The molecular structure of Thermoplastic Polyurethane (TPU) plays a crucial role in determining its flexibility, durability, and chemical resistance. Here’s a detailed explanation of how the molecular structure of TPU contributes to these properties:

Molecular Structure of TPU

TPU is a type of polyurethane that consists of both hard and soft segments. The molecular structure of TPU can be broken down into the following components:

Hard Segments:

Isocyanates: These are the reactive components that form the cross-links in the polymer structure. Common isocyanates used in TPU include methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI).

Chain Extenders: These are small, reactive molecules that link the hard segments together. Common chain extenders include diols (e.g., ethylene glycol, butanediol) and diamines (e.g., ethylenediamine, hexamethylenediamine).

Soft Segments:

Polyols: These are long, flexible polymer chains that provide elasticity and flexibility to the TPU. Common polyols include polyether polyols (e.g., polyethylene glycol, polypropylene glycol) and polyester polyols (e.g., polyethylene adipate, polybutylene adipate).

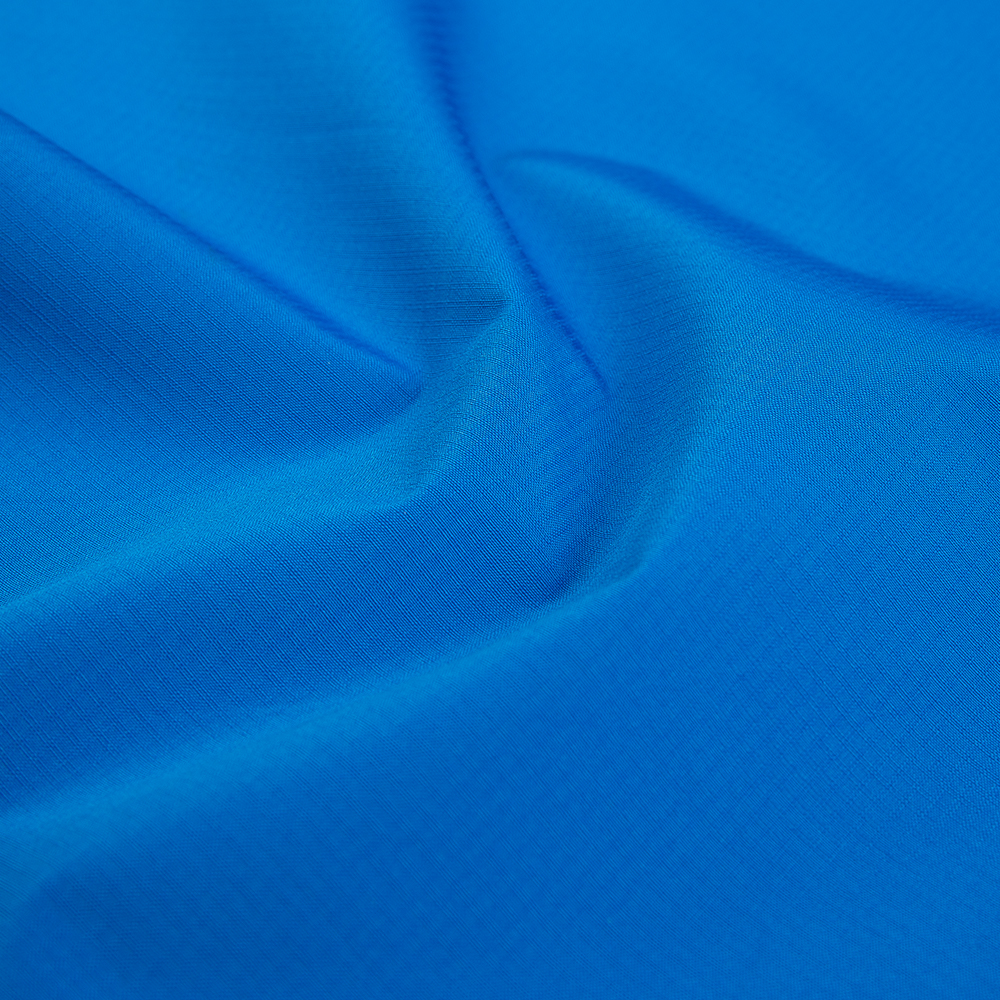

Flexibility

Soft Segments: The flexibility of TPU is primarily due to the presence of long, flexible polyol chains (soft segments). These chains can move and slide past each other, allowing the material to bend and stretch without breaking.

Polyether vs. Polyester Polyols: Polyether polyols generally provide better low-temperature flexibility and hydrolytic stability, while polyester polyols offer higher mechanical strength and thermal stability.

Durability

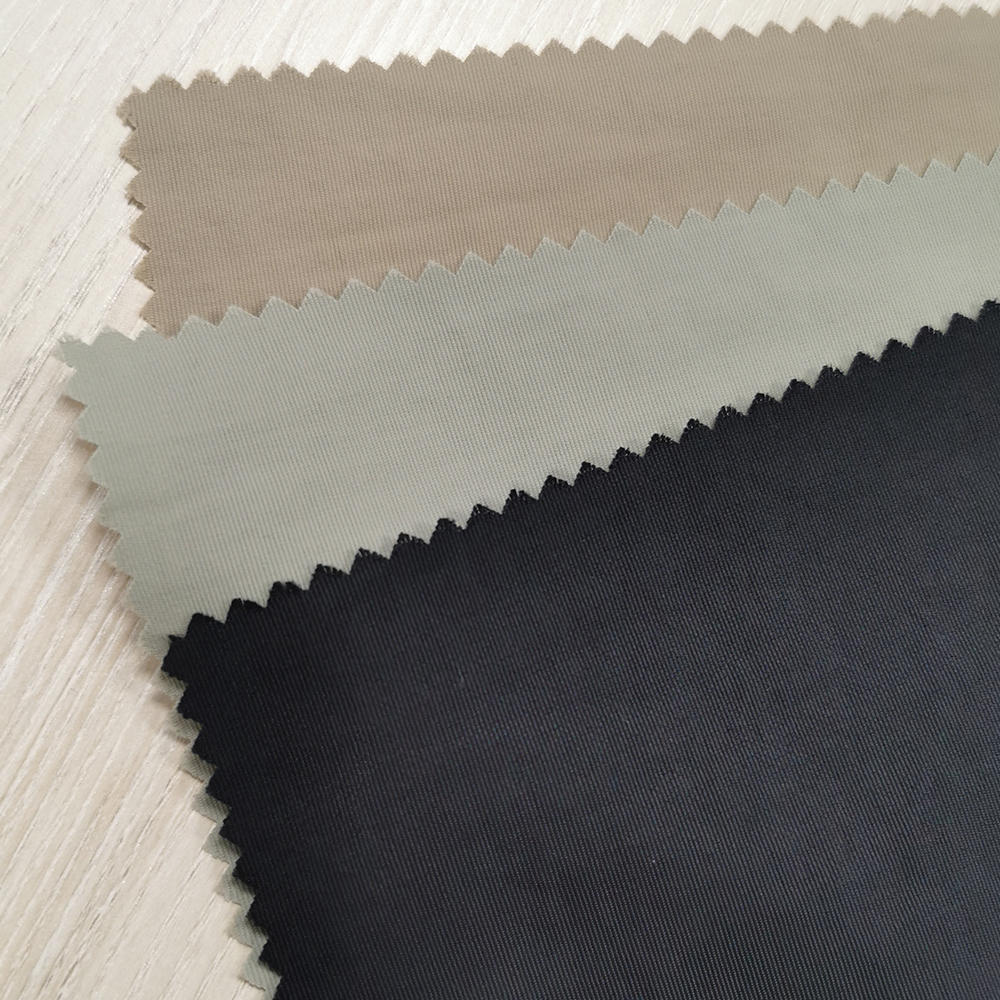

Hard Segments: The hard segments in TPU laminated fabric, formed by the reaction of isocyanates and chain extenders, provide mechanical strength and durability. These segments form a network that reinforces the soft segments, enhancing the overall toughness of the material.

Cross-Linking: The cross-linking density of the hard segments can be adjusted to control the mechanical properties of TPU. Higher cross-linking density generally results in increased strength and durability but may reduce flexibility.

Chemical Resistance

Chemical Structure: The chemical resistance of TPU is influenced by the specific types of isocyanates, polyols, and chain extenders used in its formulation. For example, aromatic isocyanates (e.g., MDI) generally provide better chemical resistance than aliphatic isocyanates.

Polyester vs. Polyether Polyols: Polyester polyols offer better resistance to oils and greases, while polyether polyols provide better resistance to hydrolysis and microbial attack.

Chain Extenders: The choice of chain extender can also impact chemical resistance. For instance, diamines can provide better resistance to certain chemicals compared to diols.

Customization and Formulation

Tailored Properties: The molecular structure of TPU can be tailored to achieve specific properties by adjusting the ratio of hard to soft segments, the type of polyol used, and the choice of isocyanates and chain extenders.

Performance Optimization: By carefully selecting and balancing these components, TPU can be formulated to meet the specific requirements of various applications, such as high flexibility for sportswear, high durability for industrial applications, or high chemical resistance for protective gear.