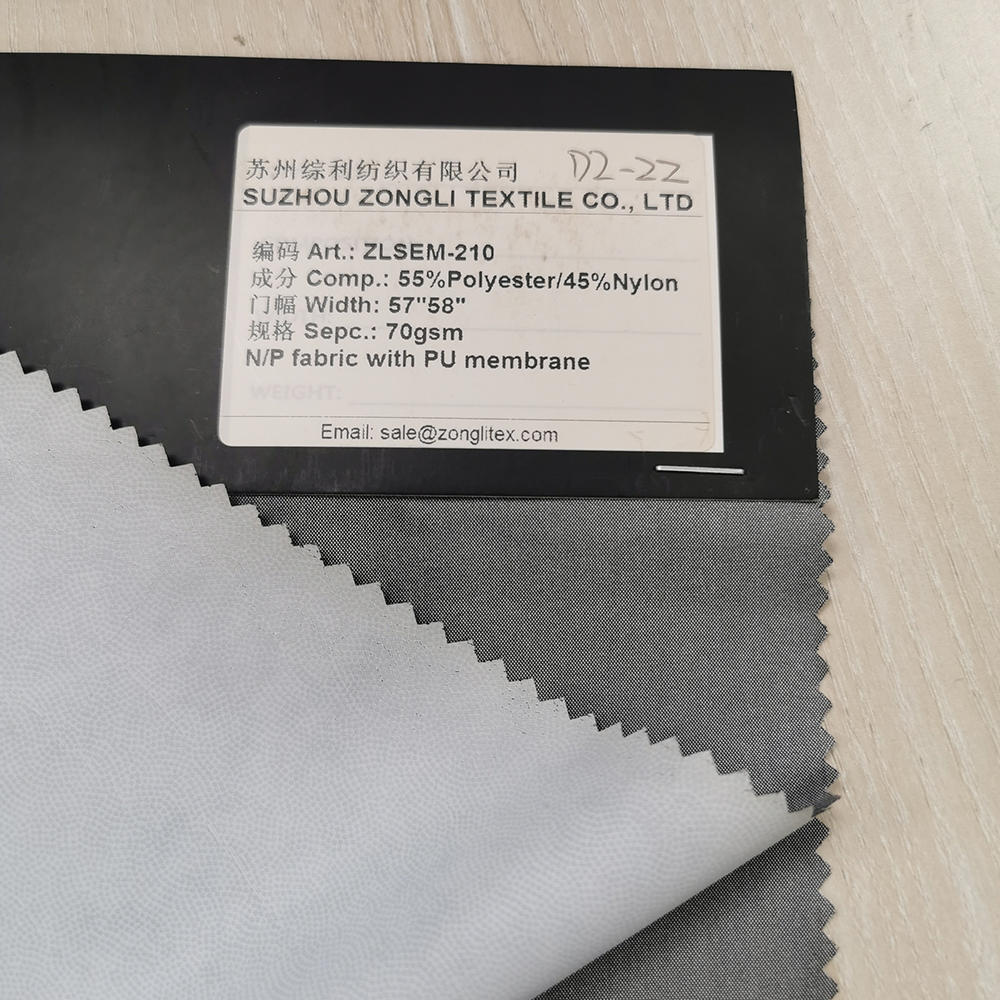

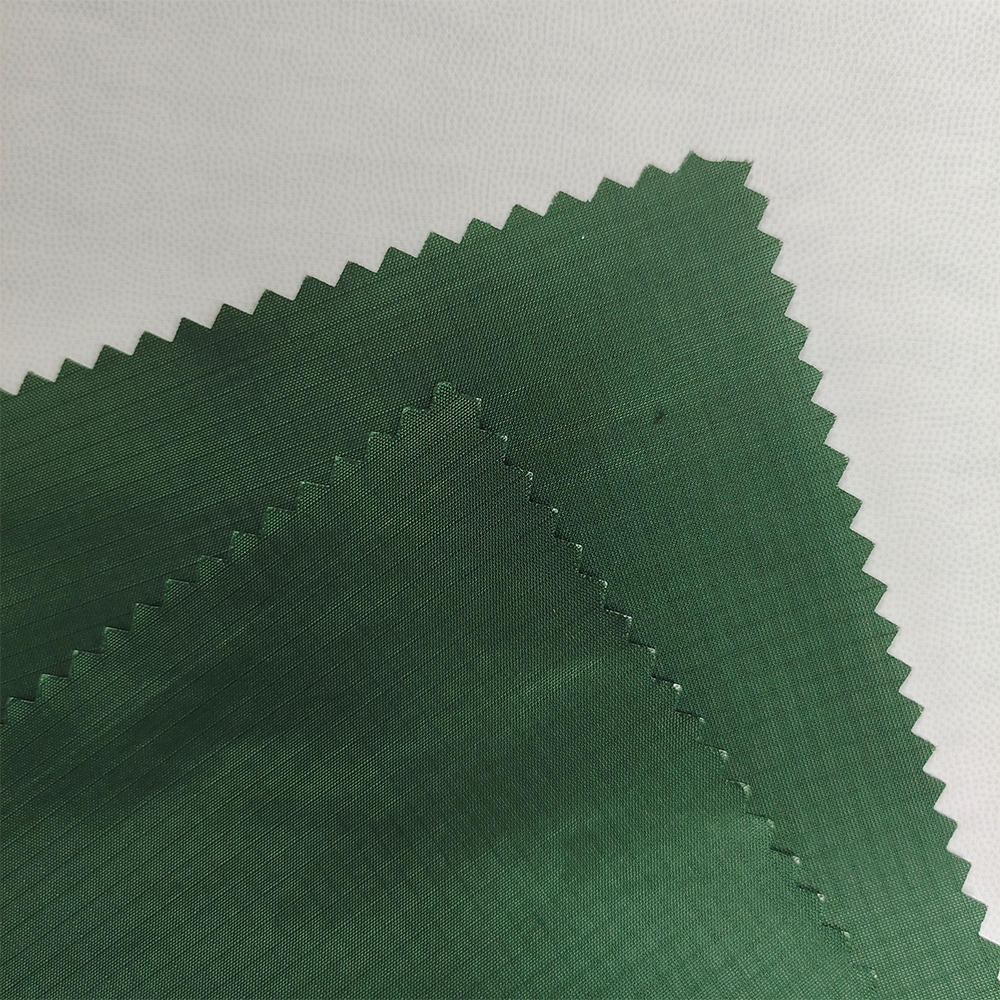

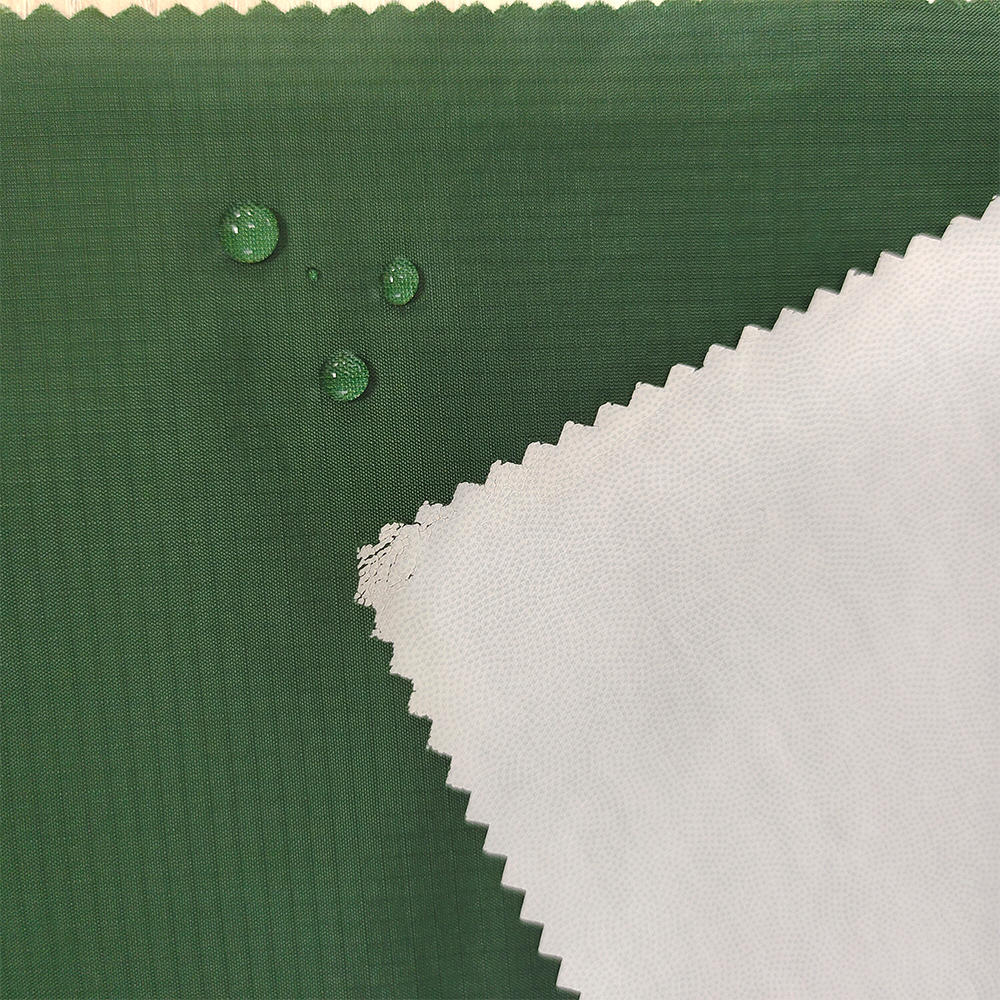

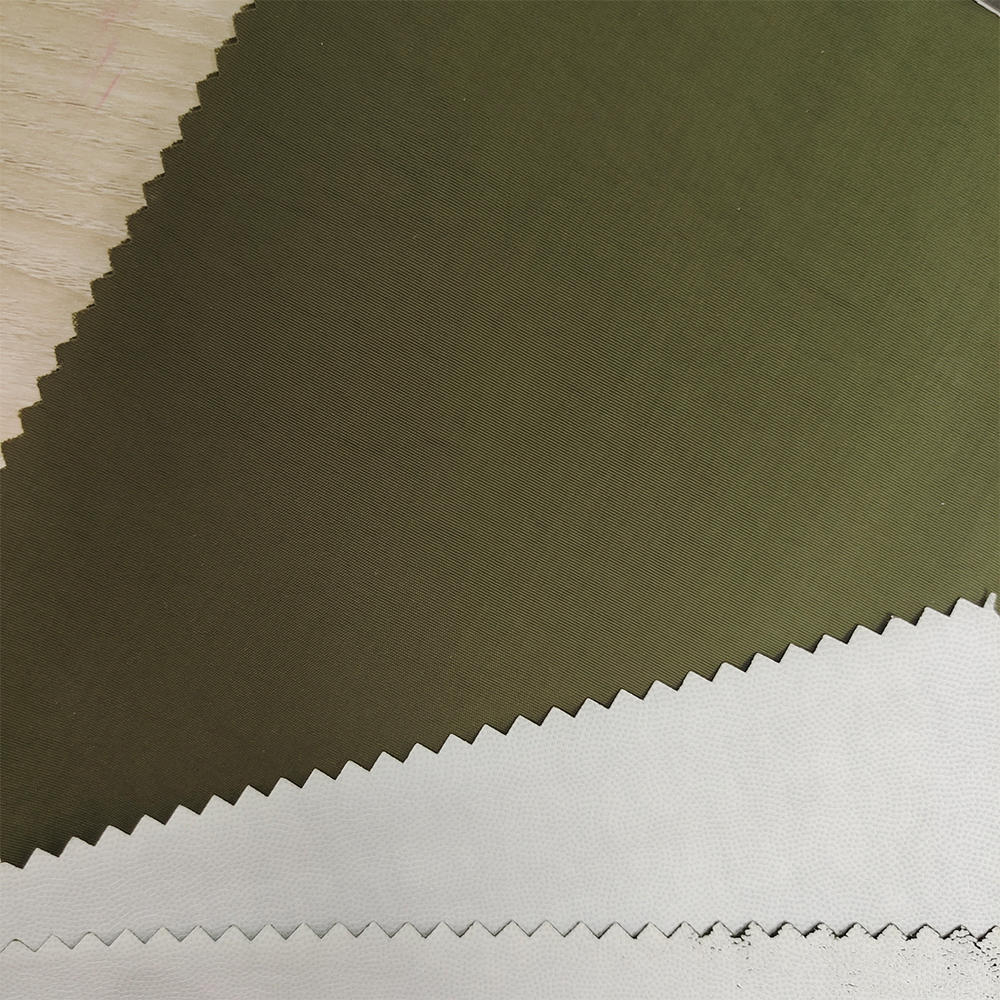

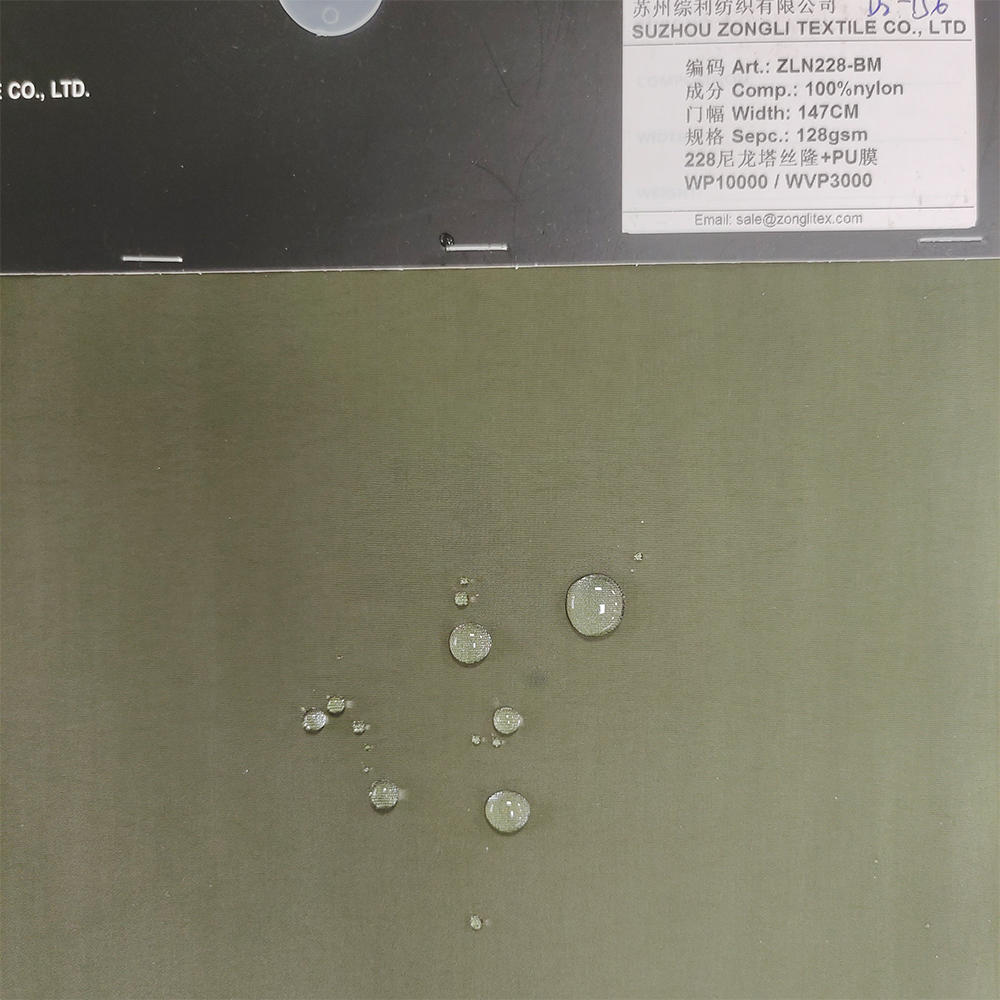

PU (Polyurethane) laminated cloth is a quite powerful desire for applications requiring resistance to corrosion and safety in opposition to diverse environmental elements. The fabrication manner includes making use of a layer of polyurethane coating onto the fabric, and this coating is instrumental in forming a protecting barrier that shields the cloth from corrosive retailers, which include water, moisture, or chemical compounds.

The shape of the PU coating is necessary to its resistance against corrosion. PU coatings are composed of a polymeric cloth that boasts amazing resistance residences. The dense and impermeable structure of the polyurethane coating acts as a sturdy guard, preventing corrosive substances from getting into direct touch with the cloth. This impermeability is specially valuable in safeguarding the material from the damaging outcomes of water, moisture, and chemical compounds, which could otherwise cause corrosion and degradation.

In addition to its impermeable nature, PU coatings provide noteworthy resistance against UV radiation. Exposure to UV radiation may be a huge element within the deterioration and corrosion of substances through the years. PU-coated fabrics, with their inherent UV resistance, are better equipped to face up to the harmful consequences of prolonged solar exposure, making sure lengthy-lasting overall performance and durability.

PU laminated material is predicated at the structure and technique of the PU coating to offer a strong defense against corrosion. The impermeable and UV-resistant nature of the PU coating, along side the meticulous utility process that guarantees a uniform and non-stop layer, makes PU laminated fabric an ideal preference for a wide range of packages where protection in opposition to corrosion is critical.

What are the primary considerations in selecting PU laminated fabric for medical or healthcare applications, and how does it meet safety and regulatory standards for these industries?

When deciding on

PU laminated fabric for scientific or healthcare applications, several primary considerations want to be taken into account. These considerations include:

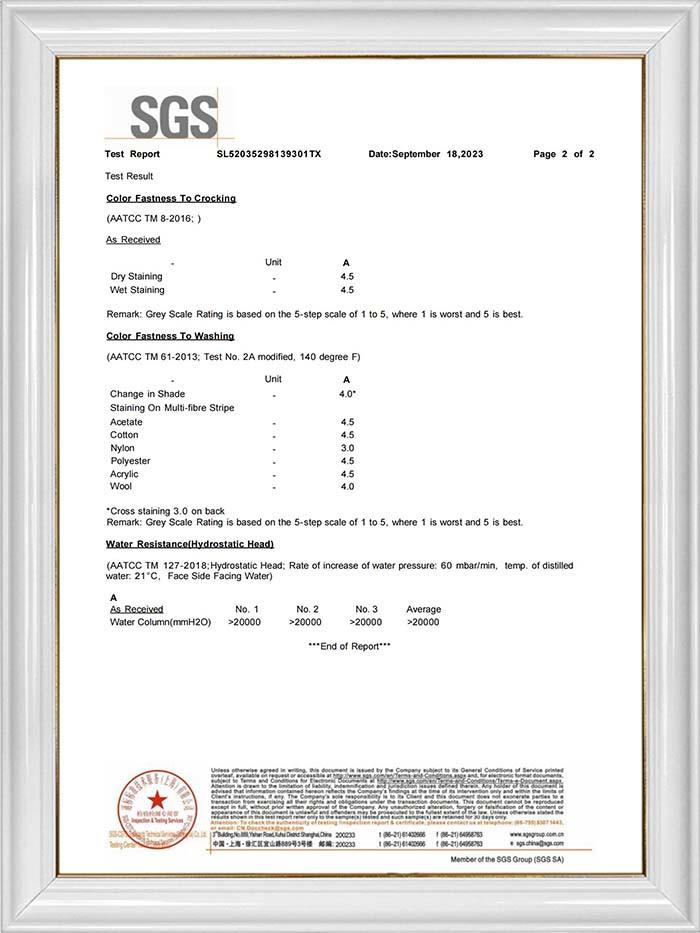

One of the most important factors is the potential of the cloth to provide a barrier towards beverages, microorganisms, and different contaminants. The material have to have a high stage of impermeability to make sure the safety of healthcare specialists and sufferers.

PU laminated cloth should offer breathability and comfort to the wearer, as it's miles regularly utilized in garments, beddings, or other textile merchandise for clinical settings. It should permit air movement to save you immoderate sweating and discomfort for the user.

The cloth have to be robust and tear-proof against face up to the pains of medical or healthcare environments. It should be able to bear common laundering, sterilization, and other cleaning techniques without losing its capability or integrity.

Medical settings often involve publicity to diverse chemical substances, disinfectants, and cleansing retailers. The PU laminated cloth have to be resistant to these chemical substances to make sure its durability and overall performance.

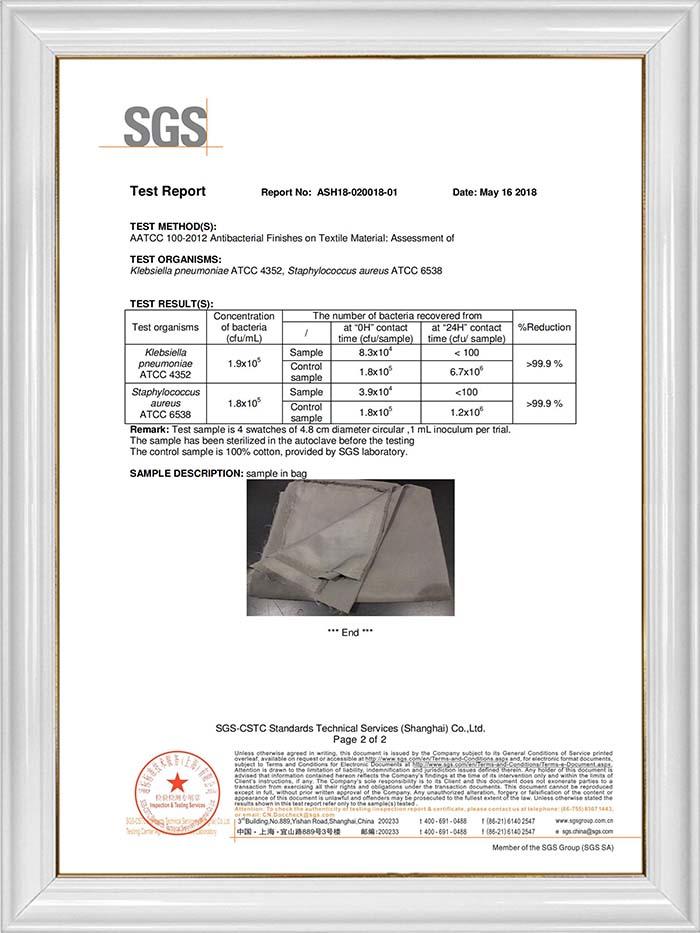

PU laminated cloth used in clinical or healthcare programs need to meet precise safety and regulatory requirements set with the aid of governing our bodies inclusive of the FDA (Food and Drug Administration) or European Medicines Agency. These standards make certain that the fabric is secure to be used in medical settings and does now not pose any damage to sufferers or healthcare specialists.

1. Material selection: They select substances that comply with relevant standards and policies, consisting of being free from dangerous substances or allergens. This can also involve the usage of medical-grade polyurethane (PU) or other licensed materials.

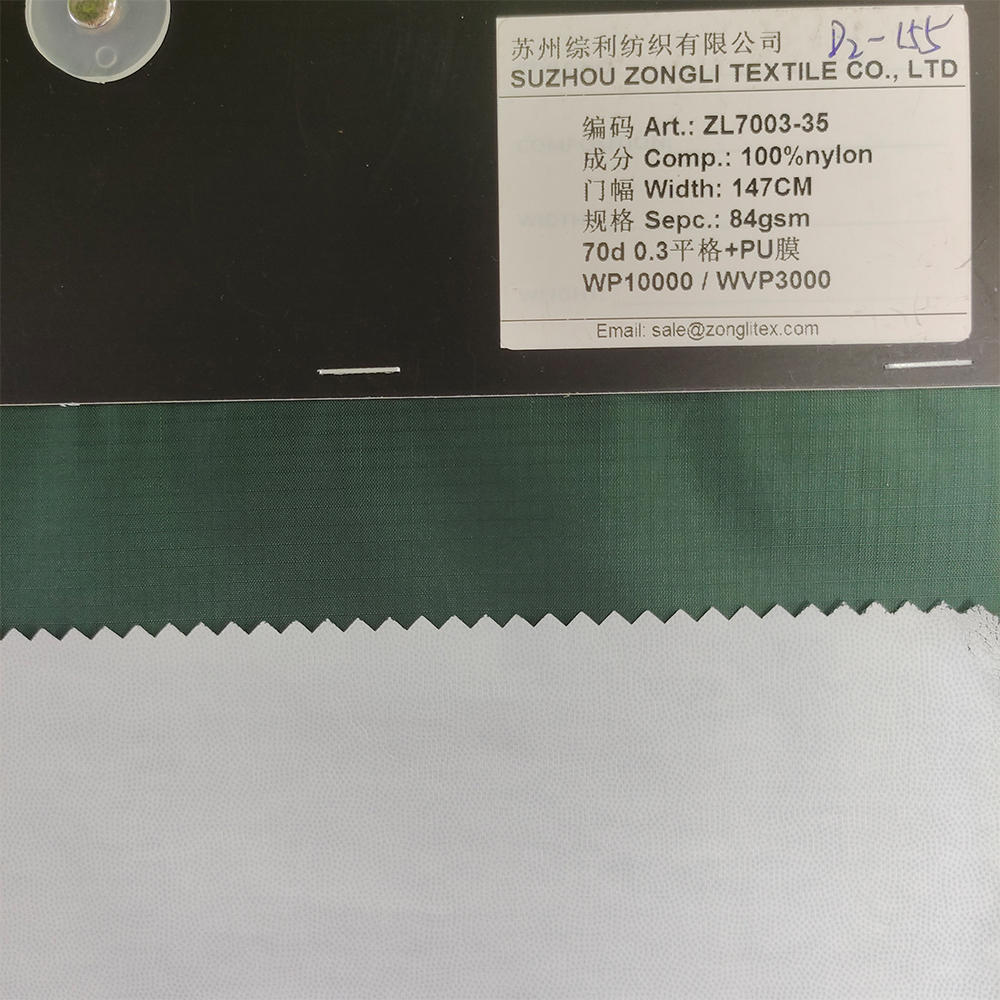

2. Testing and certification: The material undergoes rigorous trying out to decide its compliance with requirements for elements like liquid repellency, microbial penetration resistance, breathability, and durability. Testing can consist of reviews of cloth integrity, liquid barrier performance, and biocompatibility.

3. Quality control and production approaches: Manufacturers enforce strict great manage measures in their production techniques to ensure the consistency and reliability of the cloth. This includes monitoring adherence to safety policies for the duration of manufacturing, which include keeping a clean and sterile surroundings.

4. Documentation and labeling: Manufacturers provide documentation and labeling that absolutely state the compliance of their PU laminated fabric with applicable protection and regulatory requirements. This records permits healthcare specialists and clients to verify the material's suitability for clinical programs.

Meeting protection and regulatory requirements is crucial in the scientific and healthcare industries to protect patients, healthcare specialists, and hold the overall integrity of merchandise used in these settings.