What are the key properties that define Mechanical stretch fabric, and how does it differ from other stretch fabrics?

Mechanical stretch fabric, also known as two-way stretch fabric, has several key properties that differentiate it from other stretch fabrics:

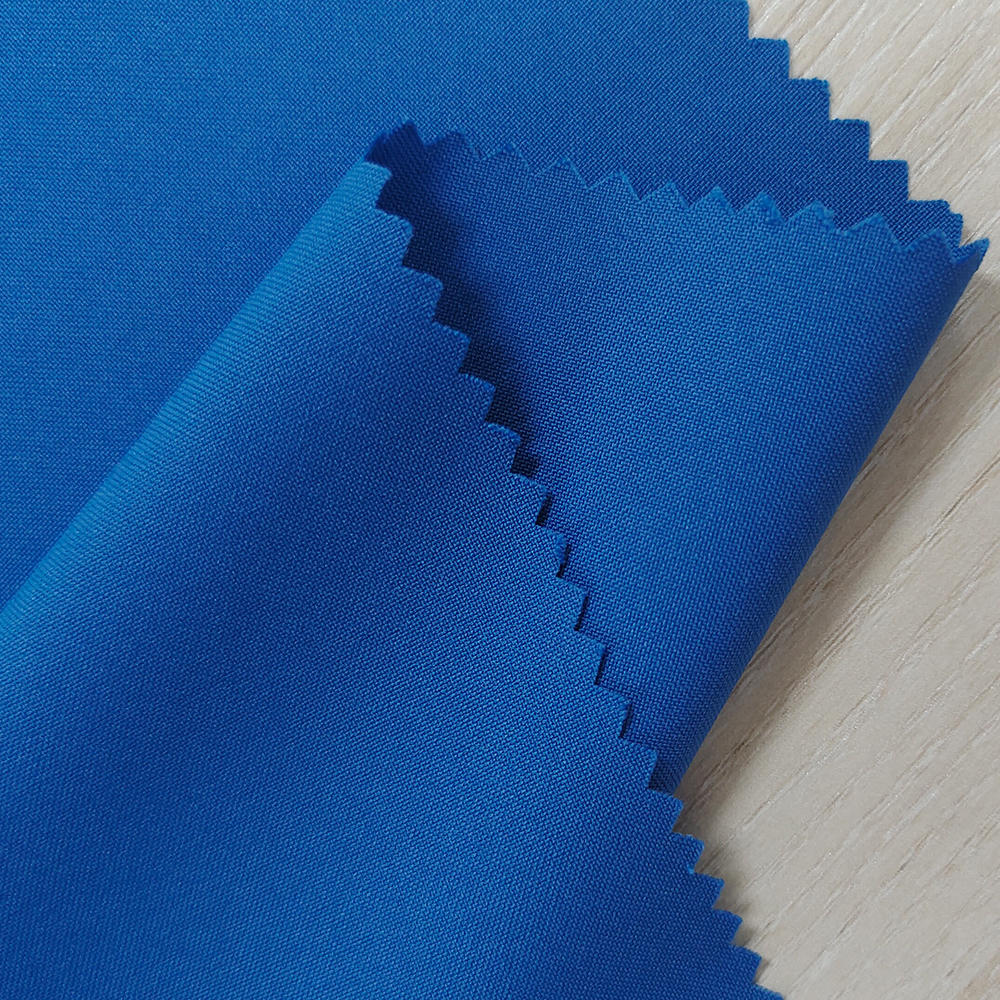

Stretch Direction: Mechanical stretch fabric stretches in two directions, usually horizontally and vertically. This means it expands and contracts along both the warp and weft directions of the fabric.

Construction:

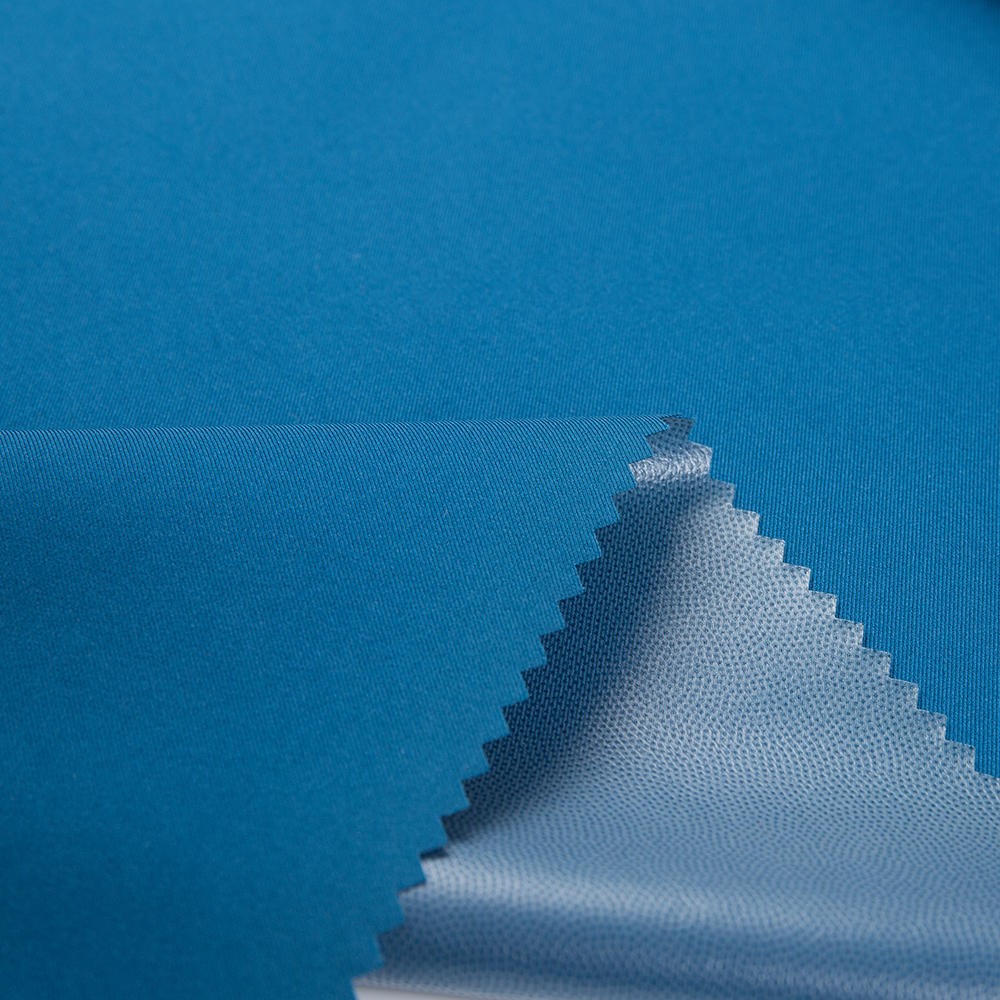

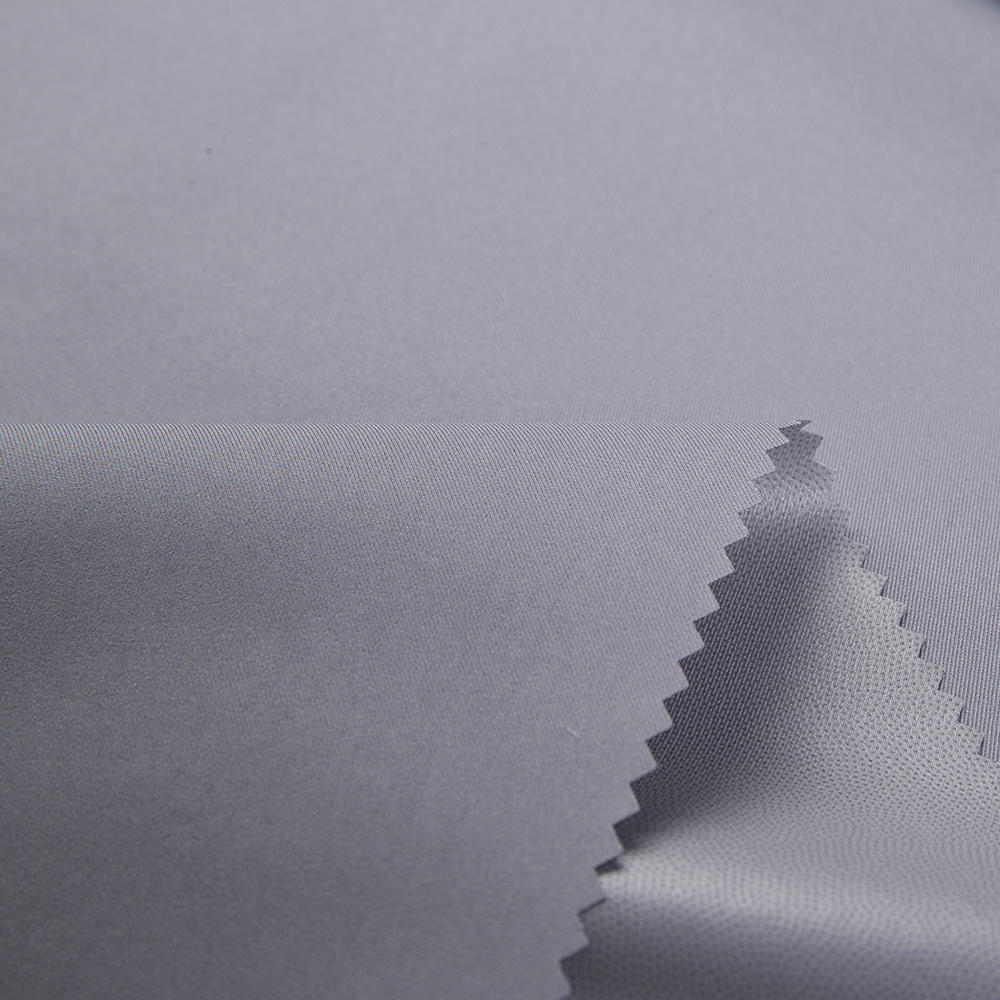

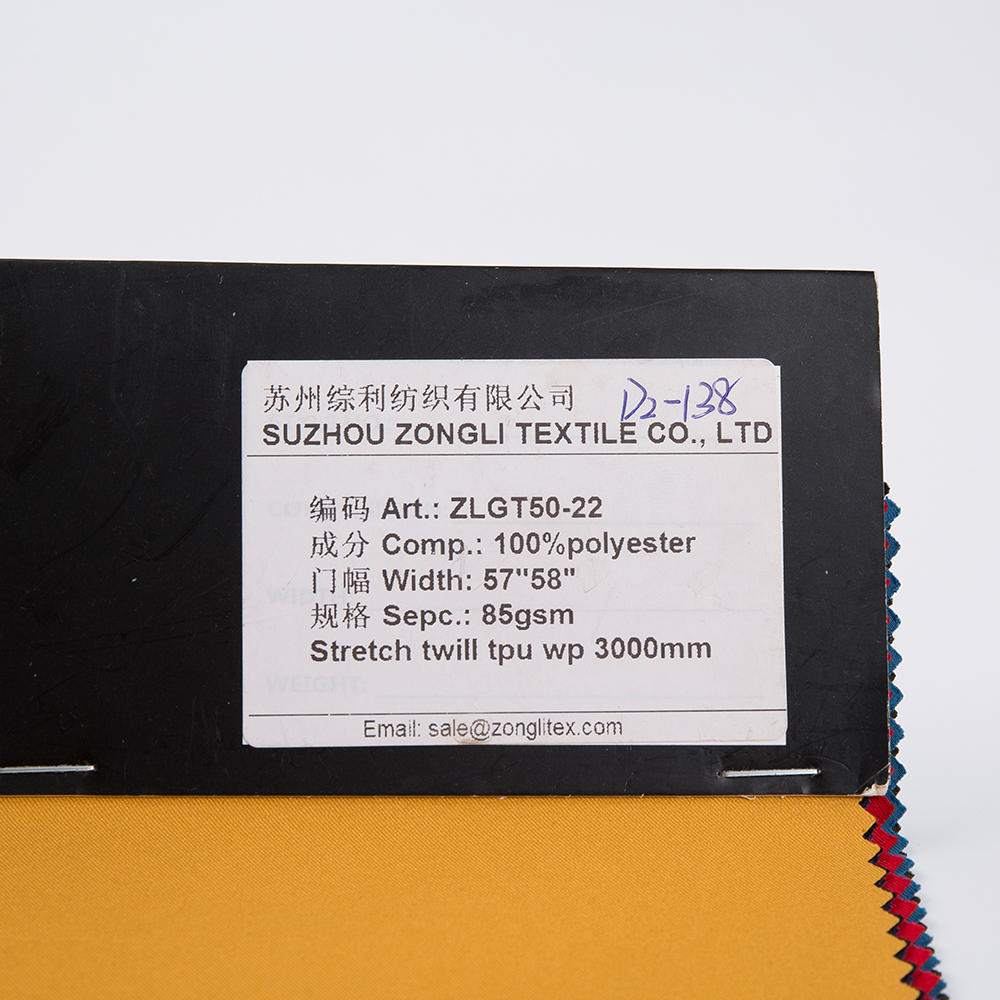

Outdoor Jackets Mechanical stretch fabric is constructed using a special weaving technique that incorporates spandex or elastane fibers into the fabric's structure. These elastic fibers allow the fabric to stretch and then return to its original shape.

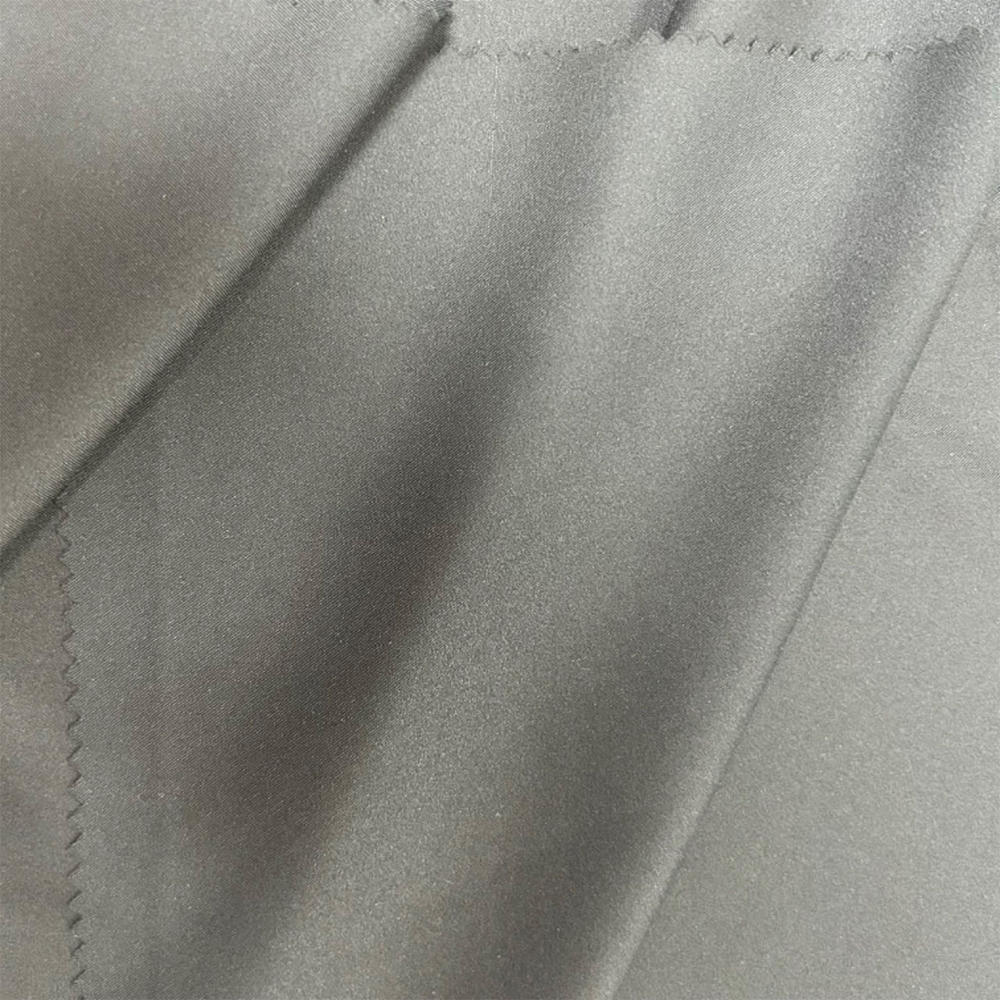

Recovery: One of the main characteristics of mechanical stretch fabric is its ability to recover its original shape after being stretched. It has a high elastic recovery rate, ensuring that the fabric retains its shape and fit even after prolonged use.

Comfort: Mechanical stretch fabric offers a good balance between elasticity and comfort. It provides freedom of movement without feeling restrictive, making it suitable for active wear and garments that require flexibility.

Tailoring: Mechanical stretch fabric is often favored in garment construction as it allows for ease in tailoring. The fabric's stretch properties make it easier to achieve a better fit, minimizing the need for excessive darts or seams.

In contrast to other stretch fabrics, such as four-way stretch fabric or knit fabrics, mechanical stretch fabric has a more limited stretch direction. Four-way stretch fabric, for example, stretches in both horizontal and vertical directions as well as diagonally. Knit fabrics often have a greater degree of stretch in all directions due to their interconnected looped structure.

Additionally, while mechanical stretch fabric offers good stretch and recovery, it may not have the same level of elasticity as other stretch fabrics. Fabrics like Lycra or spandex-blended fabrics can provide higher levels of stretch, compression, and flexibility.

It is important to note that the choice of stretch fabric depends on the specific requirements of the intended purpose or application. Mechanical stretch fabric, with its two-way stretch and balance of comfort and tailoring ease, is often preferred in various clothing items, including pants, skirts, shirts, and jackets.

Why does the stretching direction of Mechanical stretch fabric differ from other elastic fabrics? What determines this?

The stretching course of mechanical stretch fabric differs from other elastic fabric due to the manner it's far manufactured and the materials used.

Mechanical stretch cloth is created with the aid of making use of a mechanical pressure at some stage in the weaving or knitting manner. This pressure causes the

Outdoor Jackets Mechanical stretch fabric to elongate and create a stretch effect. The stretching route of mechanical stretch material is decided via the orientation and association of the fibers or yarns during this system. The fibers or yarns are typically organized in a parallel or diagonal manner, which allows for stretch most effective in particular directions.

On the alternative hand, elastic fabrics are made with the inclusion of elastic fibers together with spandex or elastane. These fibers possess herbal elasticity, which provides the cloth with stretch in more than one directions. The elastic fibers may be knitted, woven, or combined with other fibers to create a cloth that stretches lightly in all guidelines.

Therefore, the distinction in stretching course between mechanical stretch material and different elastic fabric is frequently because of the producing strategies and the presence of elastic fibers. Mechanical stretch fabric stretches predominantly inside the predetermined directions determined during the weaving or knitting technique, at the same time as elastic fabrics stretch uniformly in all directions because of the inherent homes of the elastic fibers used.