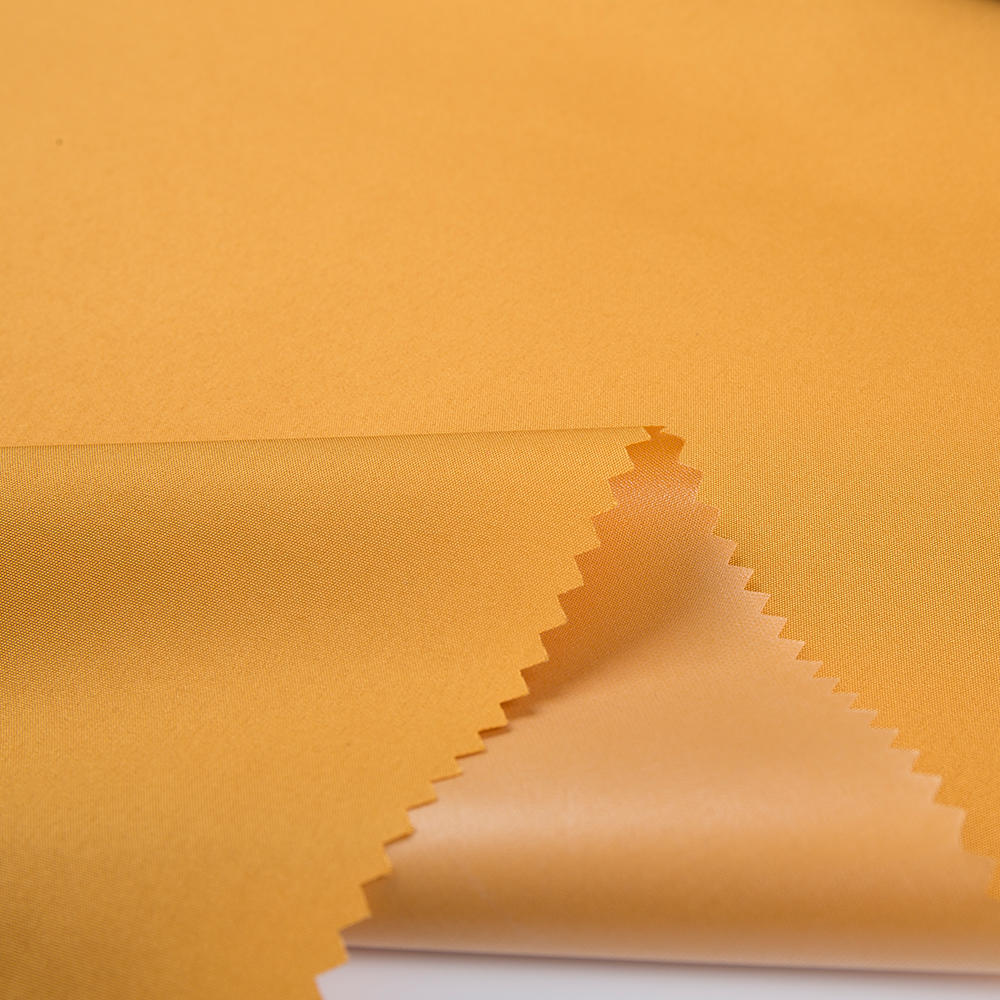

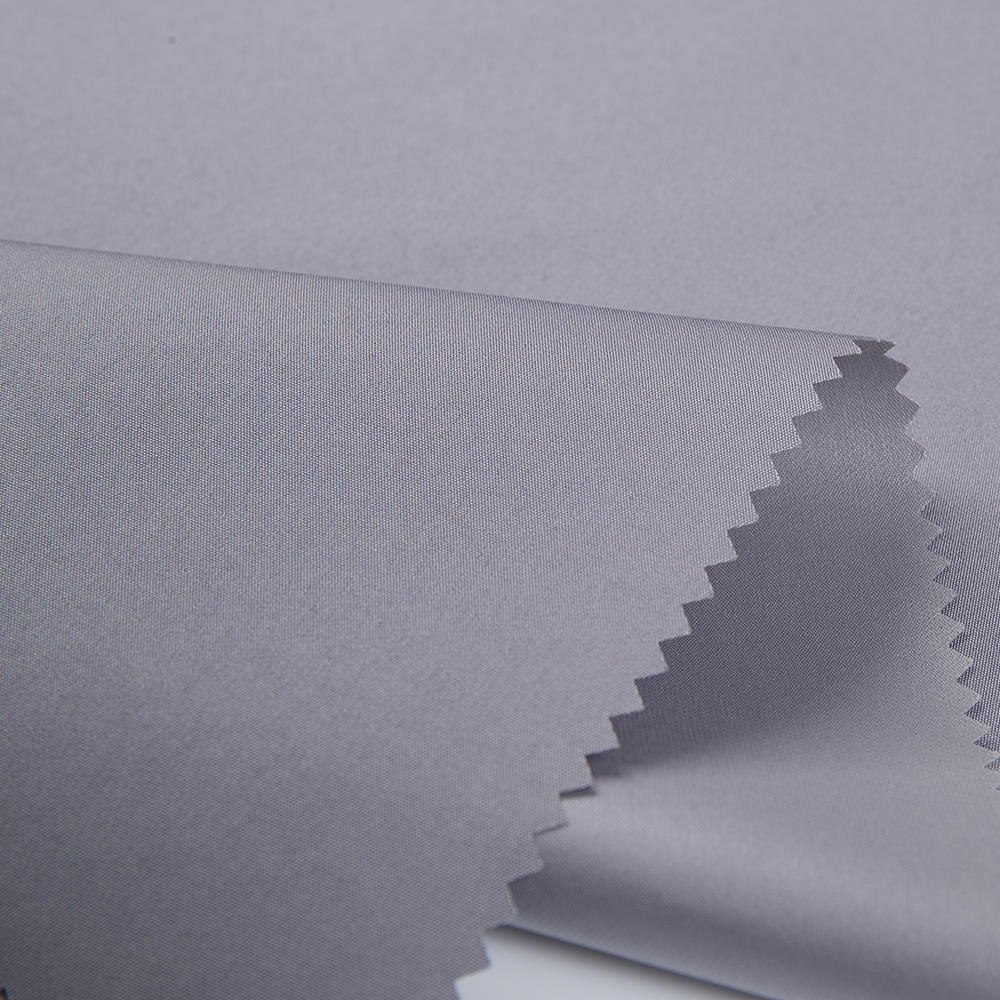

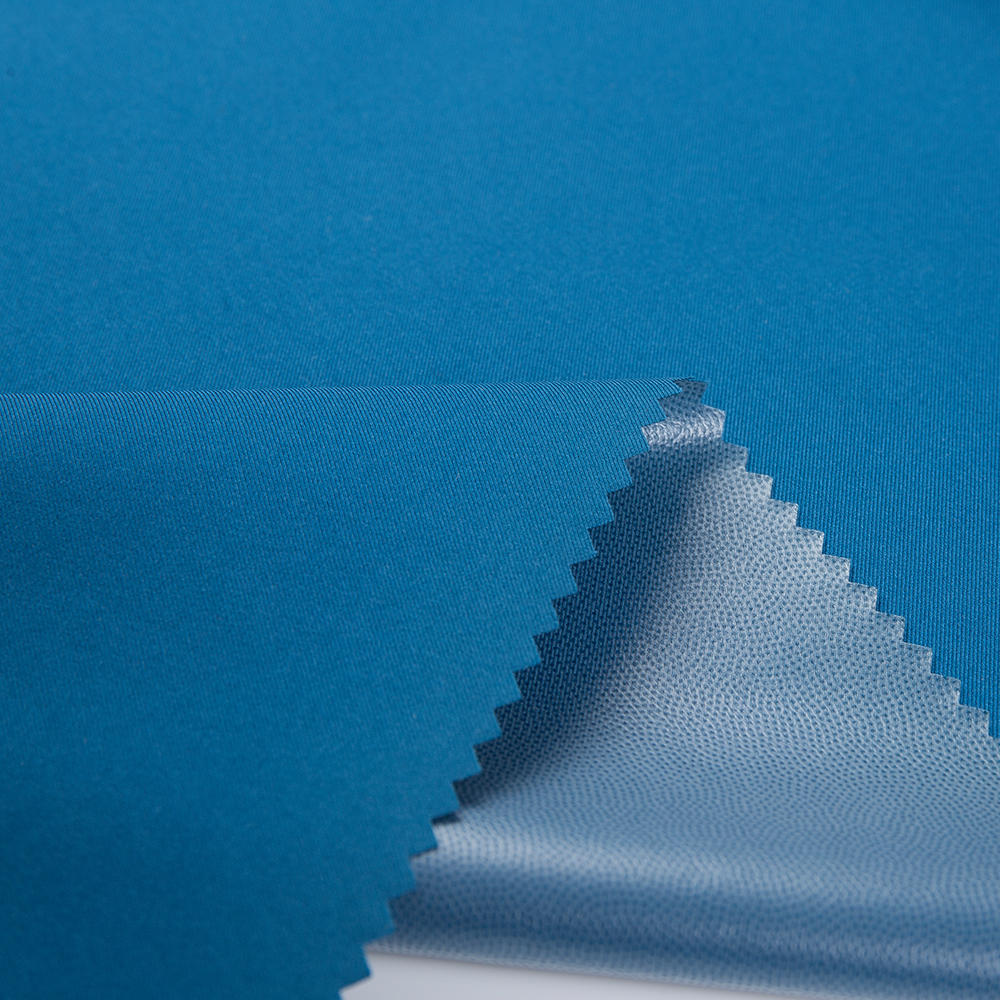

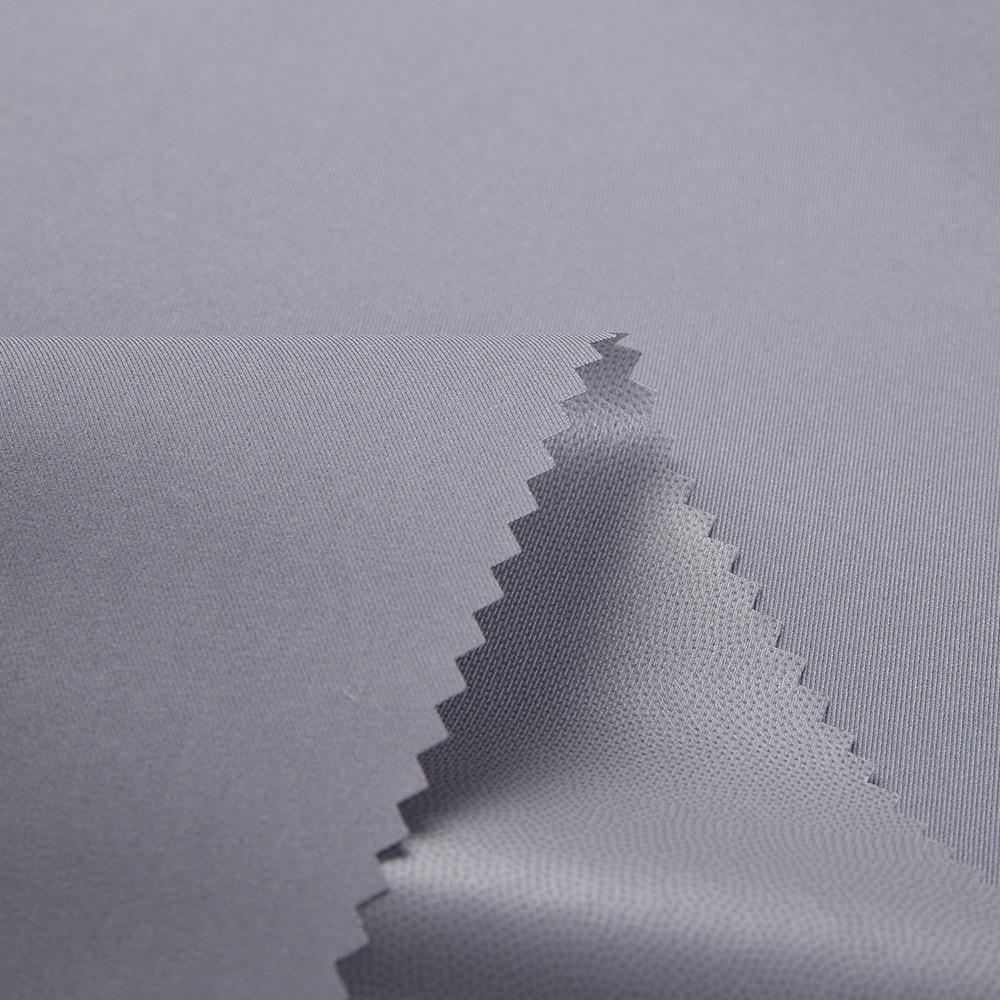

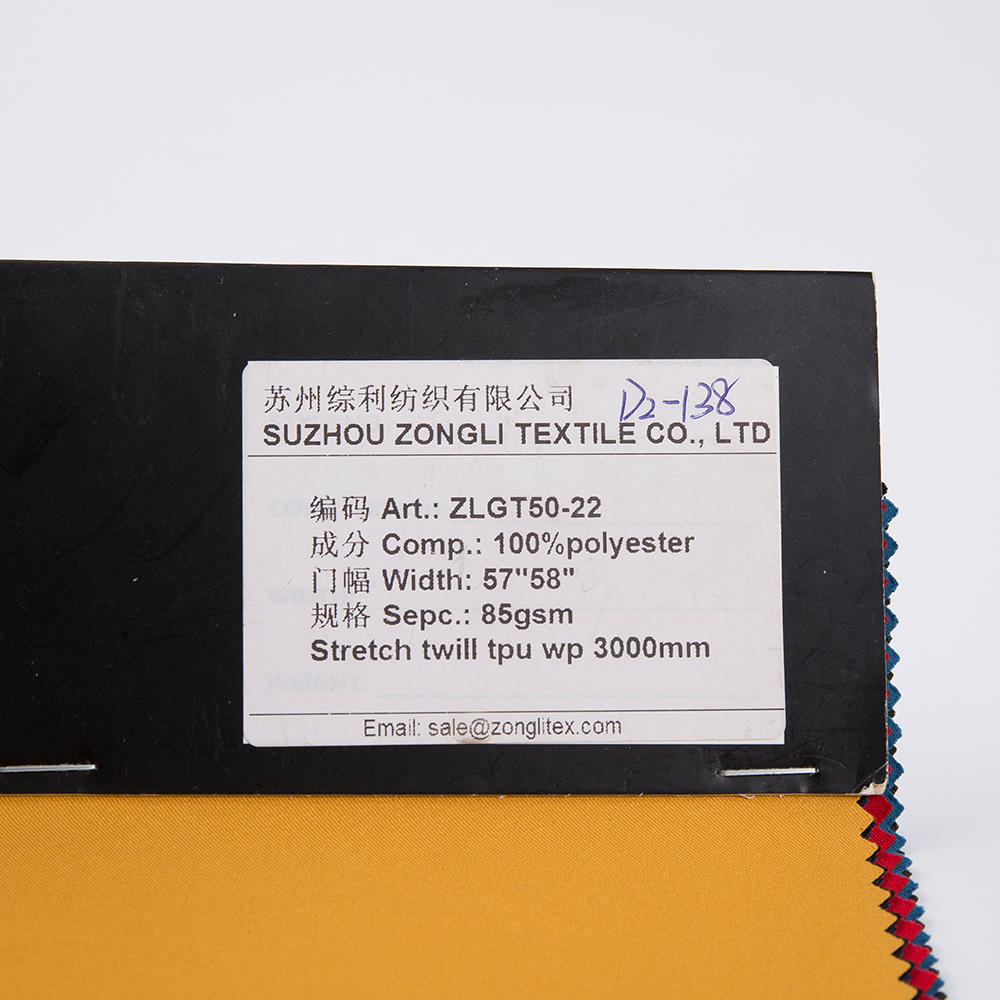

Fabric selection: Choose a suitable base cloth (e.G., polyester, nylon) based totally on the preferred residences and requirements of the stop product.

Preparatory remedies: Before lamination, the bottom fabric is pre-dealt with to ensure cleanliness, put off impurities, and enhance adhesion.

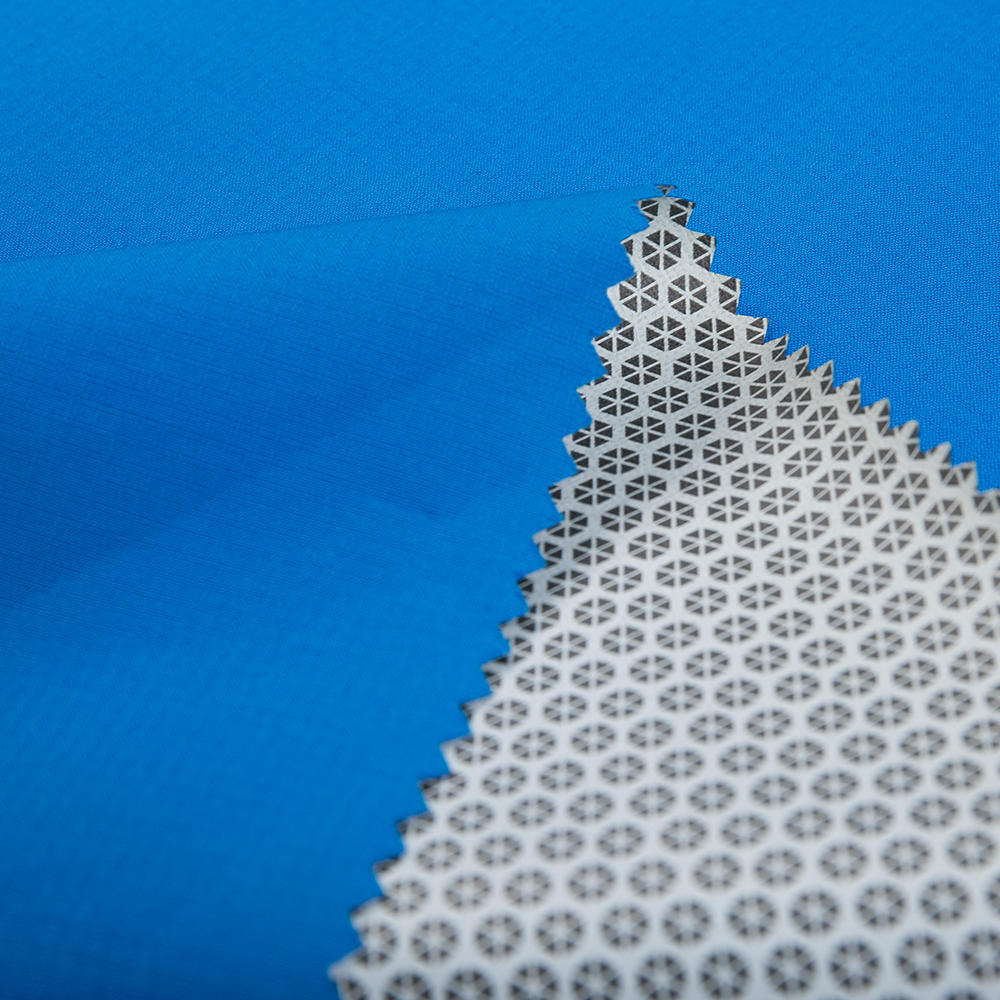

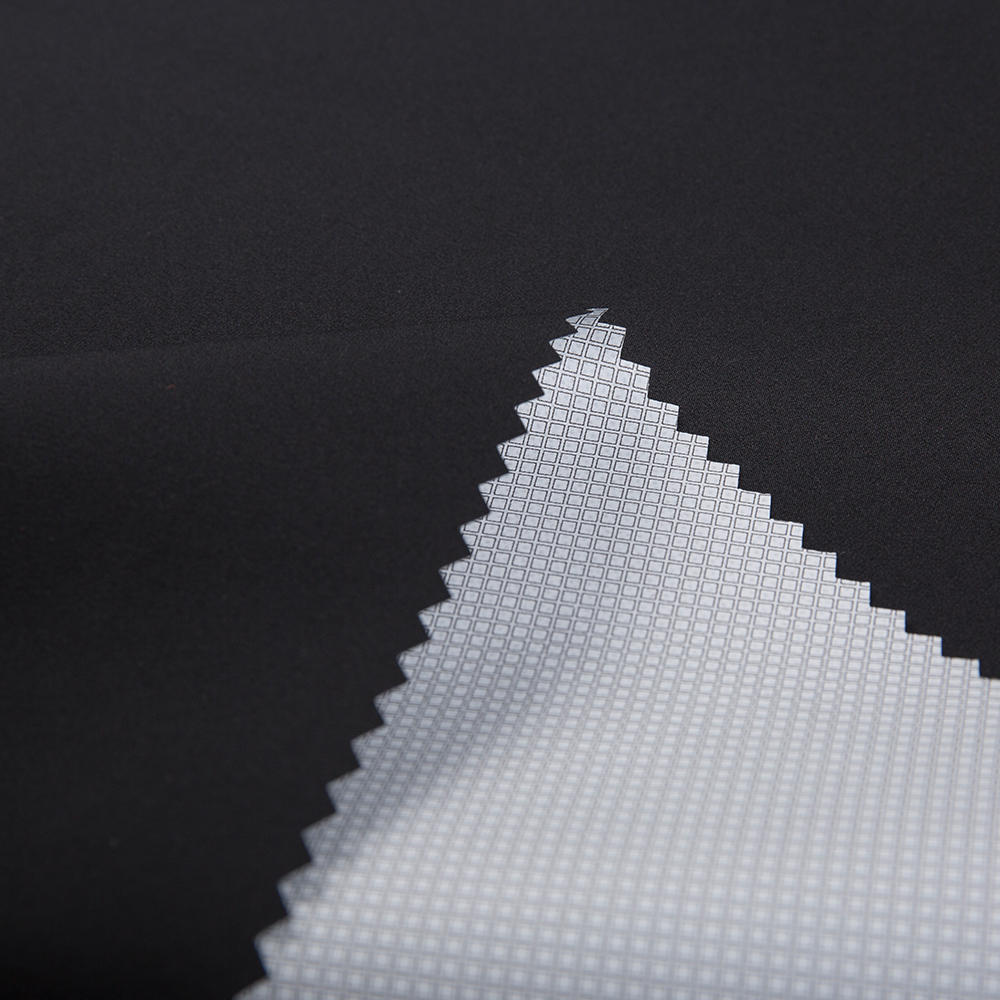

TPU coating: The organized fabric is covered with a thermoplastic polyurethane (TPU) layer the use of diverse techniques which includes direct coating, transfer coating, or warm-melt lamination. This TPU layer gives water resistance, breathability, flexibility, and other preferred characteristics.

Lamination: The covered cloth is then laminated with a launch paper or a temporary provider cloth to shield the TPU layer at some point of the lamination system.

Heat and stress software: The TPU-lined fabric and the discharge paper (or carrier cloth) are exceeded via heated rollers under managed stress. The warmness melts the TPU, which adheres to the base cloth, developing a permanent bond.

Cooling and elimination of release paper: After lamination, the cloth is cooled right down to solidify the TPU layer and make sure right bonding. The release paper (or provider fabric) is eliminated from the TPU layer.

Finishing treatments: The laminated fabric may additionally undergo extra treatments which includes drying, curing, embossing, printing, or other finishing tactics as required by the specific product software.

To ensure production quality, several measures may be taken:

1. Raw cloth selection: Use exquisite TPU and base fabrics from reliable suppliers.

2. Quality manipulate assessments: Implement a robust fine manage gadget at various degrees of the manufacturing system to identify and rectify any problems early on.

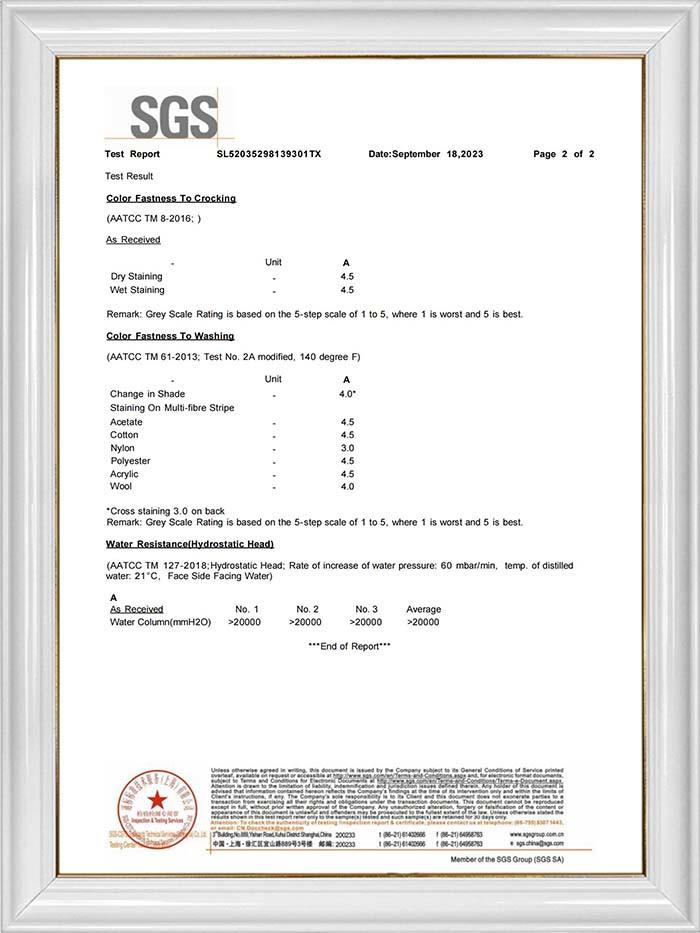

3. Adhesion testing: Regularly check the adhesion power of the TPU layer to ensure proper bonding with the base fabric.

4. Thickness and uniformity manipulate: Monitor and maintain constant TPU coating thickness and uniformity to attain uniform product performance.

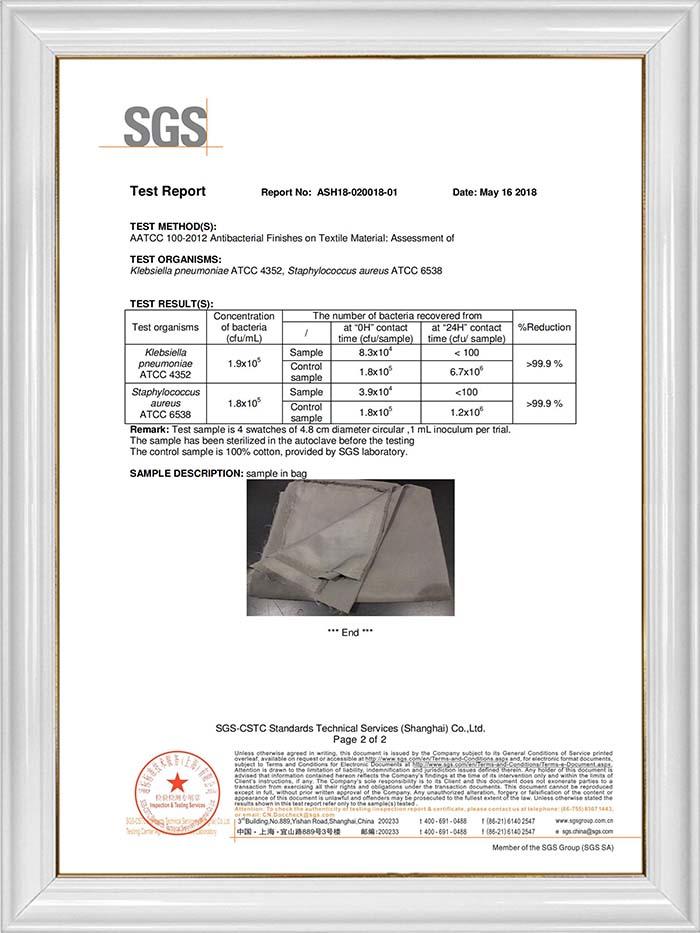

5. Testing for desired homes: Perform tests including water resistance, breathability, tear strength, abrasion resistance, and other relevant characteristics to make certain compliance with required standards.

6. Regular upkeep and calibration: Maintain manufacturing device frequently, calibrate gadgets, and make sure most fulfilling technique situations to avoid deviations in product exceptional.

7. Auditing and high-quality control systems: Adopt diagnosed exceptional control structures (e.G., ISO 9001) and conduct periodic audits to assess and improve the production method.

What are the requirements for the selected TPU for TPU laminated fabric, and how does it affect the final result?

The necessities for the selected TPU (Thermoplastic Polyurethane) for TPU laminated cloth can vary relying on the desired homes of the very last product. Here are a few common requirements and their effect on the final result:

Density and Thickness: The TPU movie ought to have a selected density and thickness to ensure proper adhesion and versatility with the cloth. The density and thickness will affect the general weight and thickness of the laminated material.

Tensile Strength: The TPU ought to have a high tensile strength to offer durability and resistance to ripping or ripping. This property is essential for ensuring the sturdiness and integrity of the very last product.

Abrasion Resistance: The

Outdoor Coats TPU laminated fabric have to have super abrasion resistance to withstand put on and tear from each day use or external factors. This feature is crucial for programs that require a high stage of durability, inclusive of outdoor tools or shielding garb.

Flexibility: The TPU movie ought to have enough flexibility to allow the cloth to hold its supposed drapability and movement. This flexibility ensures that the laminated material keeps its authentic experience and is cushty to put on or use.

Water Resistance: TPU offers water-proof houses, which may be suitable for positive programs like rainwear or sports clothing. The decided on TPU have to offer the desired stage of water resistance to shield the fabric and the wearer from moisture.

Breathability: Depending at the utility, it is able to be critical to preserve breathability of the laminated material. The chosen TPU ought to permit suitable moisture vapor transmission to prevent a build-up of perspiration or soreness whilst utilized in activities that contain expanded physical exertion.

Transparency and Clarity: In a few cases, TPU laminated material can also require transparency or clarity, consisting of in scientific or business applications. The decided on TPU movie ought to provide the favored degree of transparency or clarity, with out compromising other performance traits.

These necessities for the chosen TPU will immediately effect the final end result of the TPU laminated cloth, determining its energy, durability, flexibility, water resistance, breathability, and universal look. By selecting the suitable TPU movie, producers can make certain that the final product meets the preferred specs and plays successfully in its supposed utility.