How does the thickness and composition of the PVC coating affect the fabric's resistance to environmental factors, such as water, UV radiation, and chemicals?

The thickness and composition of the PVC coating on material will have vast consequences on its resistance to environmental factors, together with water, UV radiation, and chemical compounds. Here are the general affects:

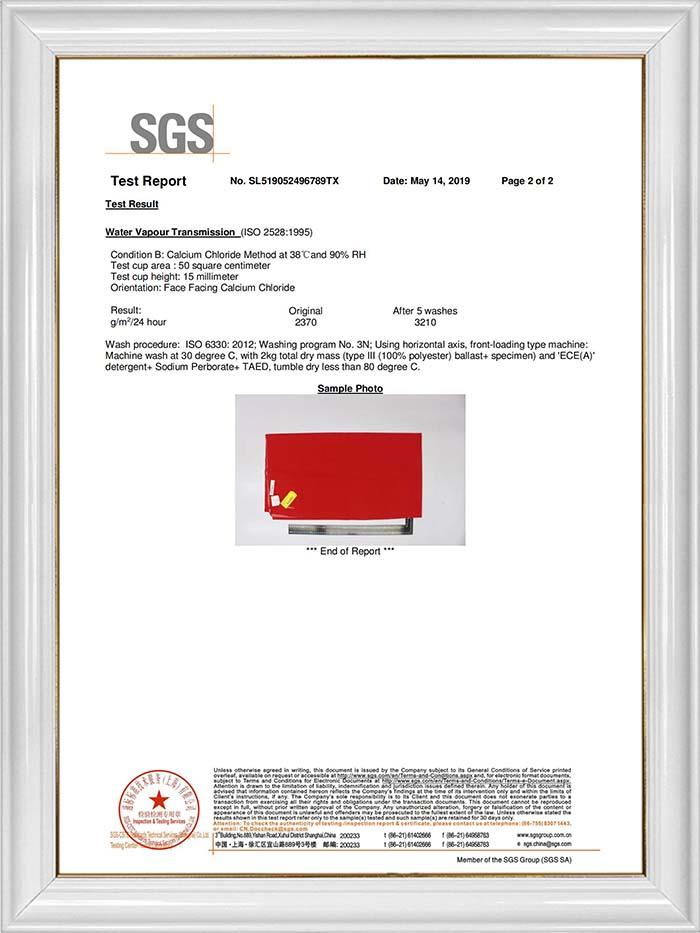

Water Resistance: A thicker

PVC coated fabric typically provides better water resistance, as it creates a bodily barrier that stops water from penetrating the cloth surface. Additionally, a tightly knit or densely woven material with a PVC coating can enhance water resistance. The composition of the PVC coating can have an effect on the hydrophobic homes, with a few formulations being inherently extra water repellent.

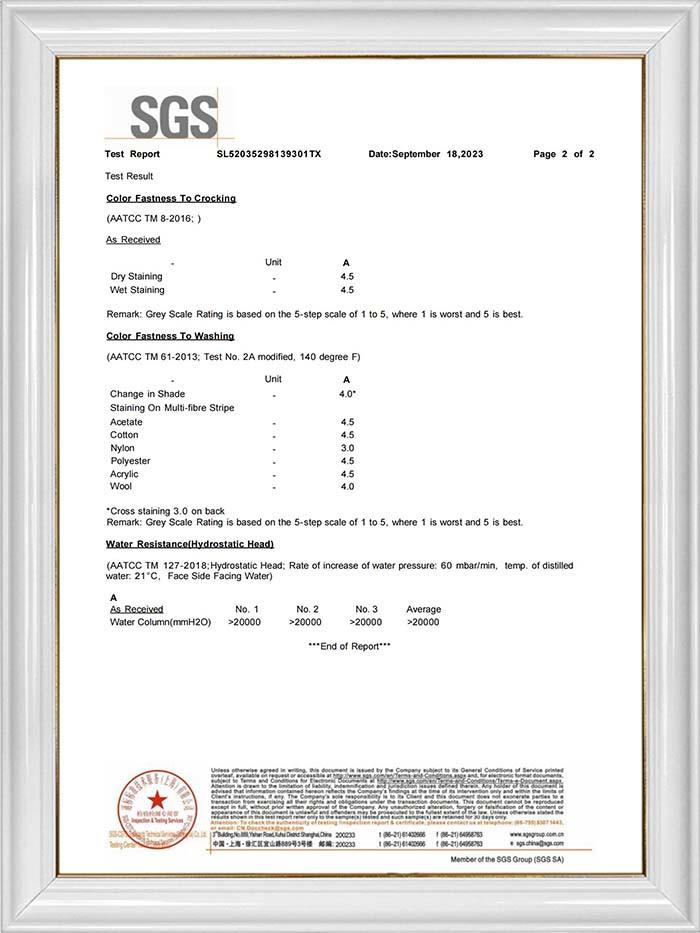

UV Resistance: PVC coatings can provide first rate protection against UV radiation. The thickness of the coating is crucial in blocking harmful UV rays from reaching the fabric. A thicker PVC coating can save you UV radiation from degrading the underlying fabric and reduce colour fading. Additionally, a few PVC formulations include UV stabilizers, which decorate the cloth's resistance to UV damage.

Chemical Resistance: The composition of the

Outdoor Jackets PVC coated fabric performs a essential position in figuring out its resistance to chemical compounds. PVC coatings may be customized with diverse additives to face up to chemical degradation or damage from specific substances. Thicker coatings typically offer better protection towards chemical exposure, as they devise a thicker barrier between the fabric and the chemicals. However, the specific chemical resistance also can depend on the kind of PVC components used.

It is vital to notice that at the same time as PVC coatings can enhance the fabric's resistance to those environmental factors, the overall durability and overall performance can also be inspired with the aid of the best of the underlying fabric and the construction strategies used.

How to print on PVC coated fabric and keep it bright and lasting?

To achieve a bright and lasting print on PVC coated fabric, you should consider the following points:

Select a high-quality PVC coated fabric: Choose a fabric that is specifically designed for printing purposes. Look for a fabric that is strong, durable, and has a smooth surface to ensure optimal printing results. Consider PVC coated fabrics that are specifically made for outdoor use, as they are more resistant to fading and harsh weather conditions.

Prepare the fabric surface: Before printing, it is essential to ensure that the fabric surface is clean and free from any dirt, debris, or oils. Use a mild detergent and water to gently clean the fabric, and then thoroughly rinse and dry it. This step will allow the ink to adhere better to the fabric and prevent any interference that might affect the print quality or longevity.

Use compatible printing inks:

Outdoor Jackets PVC coated fabric require printing inks that are specially formulated for this type of material. Make sure to use inks that are designed for outdoor applications, as they are typically more fade-resistant and have better adhesion properties. Consult with the ink manufacturer or supplier to select the appropriate ink type for your specific PVC coated fabric.

Opt for dye-sublimation printing: Dye-sublimation printing is an excellent method for printing on PVC coated fabric. This process involves the use of heat to transfer colored inks directly into the fabric, resulting in vibrant and long-lasting prints. Dye-sublimation printing offers excellent color reproduction, durability, and resistance to fading, making it a popular choice for graphics and designs on PVC coated fabrics.

Ensure proper curing and heat-setting: Once the printing is complete, it is crucial to properly cure or heat-set the ink to ensure its durability and longevity. Follow the manufacturer's instructions regarding heat and time settings to achieve optimum curing. This process will allow the ink to bond with the fabric permanently, making it more resistant to fading, abrasion, and washing.

Consider adding a protective coating: To further enhance the durability and longevity of the print, you may consider applying a protective coating or laminate to the PVC coated fabric. These coatings provide an additional layer of protection against UV rays, moisture, abrasion, and other environmental factors that could potentially degrade the print quality. Consult with a professional or the coating manufacturer for the most suitable coating option for your specific application.

Proper maintenance and care: To ensure the print's brightness and longevity, it is essential to maintain and care for the PVC coated fabric correctly. Avoid using harsh cleaning agents or solvents that might damage the print. Regularly clean the fabric using mild detergents and a soft cloth or sponge. Additionally, avoid prolonged exposure to direct sunlight or extreme weather conditions, as these factors can deteriorate the print over time.

By carefully considering and implementing these points, you can achieve bright and lasting prints on PVC coated fabric that will maintain their quality and vibrancy over an extended period, even in outdoor or high-traffic environments.