Sustainable practices in the production of nylon spandex fabrics are gaining traction as the fashion and textile industries increasingly prioritize environmental responsibility. Here are some key emerging practices:

Recycled Materials

Recycled Nylon: Many manufacturers are now producing nylon from recycled materials, such as discarded fishing nets and fabric scraps. This reduces reliance on virgin petroleum-based resources and lowers the environmental impact.

Recycled Spandex: While spandex recycling is still in its infancy, some companies are exploring ways to recycle spandex fibers, contributing to a more circular textile economy.

Eco-Friendly Production Processes

Reduced Water Usage: Innovations in dyeing and finishing processes aim to minimize water consumption, which is a significant concern in traditional textile manufacturing.

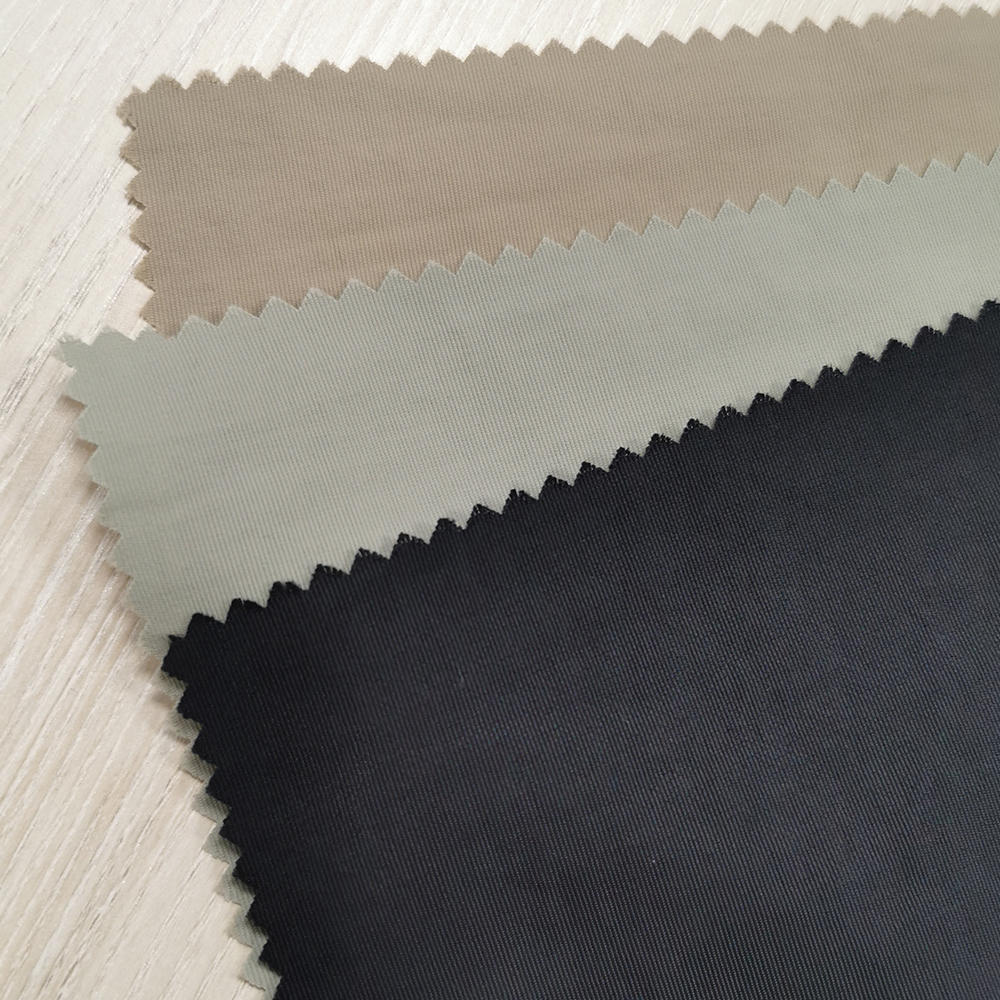

Low-Impact Dyes: The use of low-impact, non-toxic dyes helps reduce the environmental footprint of the dyeing process, making fabrics safer for both the environment and workers.

Sustainable Manufacturing Practices

Energy Efficiency: Manufacturers are adopting energy-efficient technologies and renewable energy sources in production facilities to decrease greenhouse gas emissions.

Waste Reduction: Many companies are implementing strategies to reduce waste throughout the manufacturing process, such as using cutting-edge technology to minimize fabric scraps and recycle production waste.

Certifications and Standards

Sustainable Certifications: Brands are increasingly seeking certifications, such as Global Recycled Standard (GRS) or OEKO-TEX Standard 100, which verify that fabrics meet specific environmental and social criteria.

Transparency and Traceability: More brands are focusing on transparency in their supply chains, allowing consumers to trace the origin of materials and production methods.

Innovative Alternatives

Bio-based Materials: Research is being conducted into bio-based alternatives to traditional nylon and spandex, such as fibers derived from plant sources, which could offer similar performance characteristics with a lower environmental impact.

Circular Economy Models: Companies are exploring business models that promote recycling and resale of garments, encouraging consumers to return used items for recycling or refurbishment.

As the demand for sustainable fashion grows, the production of nylon spandex fabrics is evolving to incorporate more environmentally friendly practices. From recycling and eco-friendly production methods to innovative materials and transparent supply chains, these initiatives aim to reduce the ecological footprint of textile manufacturing while maintaining performance standards. The shift towards sustainability not only benefits the environment but also aligns with the values of increasingly conscious consumers.