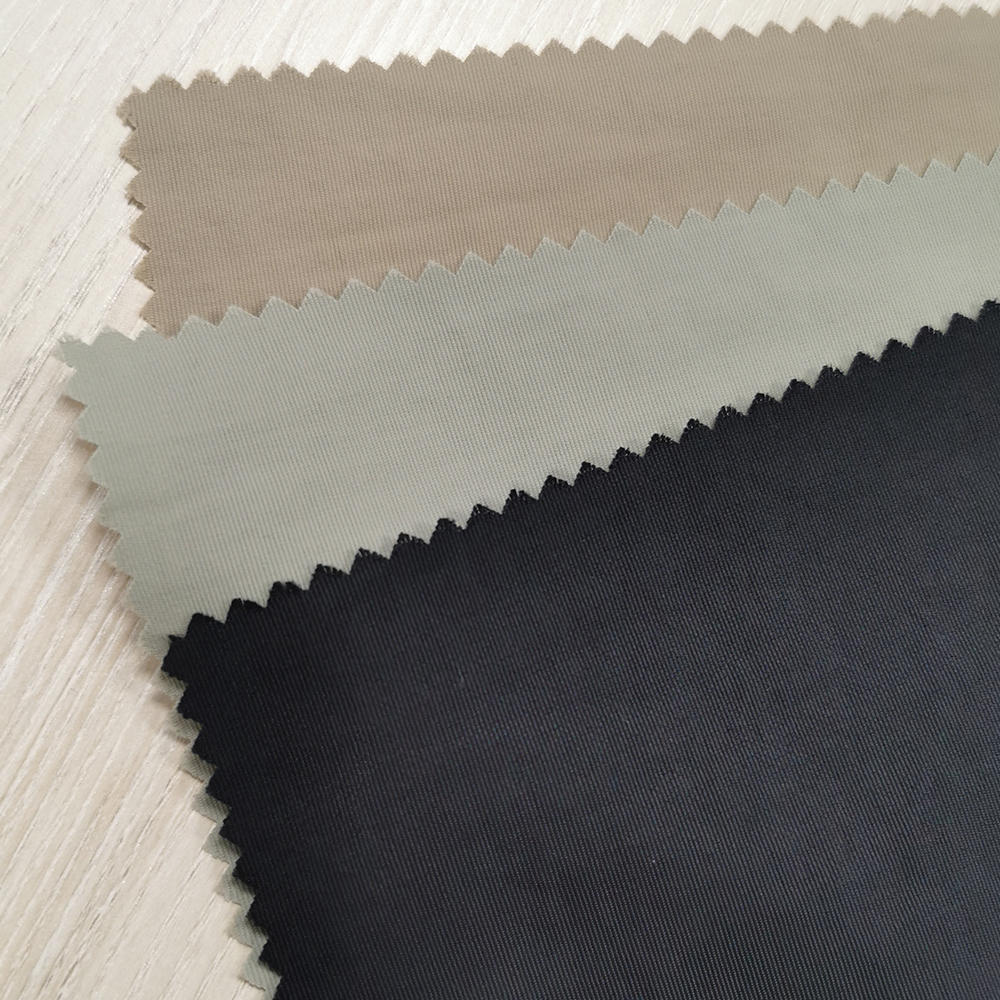

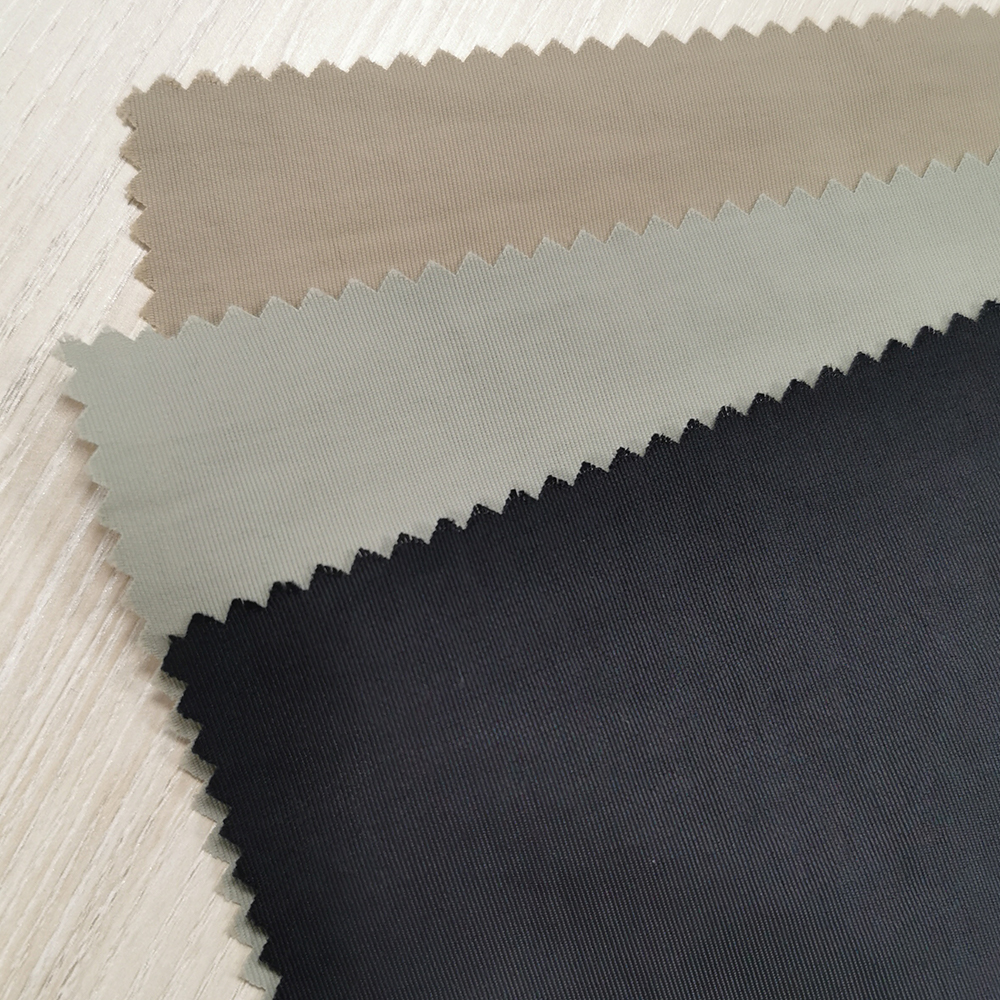

Nylon Taslon fabric is known for its robust performance in terms of resistance to tearing, puncturing, and other forms of wear and tear. Here’s an overview of its characteristics:

Tear Resistance

High Tensile Strength: Nylon Taslon fabric is made from high-tensile-strength nylon fibers, which contribute to its resistance to tearing. This makes it suitable for applications where durability is critical, such as in outdoor gear or workwear.

Ripstop Variants: Some versions of Taslon fabric incorporate a ripstop weave, which further enhances tear resistance by preventing small tears from spreading.

Puncture Resistance

Tight Weave Structure: The fabric's tight weave helps to resist punctures from sharp objects. While not completely puncture-proof, it offers a good level of protection compared to lighter or more loosely woven fabrics.

Enhanced by Coatings: If the fabric is treated with a durable water-repellent (DWR) coating or other protective finishes, its resistance to punctures and abrasion can be further improved.

Abrasion Resistance

Durable Surface: Nylon Taslon is designed to withstand abrasion, making it ideal for applications where the fabric will be in contact with rough surfaces or subjected to frequent friction.

Longevity: The fabric maintains its integrity over time, even with regular use in harsh environments, ensuring a long lifespan for products made from it.

General Wear and Tear

Everyday Durability: Nylon Taslon is resistant to everyday wear and tear, such as rubbing, stretching, and general handling. This makes it a popular choice for items like jackets, backpacks, and other gear that require durability without sacrificing comfort.

Maintenance: Regular care, such as avoiding excessive exposure to sharp objects and following proper washing instructions, can help maintain the fabric’s resistance to wear and tear.

Nylon Taslon fabric is well-regarded for its durability, making it a reliable choice for products that need to withstand tough conditions while providing longevity and performance.