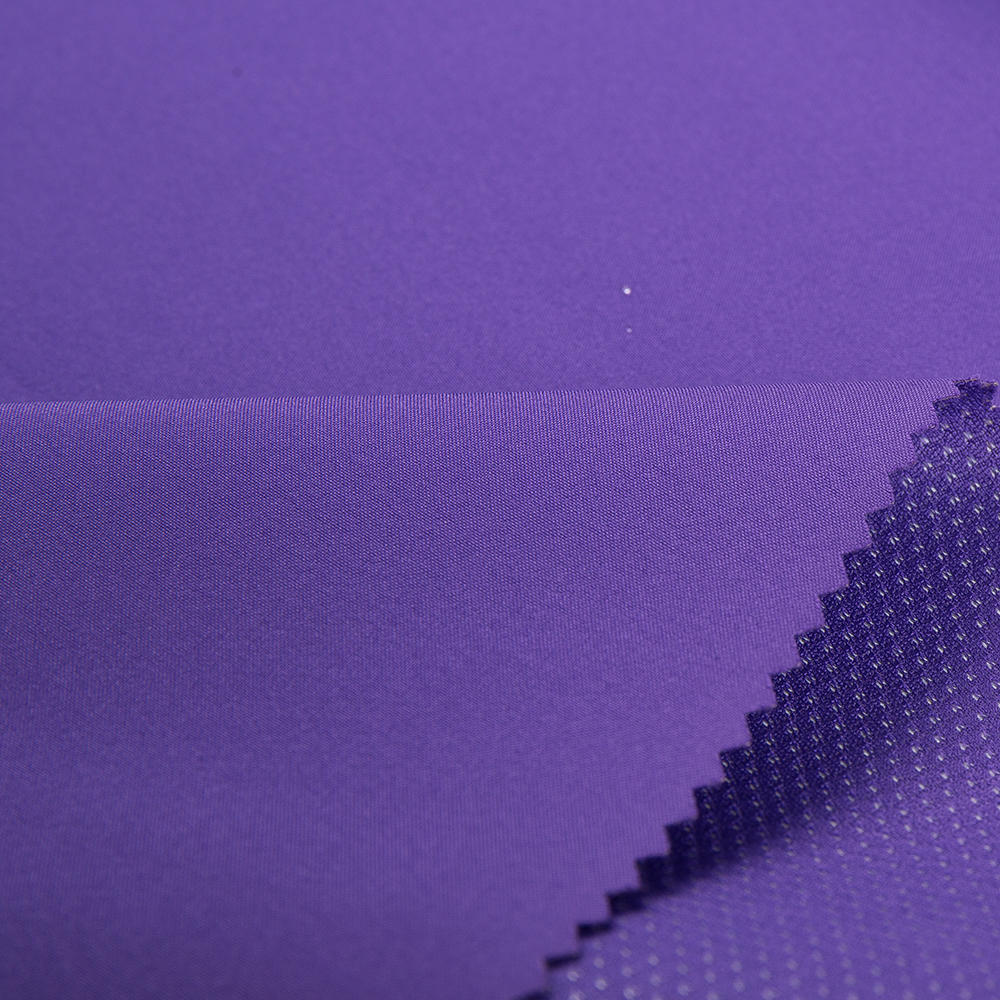

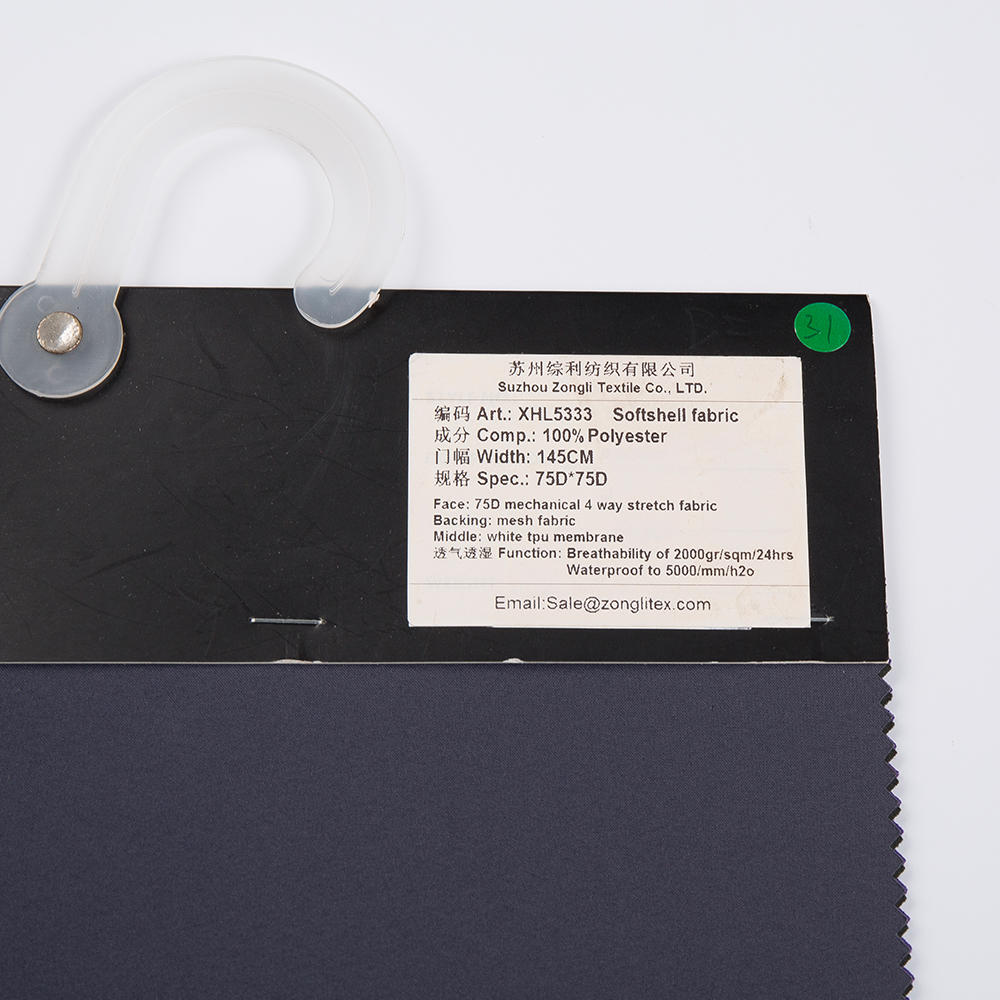

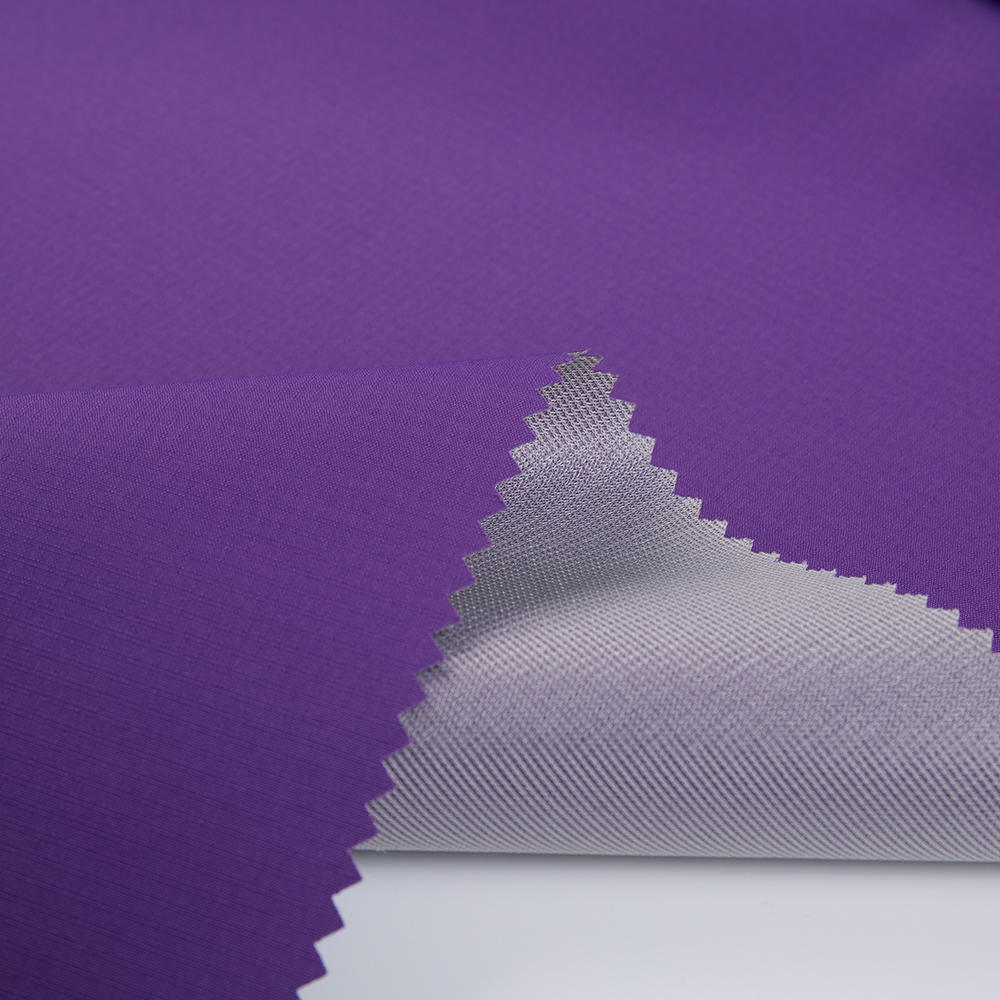

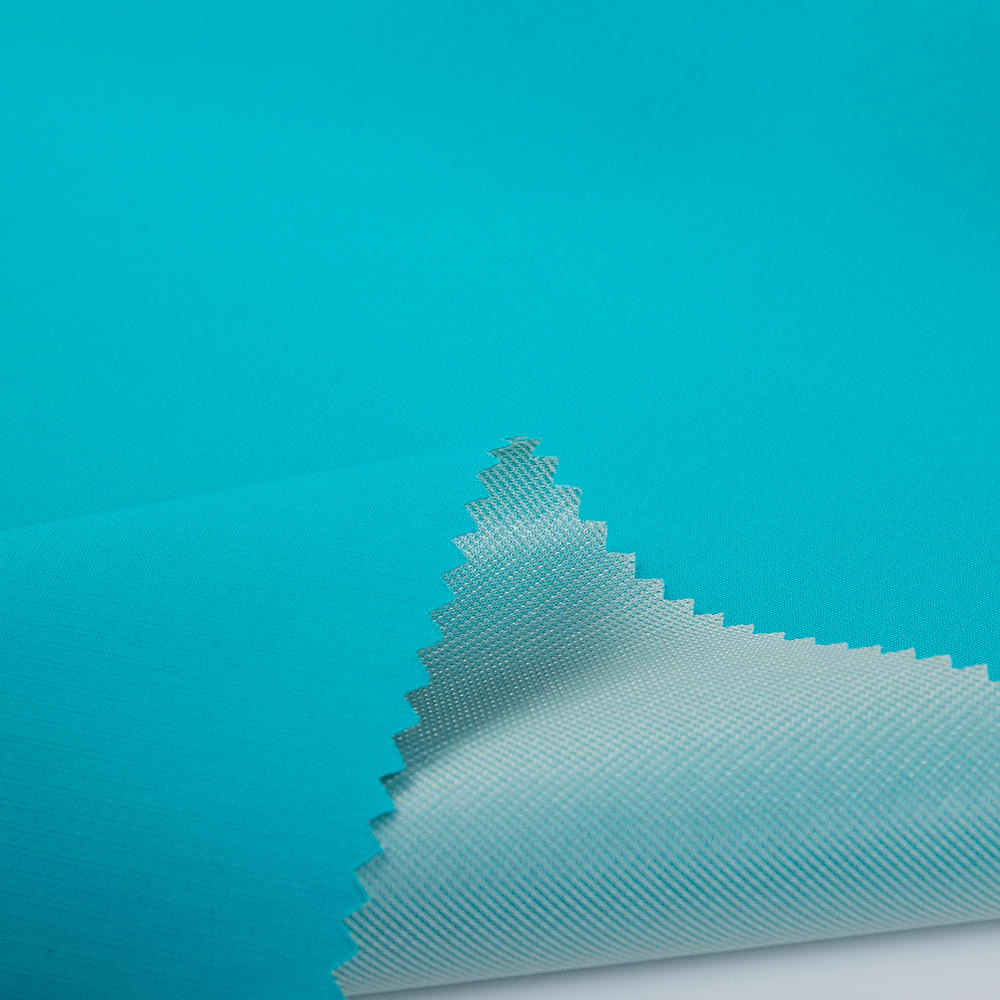

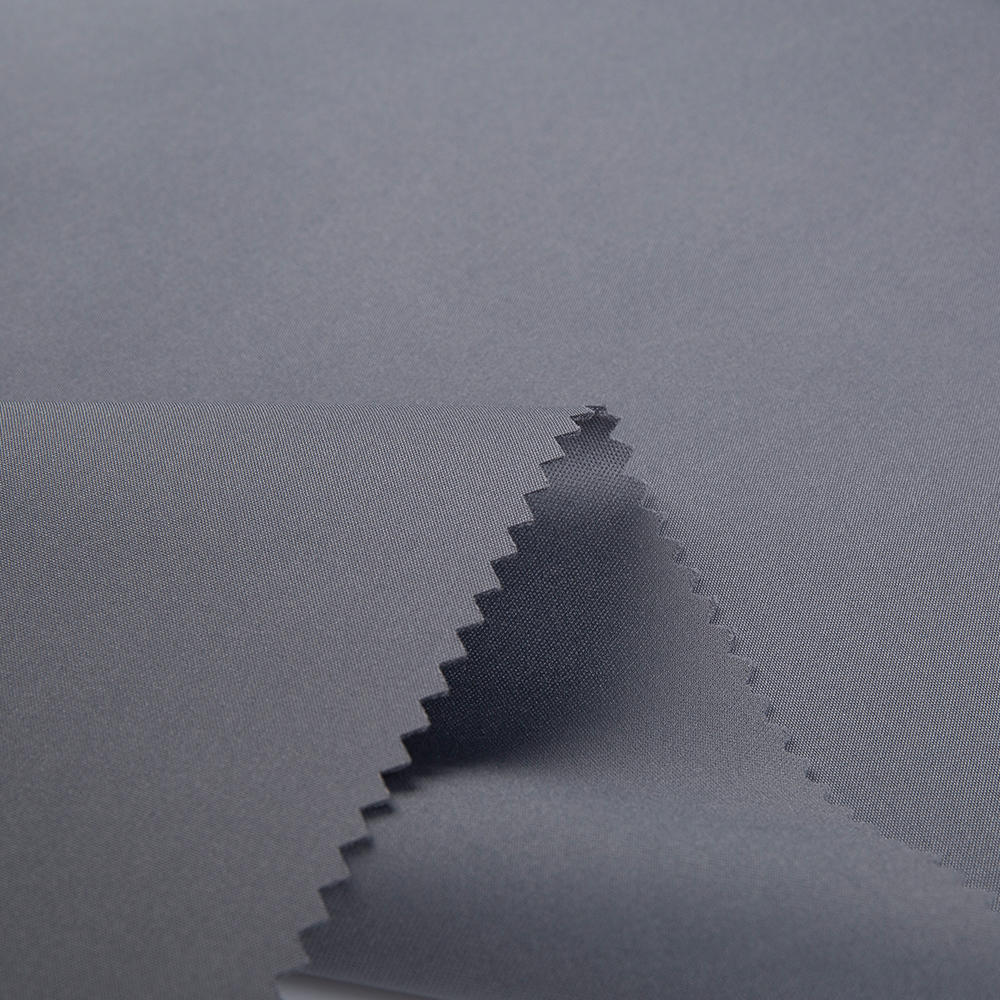

The development of new coating and membrane technologies in hardshell fabrics is leading a revolution that aims to balance water resistance with lightweight. One common approach among these innovative technologies is the use of nanocoatings or films. These nanomaterials stand out for their tiny particle size and outstanding properties. They form a tiny protective layer on the surface of the fabric, providing reliable waterproofing while adding virtually no weight. This technology allows hard-shell garments to be lighter and more comfortable for wearers during outdoor activities.

In addition, multi-layer coatings or film structures are also widely used to improve the performance of hard-shell fabrics. By stacking multiple membrane layers on top of each other, higher water resistance can be achieved, while each membrane layer can be designed to be very thin, thus reducing overall weight. This multi-layer construction provides excellent protection, allowing hard shell garments to withstand harsh weather conditions.Use this fabric to make

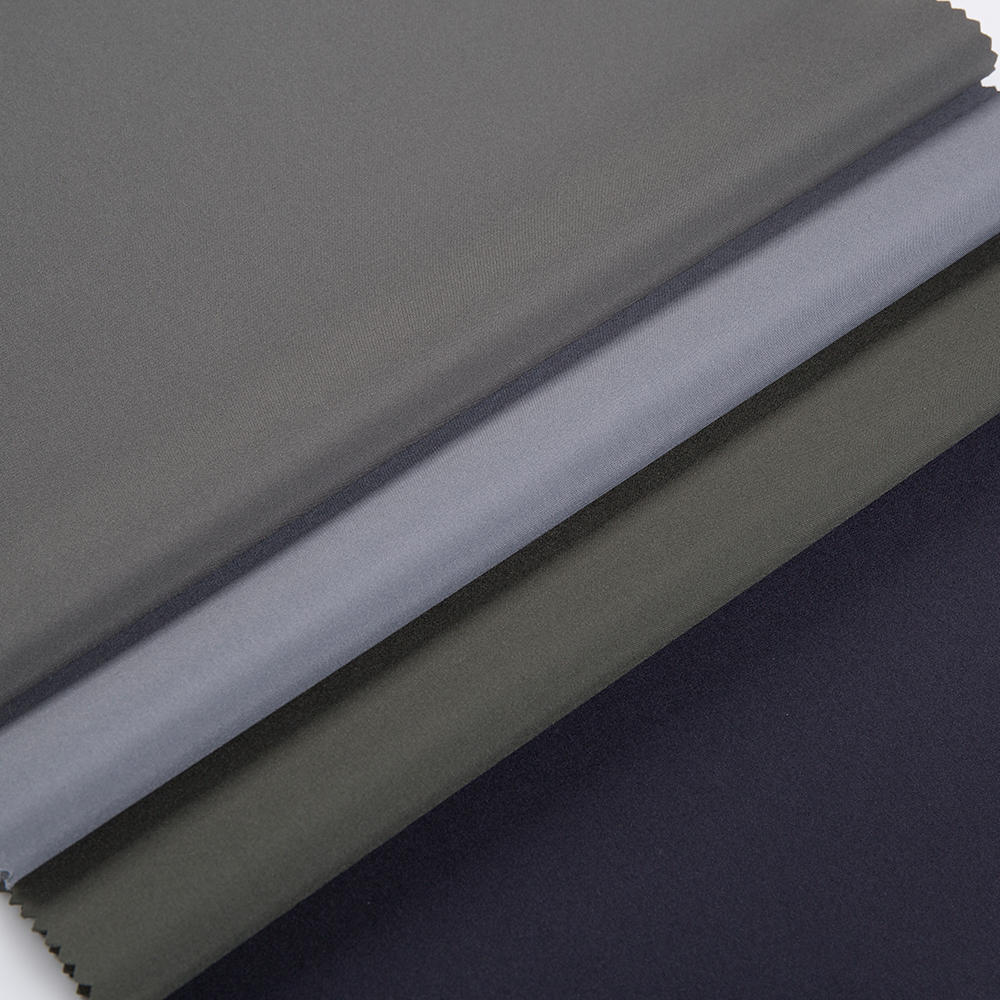

Outdoor Sportswear Hardshell fabric so you don't have to worry about the effects of bad weather.

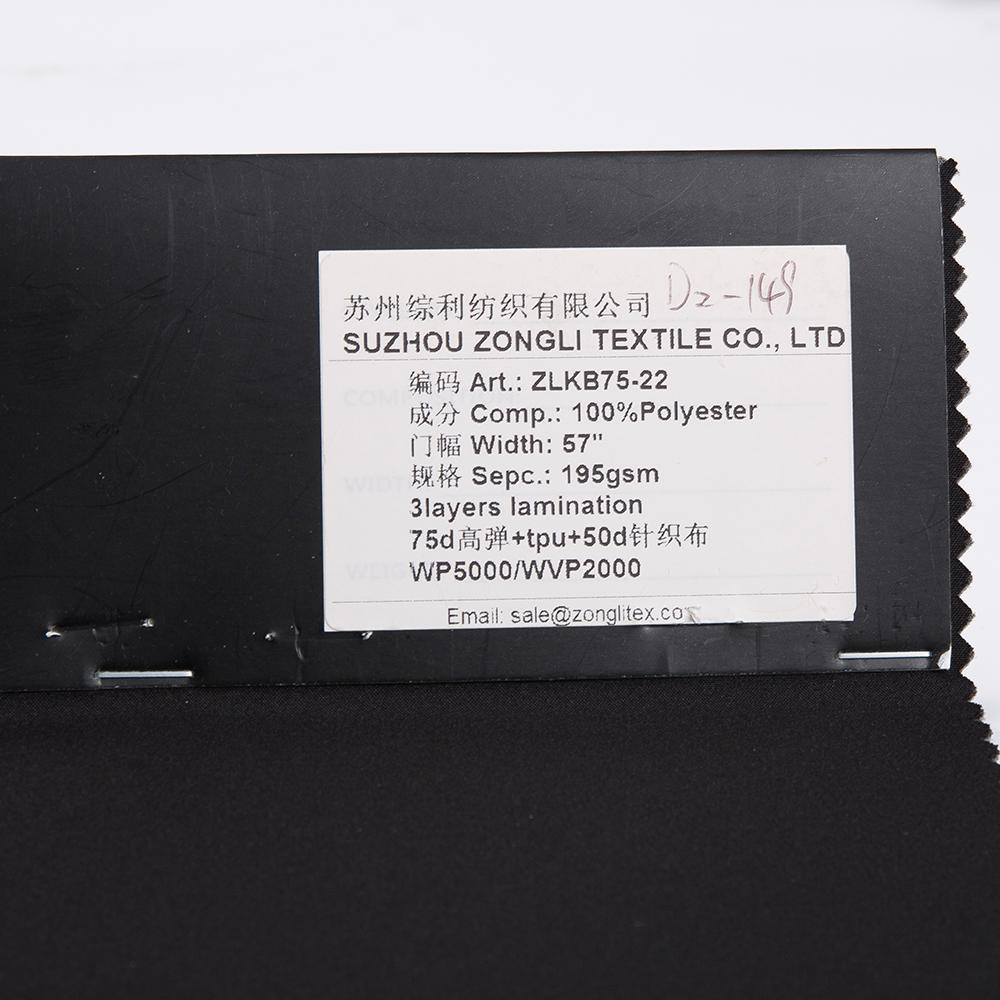

At the forefront of coating and film technology, the use of new materials is also becoming increasingly common. For example, some polymers or polyester-based materials have been used in coatings or films for hard-shell fabrics. The lighter density of these materials allows for lightweight designs while maintaining excellent waterproofing properties.

In summary, innovative coating and membrane technologies in the hardshell space are centering around lightweighting and are designed to provide reliable waterproof performance while ensuring optimal comfort for the wearer during a variety of outdoor activities. Continued advancements in these technologies will continue to drive the development of hardshell apparel to meet the needs of different activities and climate conditions.

What special stitching and seaming techniques are used in hardshell fabric garments in curved areas to ensure these areas are waterproof?

Waterproof garments often have special stitching and seaming techniques in curved areas to ensure that these areas remain waterproof. Here are some common techniques used:

Some high-quality

Outdoor Sportswear Hardshell fabric are designed without any stitching in curved areas. This seamless design eliminates potential points of water penetration caused by stitching, making sure the garment remains completely waterproof.

Elastic sutures are commonly used in curved areas to ensure flexibility and reduce the risk of water leakage. These sutures stretch and move with the body, relieving tension in these areas and minimizing the chance of water seeping through.

Hot melt seaming technology is another method used for curved areas. It involves bonding two fabric pieces together with hot melt glue, creating a durable and seamless connection that ensures reliable waterproofing.

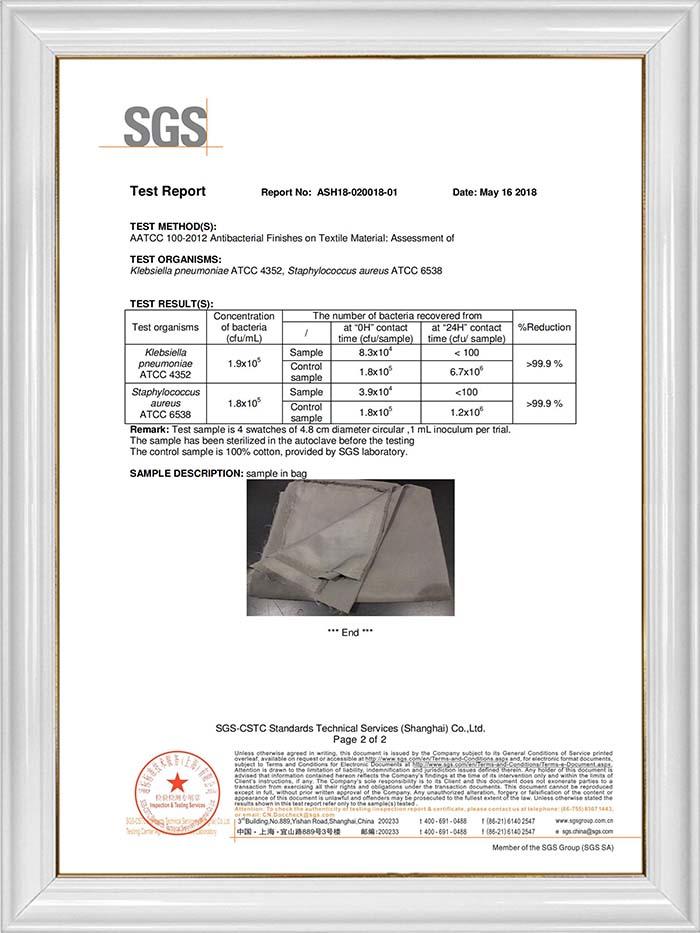

In some hard-shell fabrics, special coating or film technology is applied to the curved area to enhance water resistance. These areas undergo additional treatment to improve their ability to resist moisture penetration.

To ensure the waterproof performance in curved areas, multiple durability tests are conducted. These tests simulate various conditions experienced during outdoor activities, such as bending, stretching, and twisting. By evaluating the garment's performance under these conditions, its waterproofing properties can be assessed and improved if necessary.

In conclusion, waterproofing in curved areas requires a combination of techniques and methods to ensure the garment remains dry and comfortable during outdoor activities. These methods aim to minimize the risk of water penetration and enhance the performance of the garment in these areas.