How versatile is Waterproof Breathable Fabric for Coats and Jackets in adapting to different clothing styles and designs?

Waterproof breathable fabrics (WBF) for coats and jackets are relatively flexible and versatile in adapting to different garment patterns and designs. Here are some reasons:

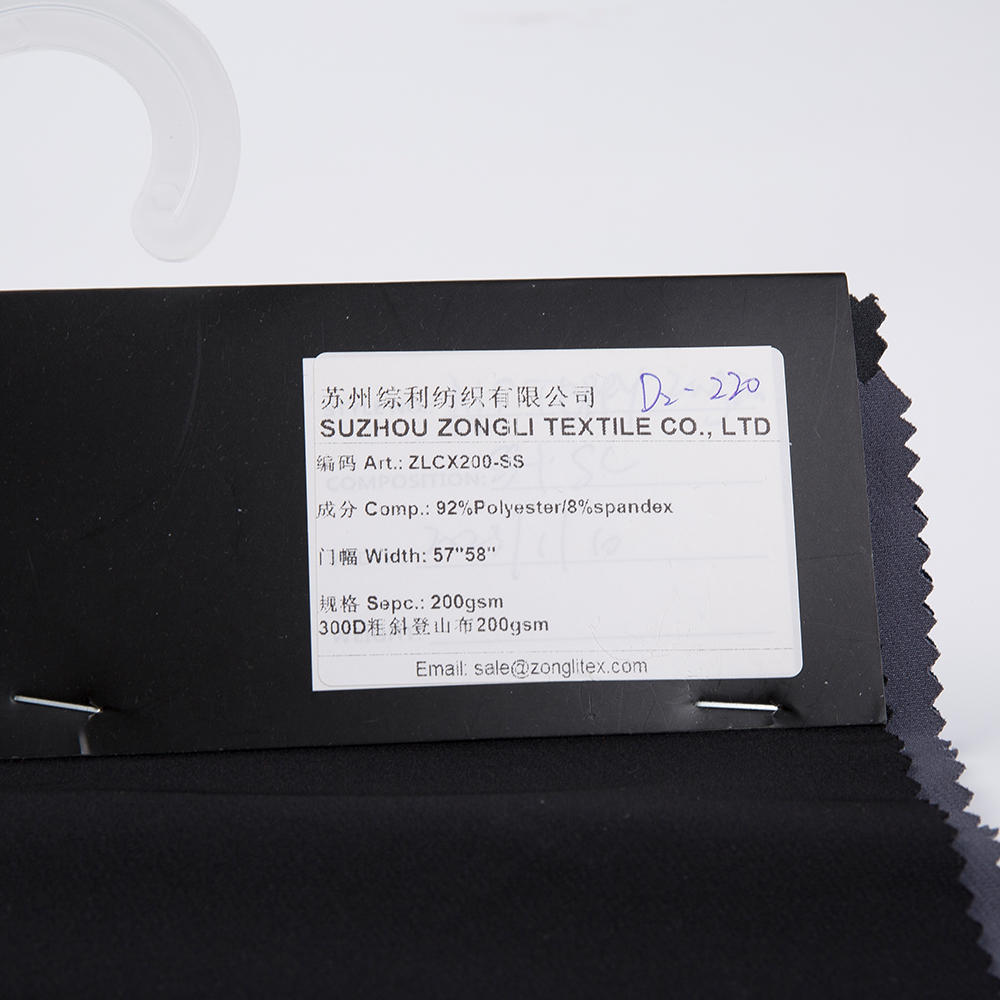

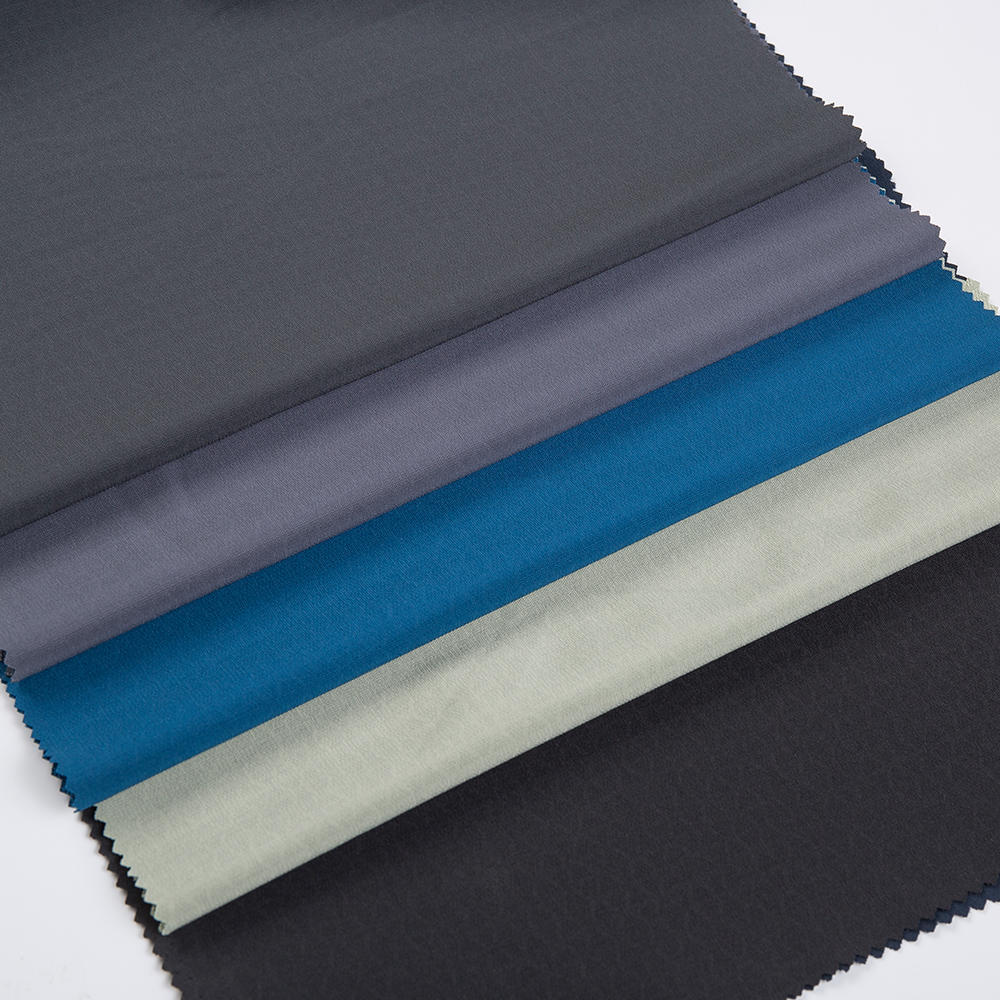

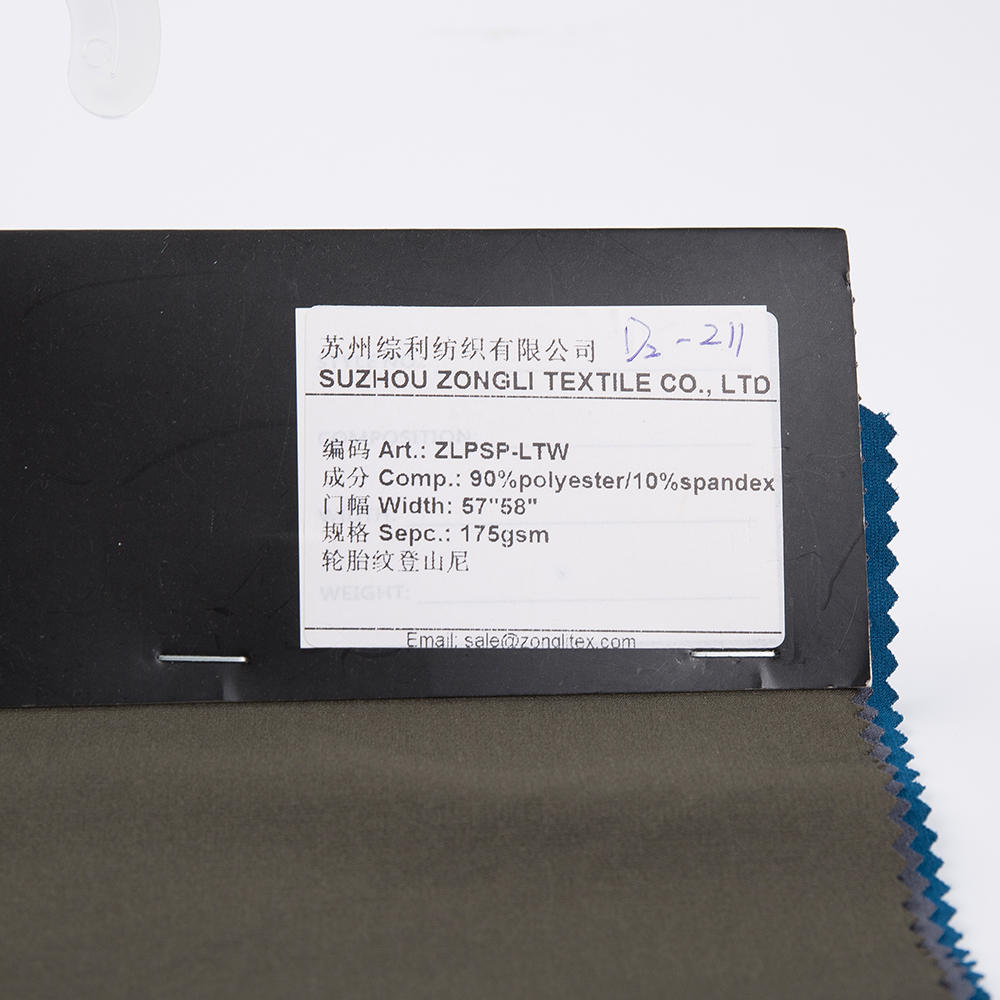

Available in Different Thicknesses and Weights: WBF is available in different thicknesses and weights, making it usable in every type of jacket or coat. For example, heavier winter outdoor jackets, lightweight and foldable raincoats, etc.

Compatible with a variety of clothing constructions: WBF can be used in special clothing constructions, including soft shell jackets, hard shell jackets, down jackets, windbreakers, and more. It can be incorporated into a variety of styles, from sporty outdoor gear to urban style.

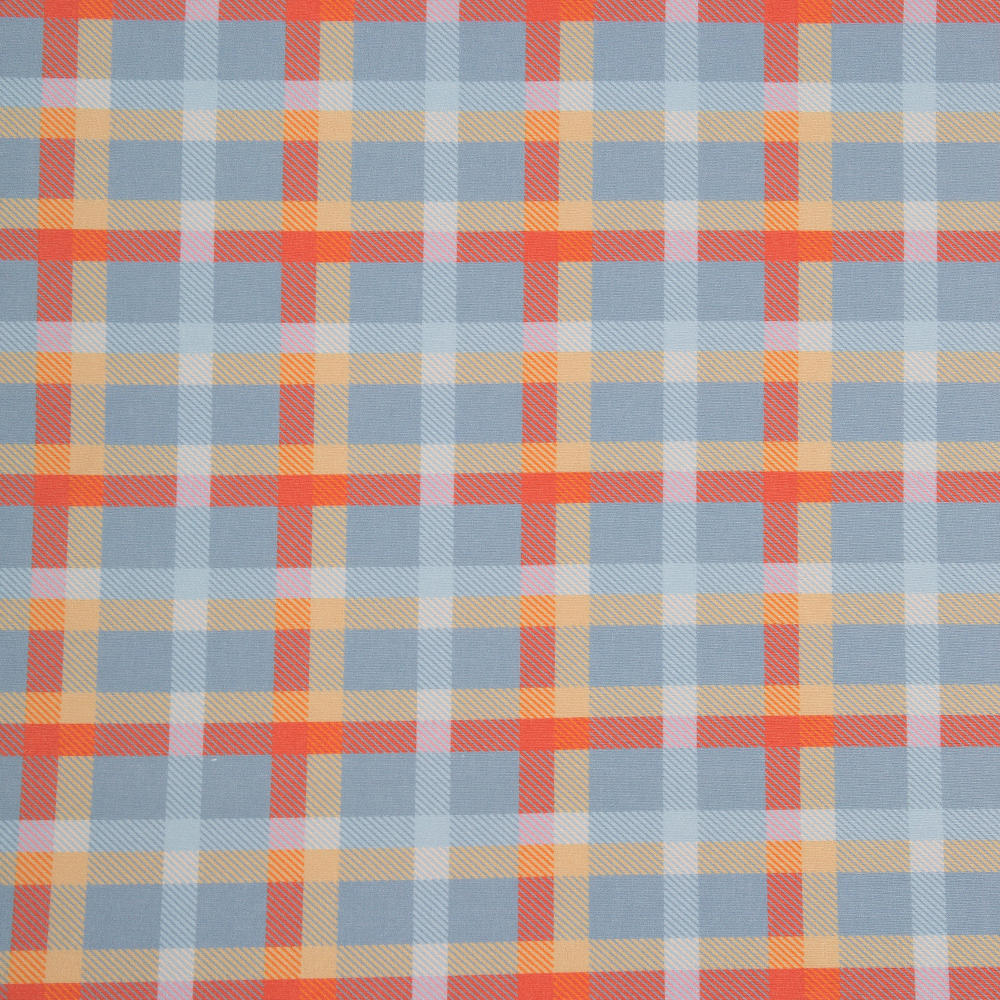

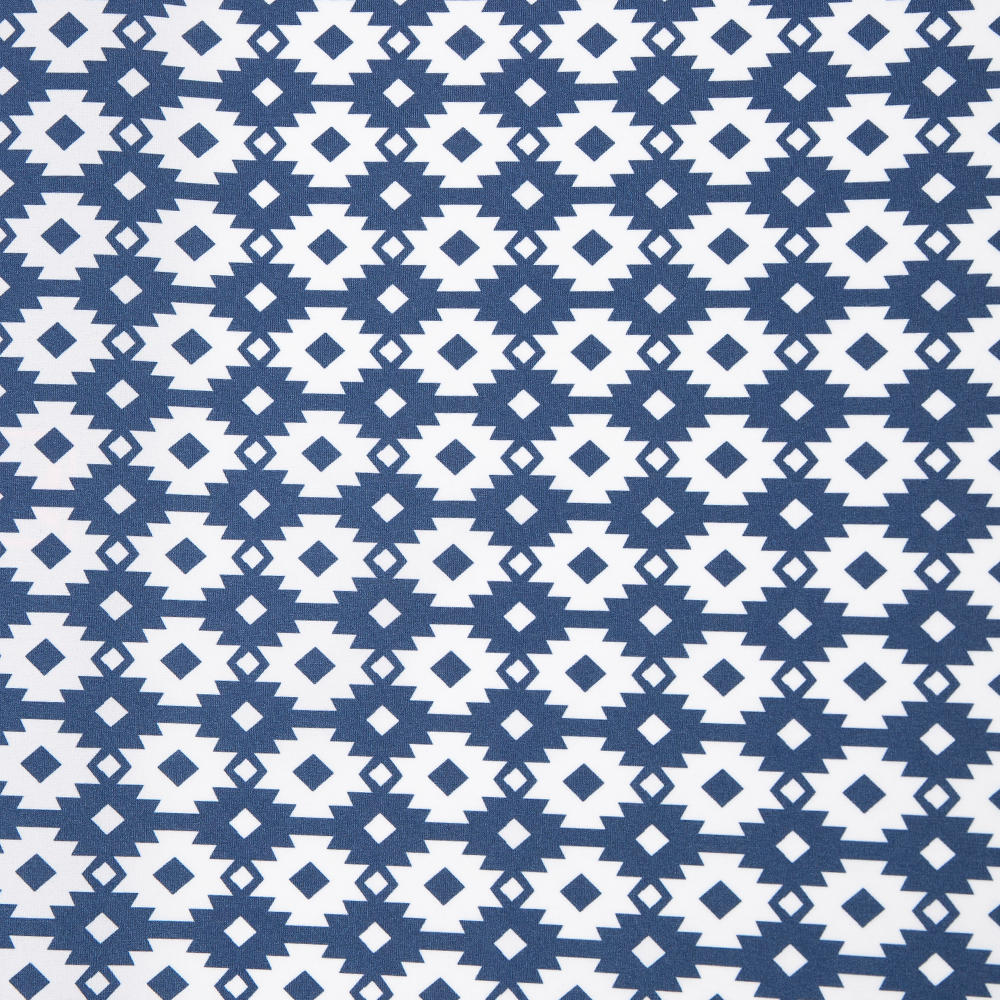

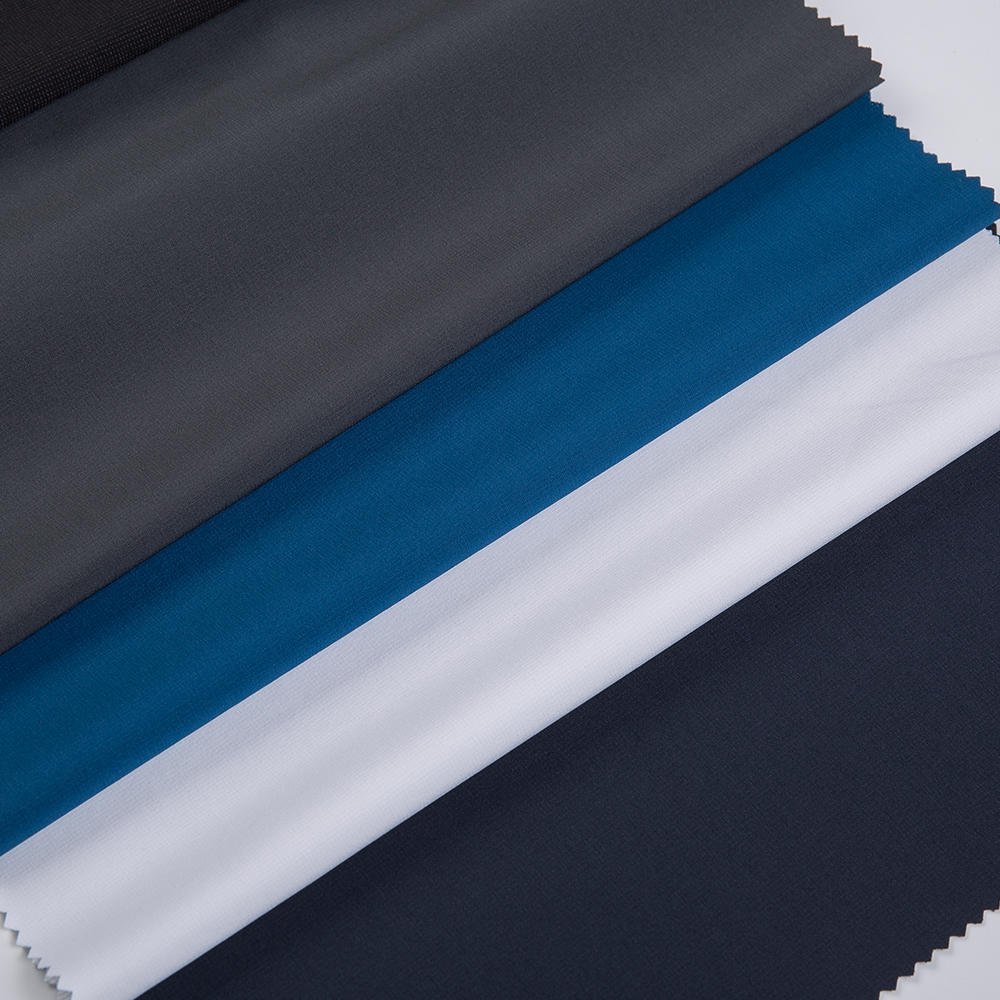

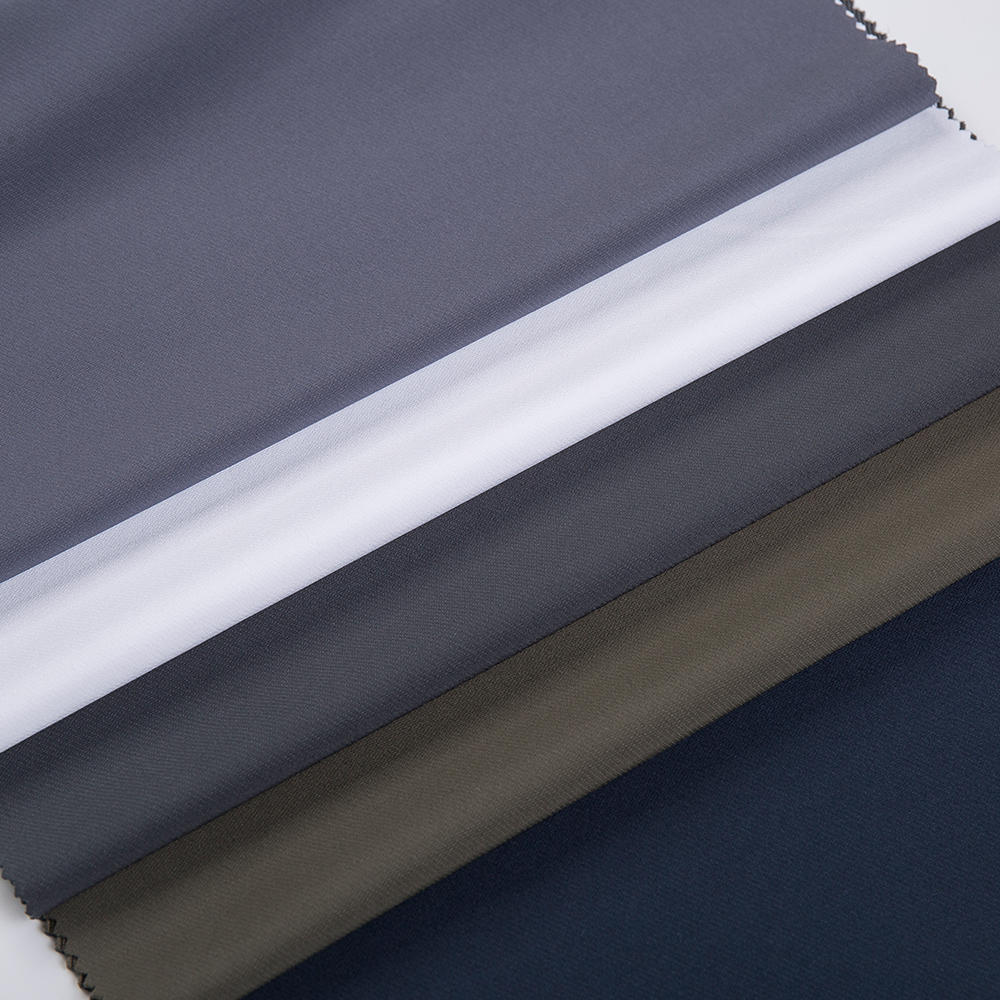

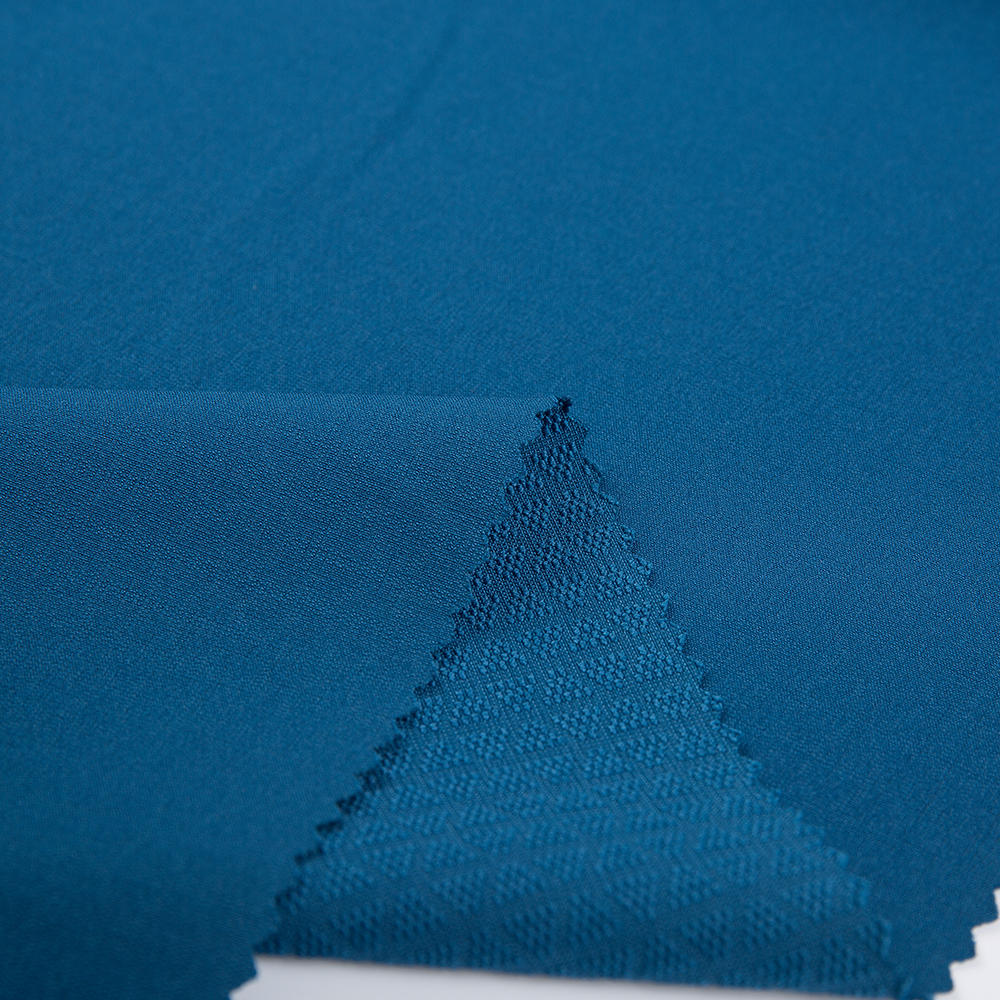

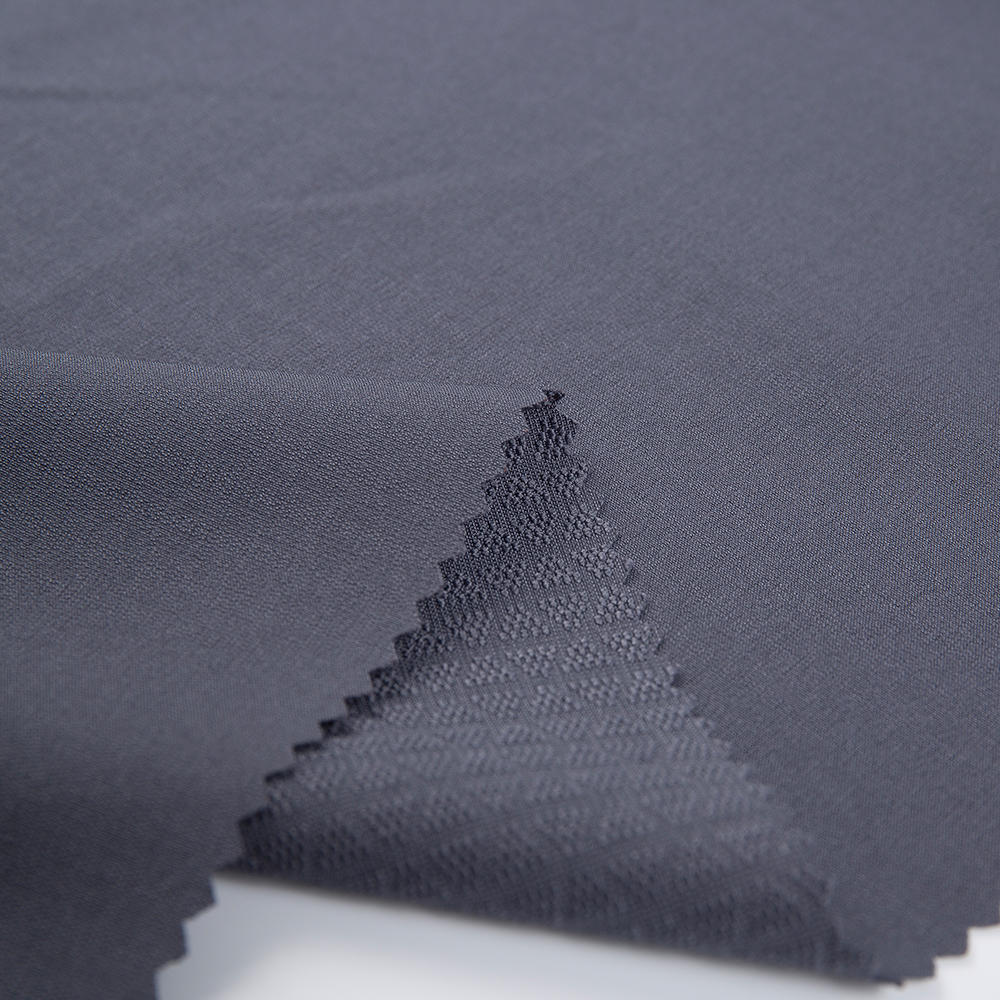

Dyeing and Printing Options: WBF can be dyed or printed in different styles to suit a variety of design aesthetics. From solid and traditional colors to stunning prints, designers have the ability to create a variety of styles.

Layering Versatility: WBF can often be combined with other fabrics, including insulation like down or synthetic insulation in addition to the lining. This allows designers to create jackets or coats suitable for unique climates and seasons.

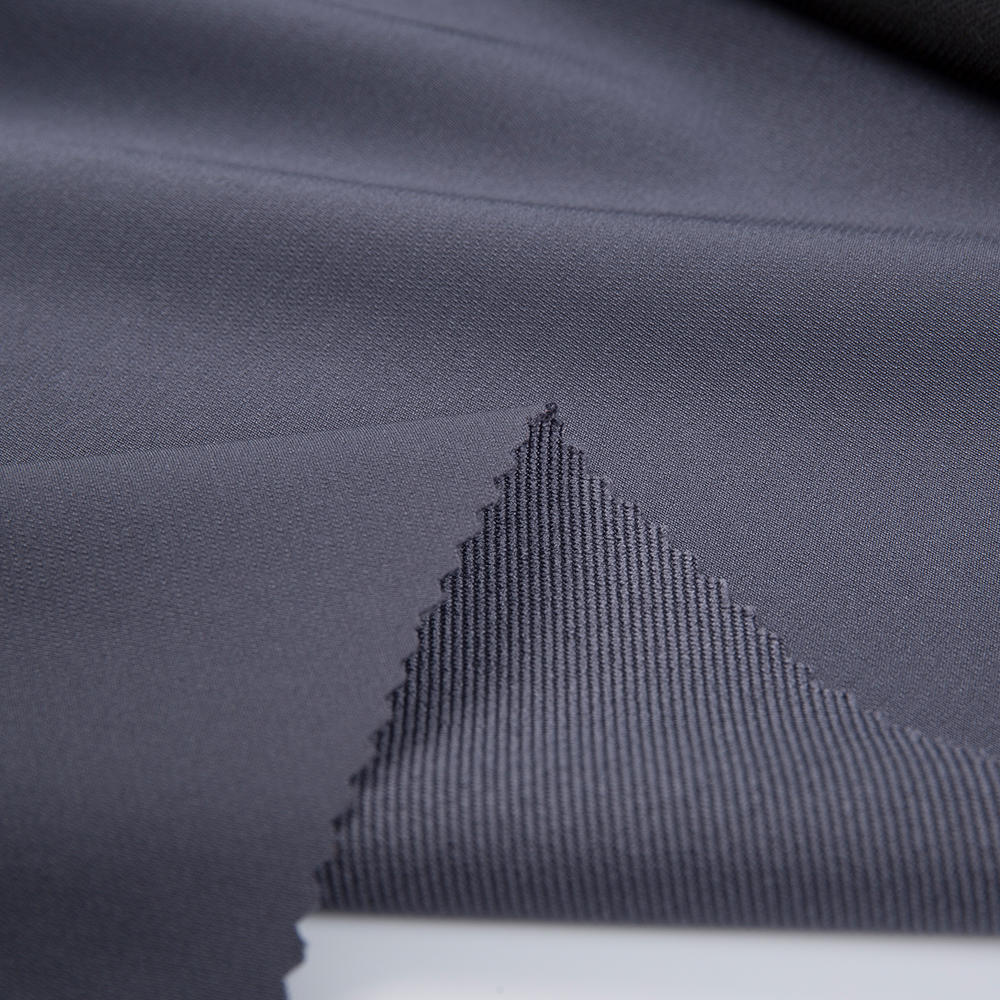

Cutting and stitching possibilities: WBF can be cut and stitched in a variety of ways to achieve special designs and styles, as well as custom jackets, unstructured outerwear or avant-garde silhouettes. The flexibility of the material makes it possible to experiment with a variety of shapes and details.

While WBF offers the versatility to adapt to different garment styles and designs, it is worth noting that certain design elements or construction techniques may need to be modified to accommodate the technical properties of the fabric, such as seam sealing for fully waterproof garments. Additionally, while WBF is breathable, it may not be as breathable as other natural or synthetic fabrics, which can be considered when designing for high-intensity or aerobic activities.

What technology does Waterproof Breathable Fabric for Coats and Jacketscaiyong use for waterproofing?

Waterproof and breathable fabrics used in coats and jackets are available in a variety of waterproofing technologies. Commonly used techniques include:

Membrane Technology: This involves the use of a thin microporous membrane inserted between the fabric shell and lining. The membrane has tiny pores smaller than water droplets and larger than water vapor molecules. This allows the fabric to repel liquid rainwater and allow sweat vapor to escape.

Durable Water Repellent (DWR) Coating: This is a chemical treatment applied to the outer surface of a fabric. DWR helps make the fabric hydrophobic, meaning it doesn't absorb water but instead beads up on the surface and rolls off. Increases the waterproof ability of the fabric to keep the wearer dry.

Nanotechnology: Nanoparticles can be embedded into fabrics to create a water- and stain-resistant surface. These nanoparticles form a barrier that allows water droplets to slide off the fabric without being absorbed.

Lamination Technology: In this method, a waterproof breathable membrane is applied inside the outer fabric layer. This prevents water from penetrating the fabric but allows water vapor to pass through.