What measures are taken to prevent coated fabric from cracking?

There are numerous measures that may be taken to prevent lined cloth from cracking:

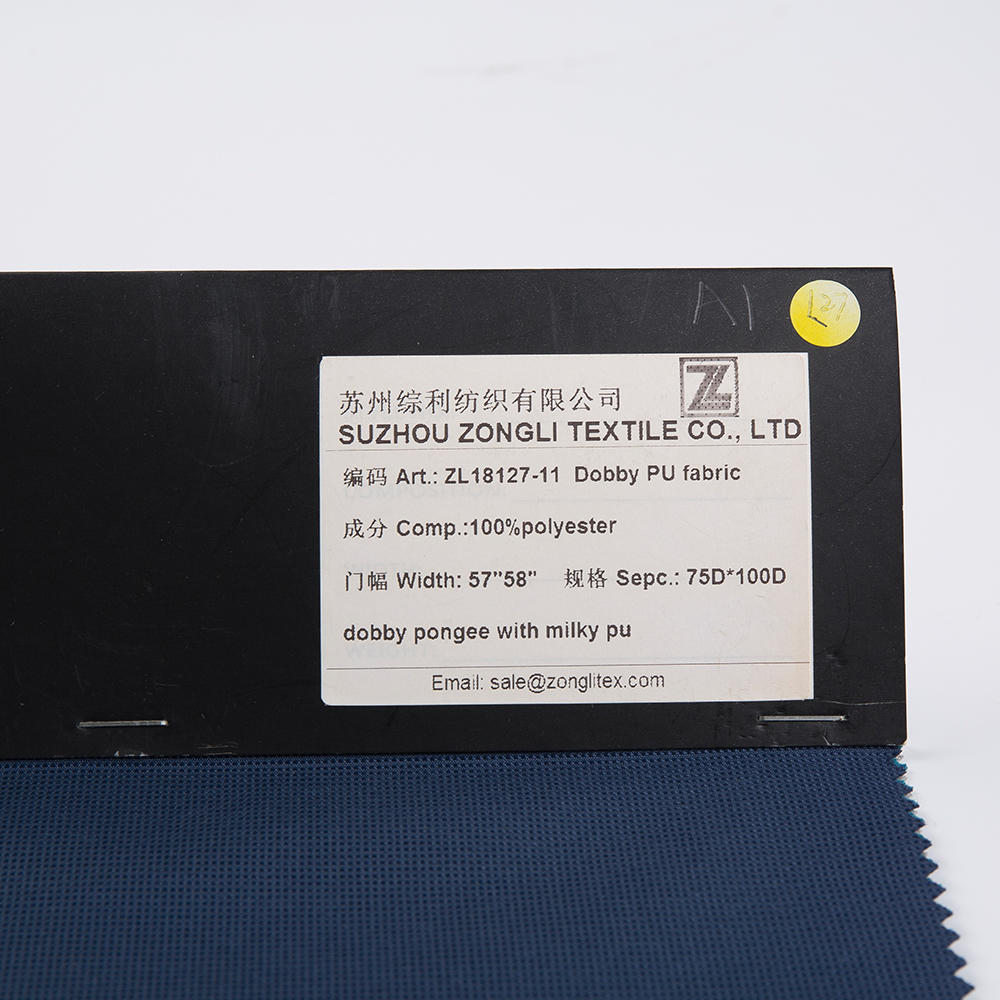

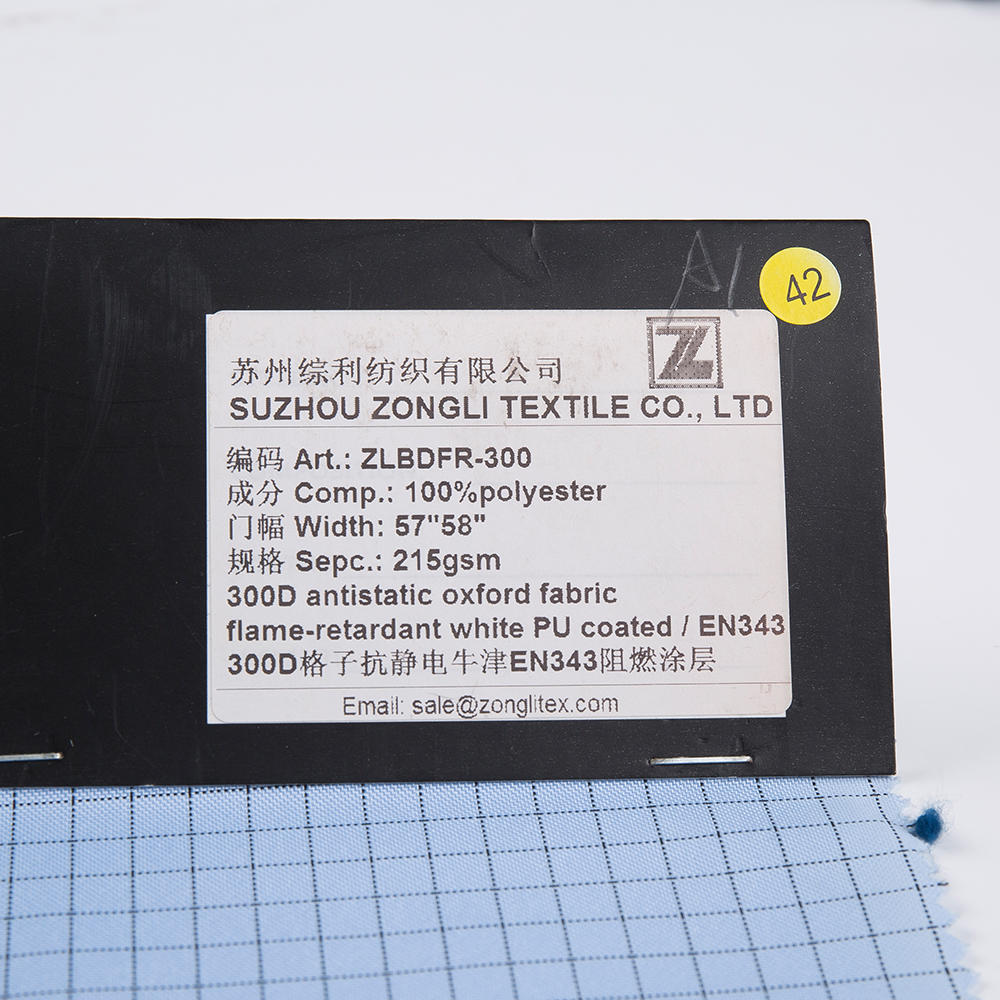

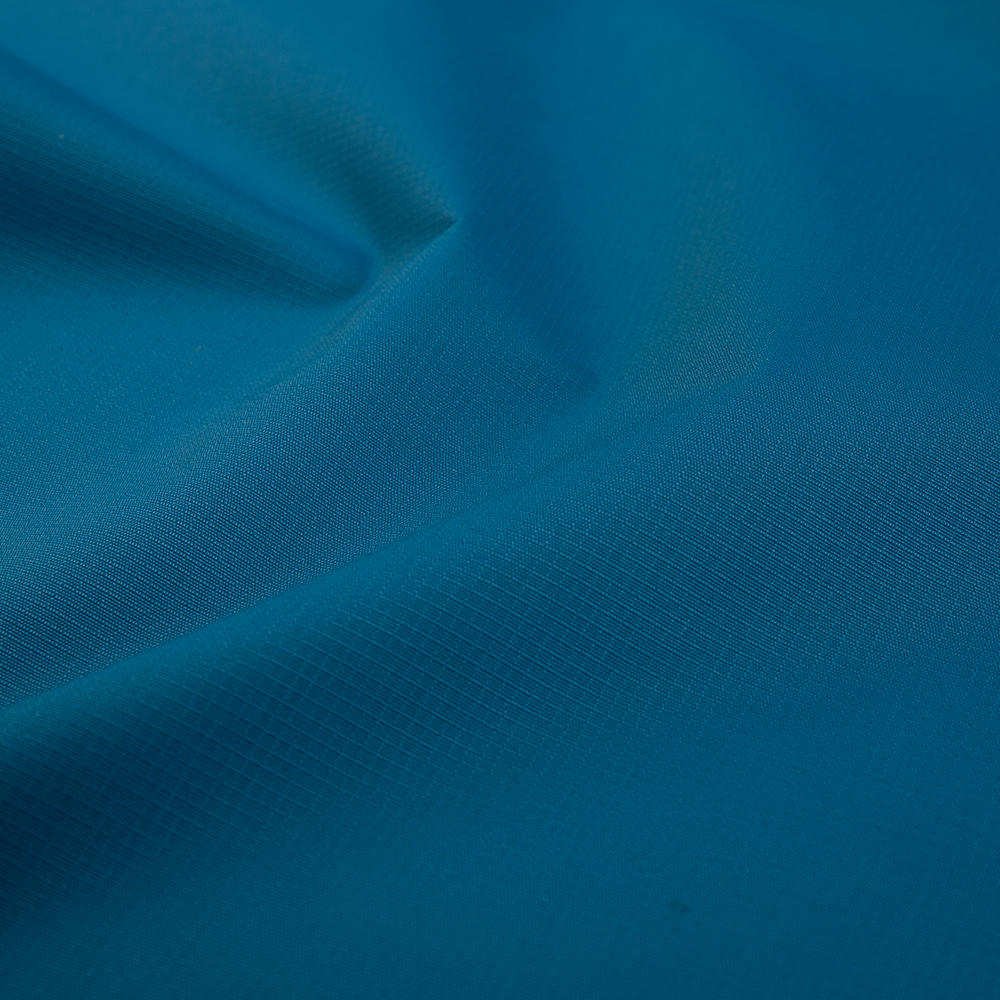

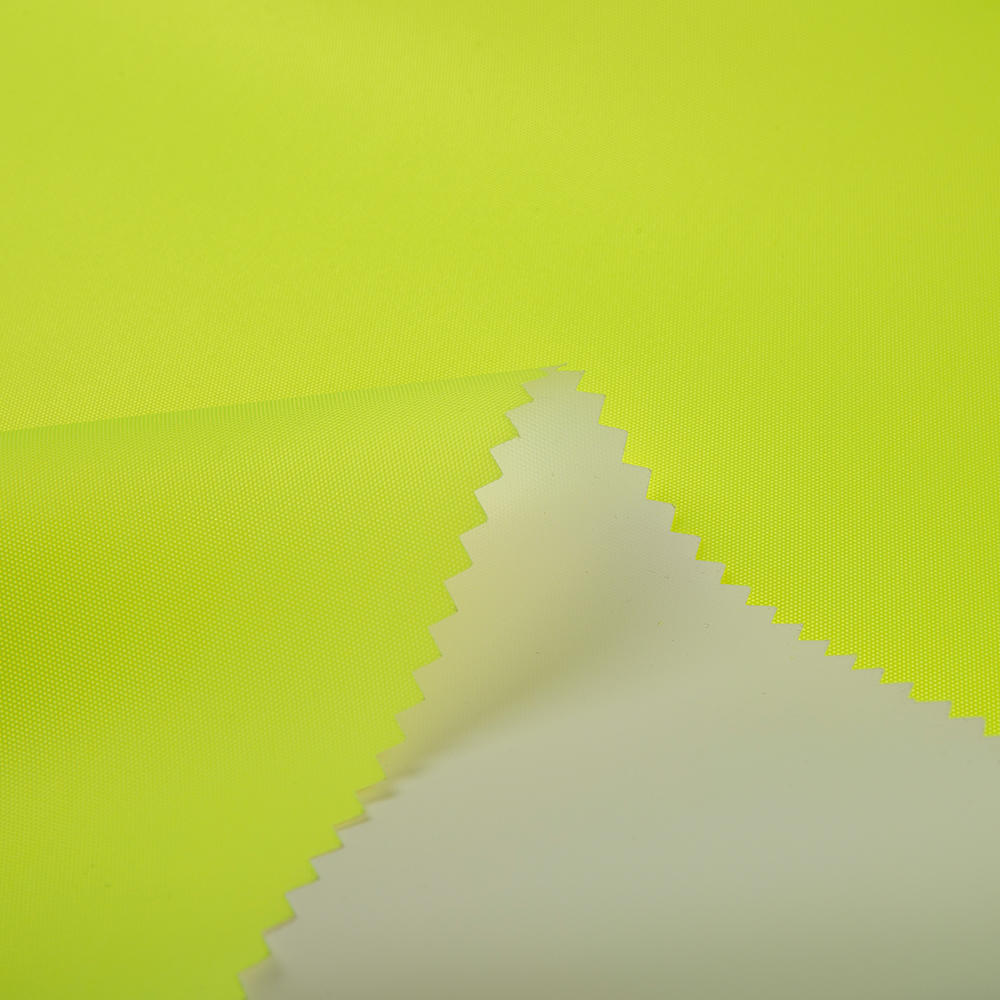

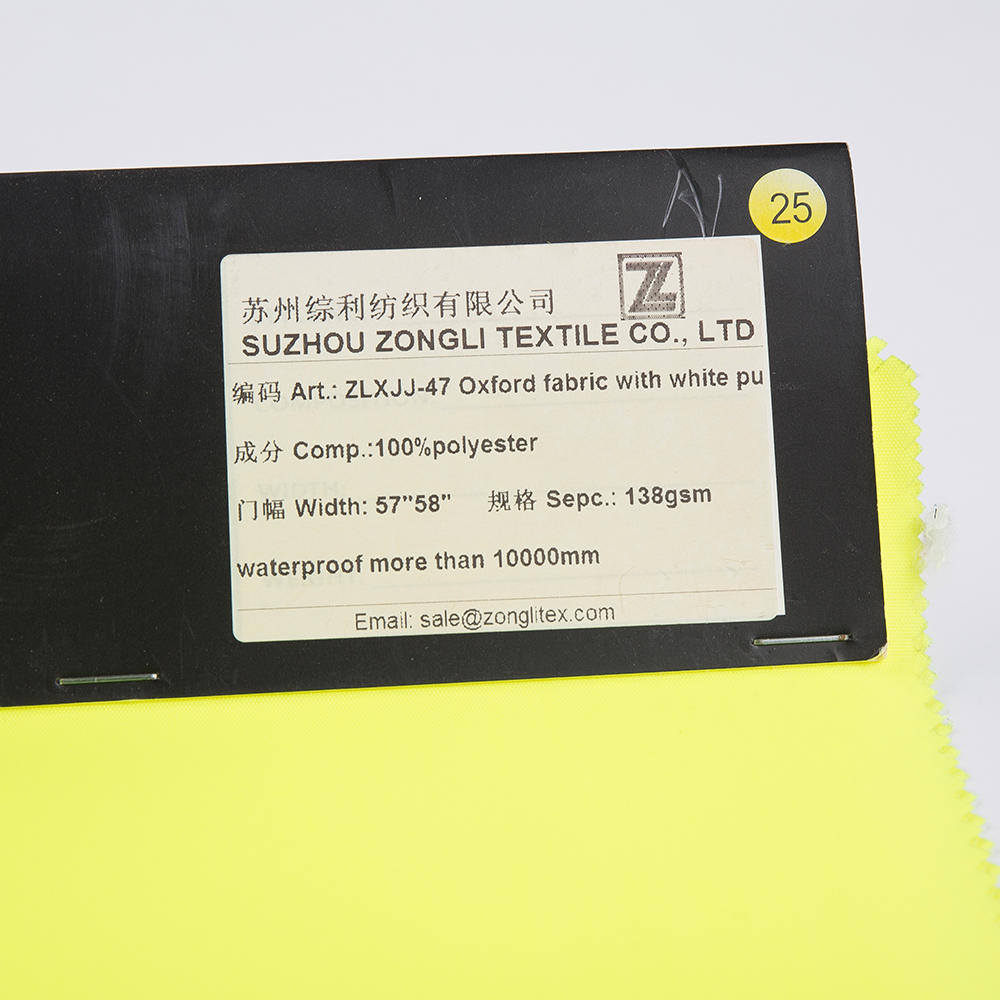

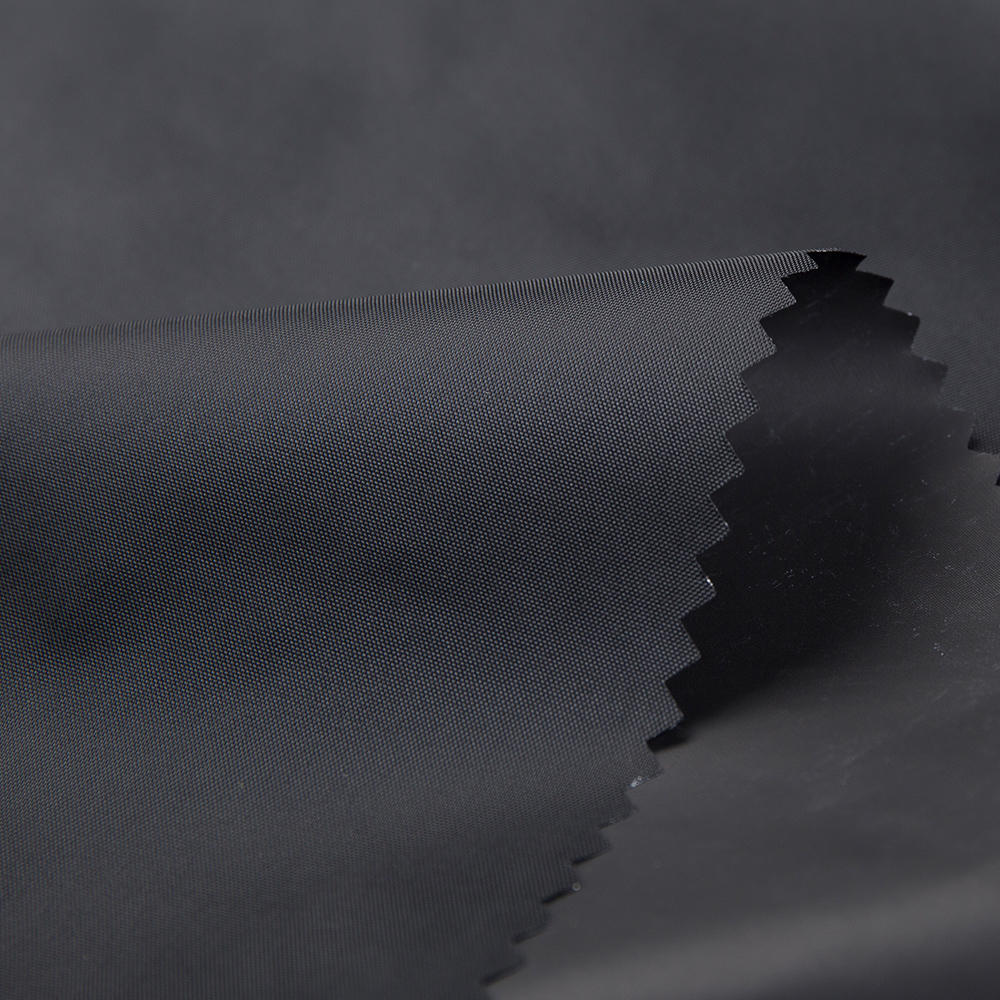

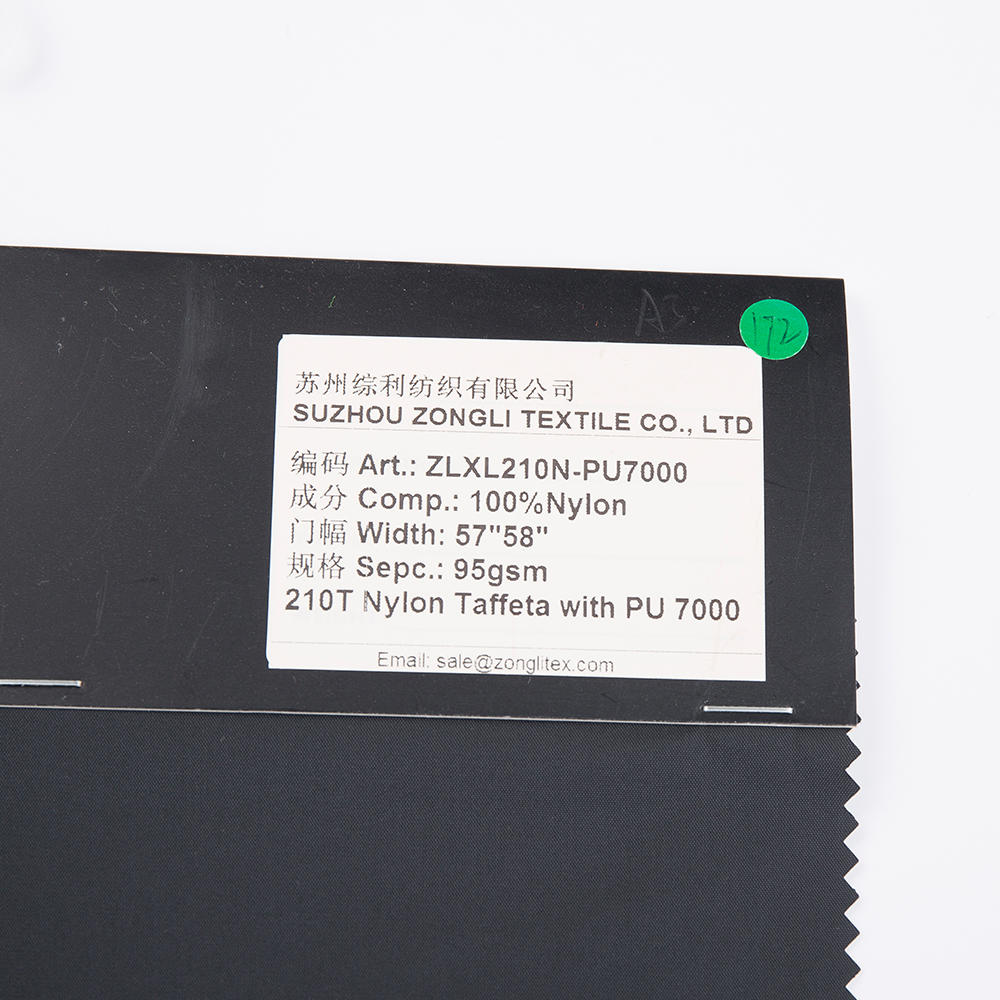

Selection of incredible materials: It is crucial to pick out terrific fabrics and coating materials that have proper flexibility and resistance to cracking. Using long lasting and flexible substances can assist prevent cracking.

Proper curing and drying method: Coated fabric want to undergo a right curing and drying method to ensure that the coating is fully bonded to the material. This procedure enables the coating to set nicely and complements its flexibility, lowering the possibilities of cracking.

Application of appropriate thickness: The coating thickness should be consistent and appropriate. An overly thick coating may be extra susceptible to cracking, at the same time as a skinny coating won't offer enough protection. Proper software of the coating guarantees a fair distribution and thickness, reducing the chance of cracking.

Flexibility components: Adding flexibility additives to the coating components can assist boom the ability and elasticity of the coating, minimizing the probabilities of cracking. These additives beautify the coating's capacity to face up to stretching and bending with out cracking.

Maintenance and care: Proper upkeep and care of the coated fabric also can save you cracking. This includes avoiding hot temperature modifications, immoderate stretching, and publicity to harsh chemical substances or solvents, as these can become worse the coating and growth the risk of cracking.

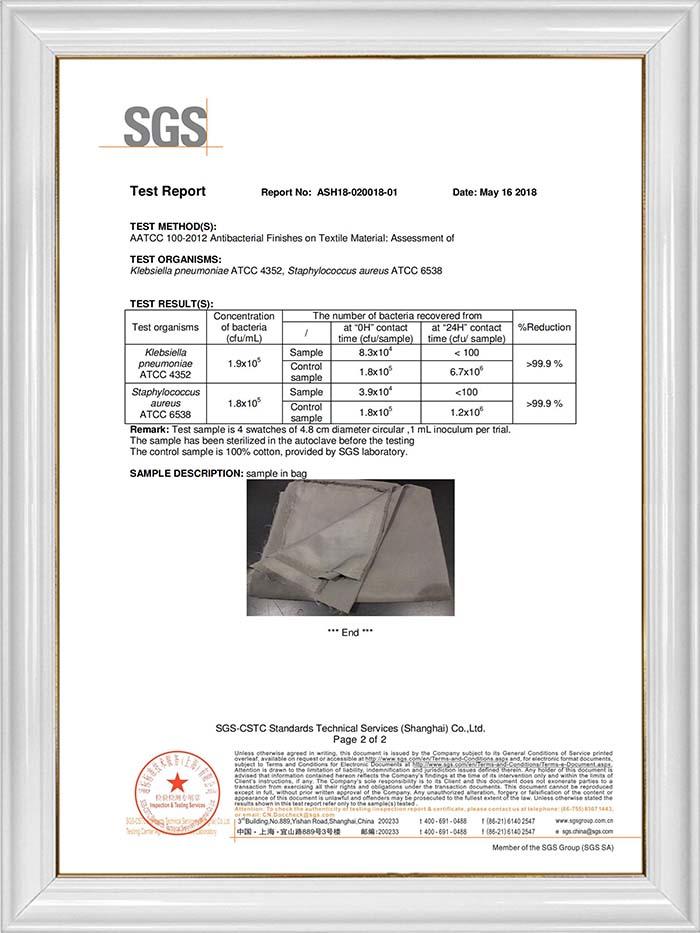

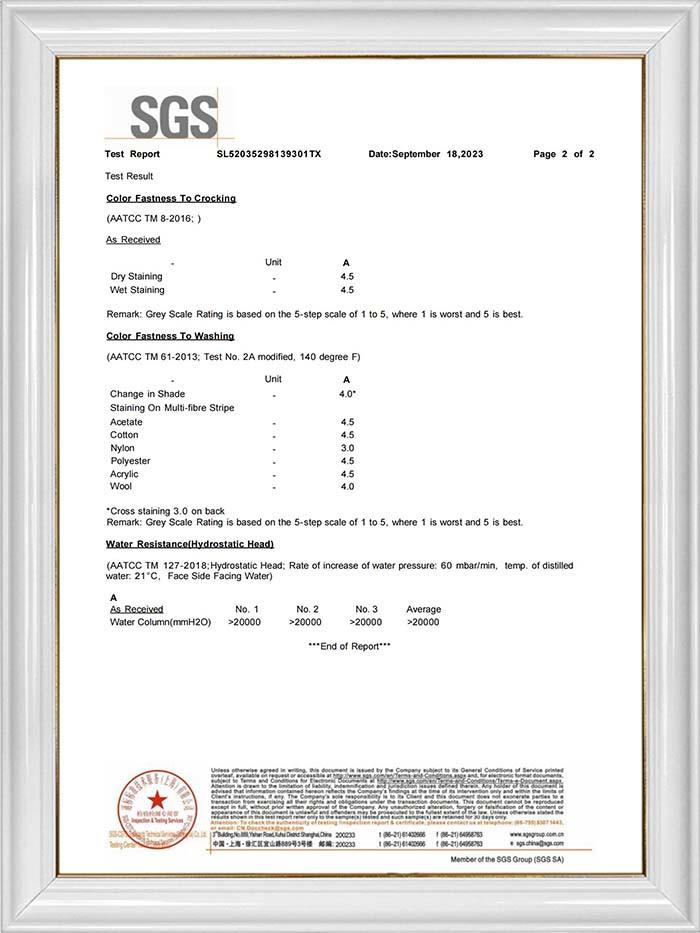

Quality control and checking out: Regular quality manipulate exams and testing can assist discover any potential problems with the

Outdoor Jacket coated fabric 's, consisting of insufficient flexibility or untimely cracking. This allows manufacturers to make essential adjustments and upgrades within the manufacturing process.

How to ensure that the coating of coated fabric is fully bonded to the material during the production process?

To ensure that the coating of

coated fabric is fully bonded to the material during the production process, you can follow these steps:

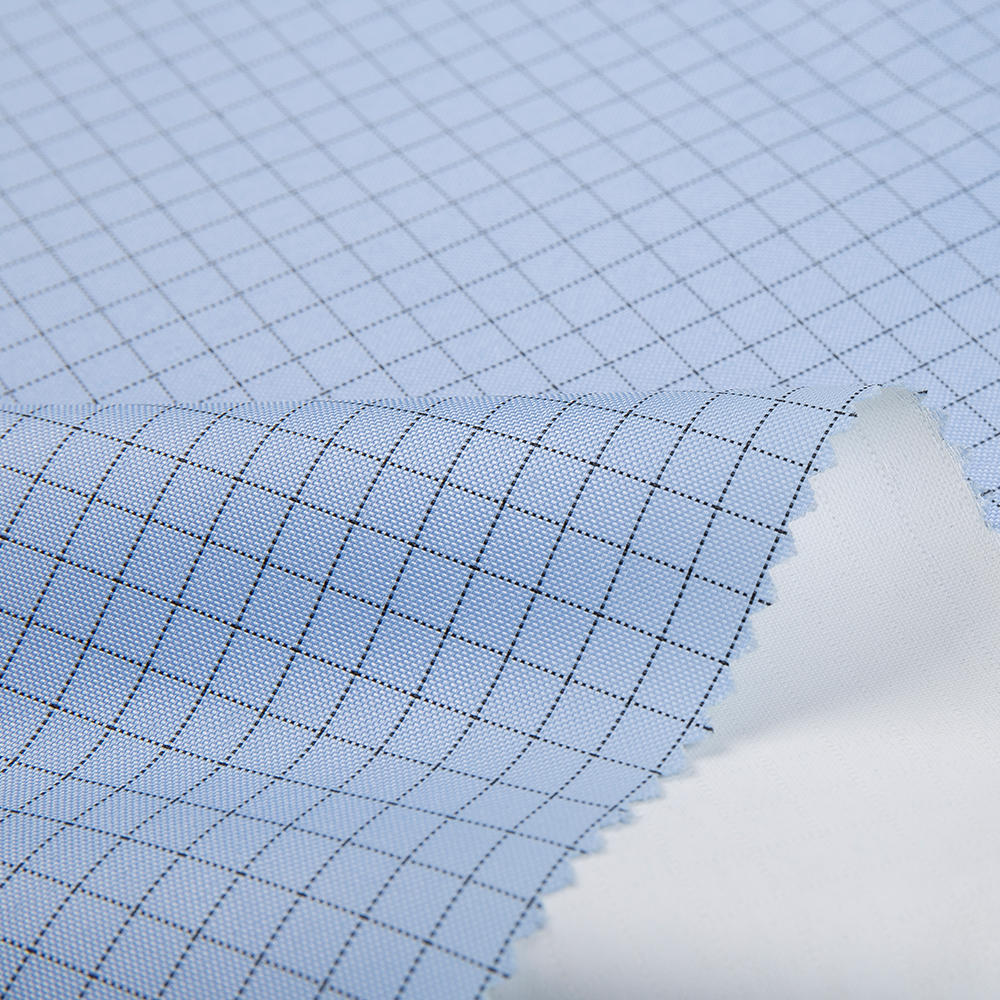

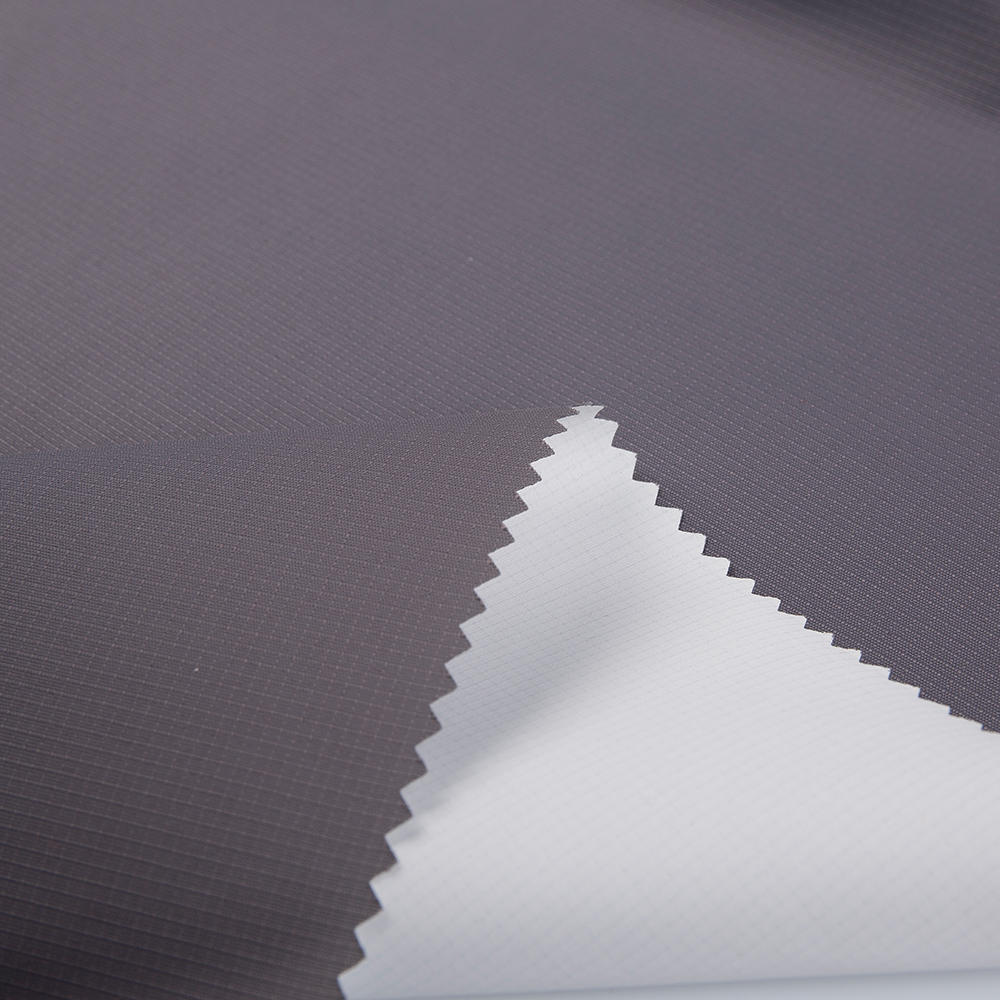

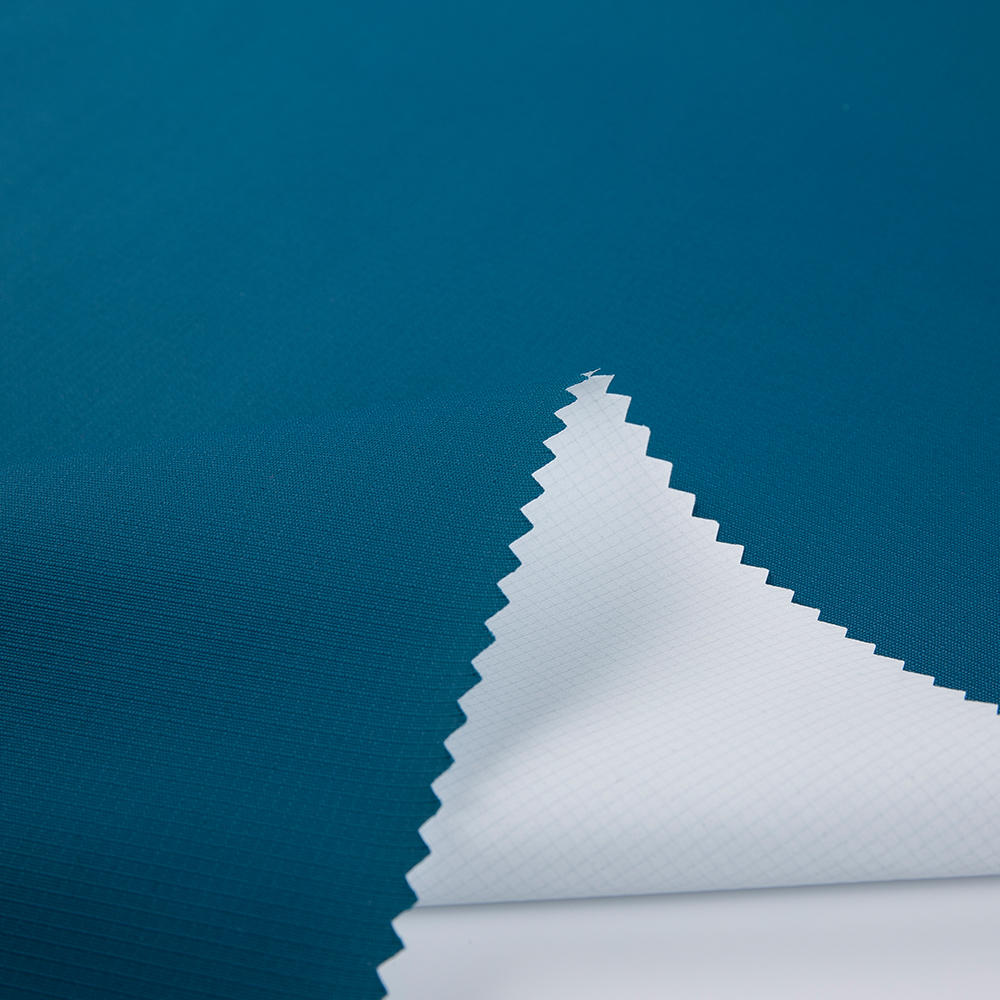

Surface Preparation: Properly prepare the fabric surface to ensure good adhesion. Remove any dirt, dust, or contaminants from the fabric surface using appropriate cleaning methods.

Proper Coating Application: Pay attention to the coating application process to ensure uniform coverage. Use the recommended tools, such as brushes, rollers, or sprayers, and apply the coating evenly over the entire fabric surface.

Follow Manufacturer Guidelines: Always refer to the manufacturer's guidelines and instructions for the specific coating material being used. Manufacturers often provide specific instructions regarding optimal application methods, drying times, and temperature requirements.

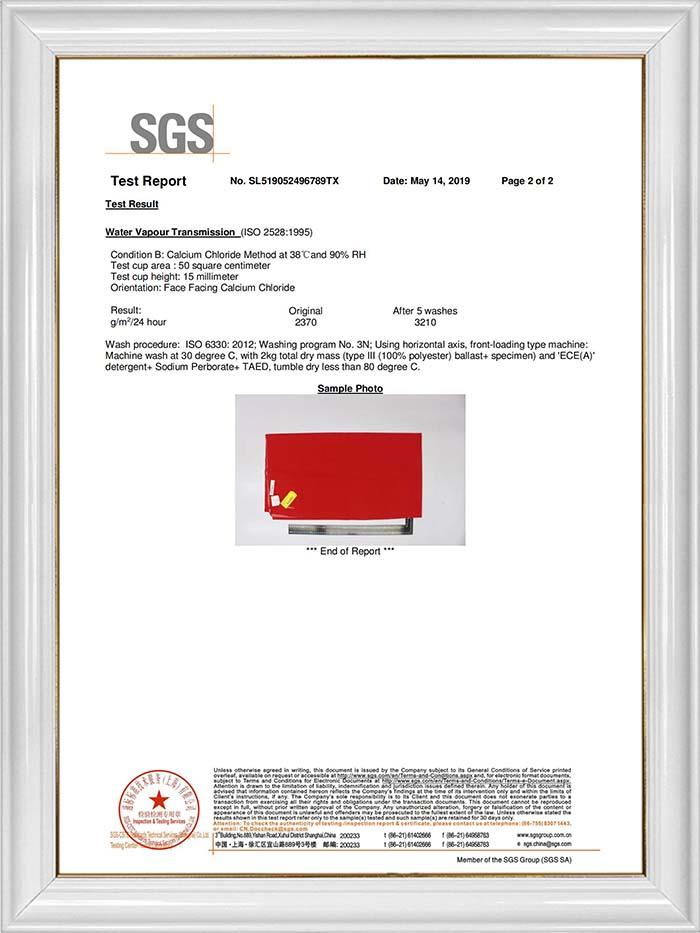

Adequate Drying/Curing Time: Allow sufficient time for the coating to dry or cure. Follow the recommended drying/curing time specified by the manufacturer. Proper drying ensures that the coating adheres firmly to the fabric and prevents it from peeling off or weakening over time.

Heat Activation (if applicable): Some

Outdoor Jacket coated fabric may require heat activation to enhance the bonding process. If instructed by the manufacturer, heat the coated fabric to the specified temperature for a recommended duration. This process helps in achieving a stronger bond between the coating and the fabric.

Quality Control Checks: Implement a quality control process to inspect the coated fabric after production. Ensure that the coating is evenly bonded to the fabric and there are no defects, bubbles, or areas of poor adhesion. Conduct rigorous testing to confirm the coating's durability, flexibility, and resistance to environmental factors.

Post-Coating Treatments: Certain additional treatments like topcoats or finishing agents may be required. Follow the recommendations provided by the manufacturer for any post-coating treatments to further enhance the bond between the coating and the fabric.